Meat and wool are equally important products of sheep farming, for which animals are bred all over the world. Products made from sheep wool are in constant demand, especially in cold regions. Sheep breeders must be able not only to feed and care for the herd, but also to obtain and process wool raw materials. Let's consider what to do with the wool of domestic sheep after shearing, so as not to lose a valuable product and have a profitable production.

- Types of wool raw materials

- Features of sheep wool processing

- Fine-wool direction

- Semi-fine-fleece direction

- Semi-coarse-haired direction

- Coarse-haired direction

- Processing tools

- Shearing

- Further processing

- Automation of the production process

- How to choose the right breed

- How to create a sheep wool processing business?

- Making things

- Modern market trends

Types of wool raw materials

The value of sheep wool is determined by its excellent spinning properties and the ability to turn into felt during processing. Sheep breeds have been developed with different wool characteristics. The following types of raw materials are in demand:

- Uniform wool. The advantage is the same type of fibers (down, transitional). Fine wool of merino and non-merino breeds is used to make thin wool threads for clothing, interiors, bed textiles, and fine sanding.

- Semi-thin. Obtained from semi-fine fleece sheep and crossbred breeds. The output of processing is fine-wool felt, used in the shoe and clothing industries for sanding.

- Semi-rough. Composition: awn, fluff, transitional fibers. They make felt for mechanical engineering and shoe making.

- Rude. Contains all possible parts of sheep hair. Depending on the timing of the haircut, the composition and quality vary. Technical felts are made from coarse wool.

Main characteristics of wool:

- fineness (fine wool - from 25 microns and less);

- length;

- tortuosity.

Fine and semi-fine wool sheep grow well in the Russian climate. Wool is in constant demand, so private farms produce raw materials for sale or bring finished products to the market.

Features of sheep wool processing

Depending on the type of raw material obtained from sheep, the methods and features of processing are determined.

Fine-wool direction

The thinnest fibers have a thickness of 10-14 microns, according to directional standards - no more than 25 microns. In this case, the length varies between 75-100 millimeters. The raw material consists of one down, which has a white or close to white color. Such raw materials are obtained from fine-wool sheep:

- Rambouillet;

- Australian merino, Soviet;

- Kazakh;

- Krasnoyarsk;

- Stavropol

The highest quality fibers are demonstrated by New Zealand and Australian merino wool; their wool is considered standard due to its elasticity (up to 20 thousand folds without breaking). Fine wool raw materials are used to make luxury clothing; the products are warm, delicate, light and soft. From one sheep per year, 4-6 kilograms of wool of the highest quality are sheared.

Semi-fine-fleece direction

The raw material of semi-fine wool contains more hair than fluff. The raw material standard is 26-40 microns. Best breeds:

- corriedale;

- half-vars;

- Lincoln;

- Romney March.

It is not used to make premium clothing; wool is used to produce felt.

Semi-coarse-haired direction

The raw material contains a lot of transitional hair, in addition to fluff, there is also a soft awn. Sheep are meat-wool breeds and produce a lot of fat. Representatives:

- Altai;

- Tajik;

- Armenian

Wool is used in the production of blankets, carpets, and felts. The highest quality types of this raw material are used in the manufacture of fabrics (Cheviot, Boston). Farmers should be aware that this area of sheep breeding predominates in Russia, and problems with sales are possible.

Coarse-haired direction

Karakul, Smushkova, Romanovskaya sheep are representatives of the coarse-wool trend. All wool is used without rejection; the raw material combines fluff and coarse hair of different colors. Sheep are bred for meat and milk; wool is not the main purpose of the breed. The fibers reach 60 microns in diameter, are coarse and hard.

They produce felt, which is in demand in industry and in the production of footwear. The rough material has high strength and does not pill.

Processing tools

Sheep owners must provide equipment on the farm for obtaining and processing wool, as well as a dry warehouse for storage. For large herd sizes, mechanized shearing and processing methods are useful.

The simplest set of tools:

- clipper or scissors;

- combs made of wood;

- device for combing wool (carder);

- spindle, spinning wheel for making yarn;

- loom.

Processing raw materials requires special skills; in many small farms it is still done by hand.

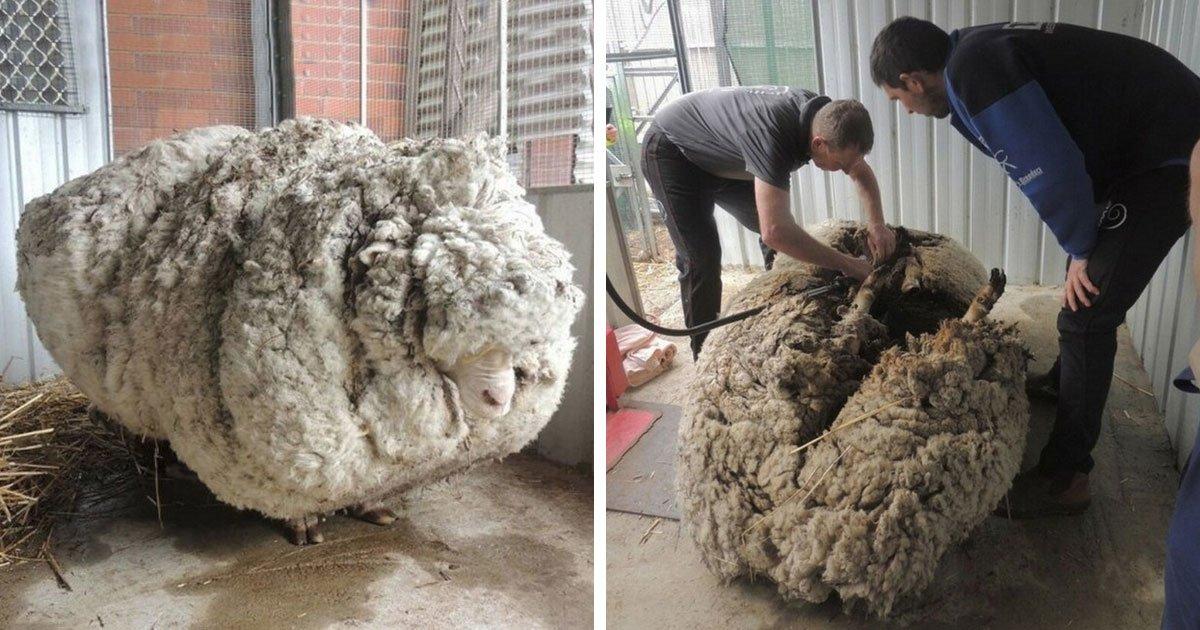

Shearing

The cutting time is chosen depending on the breed and the readiness of the coat. Basic Rules:

- fine-fleece and semi-fine-fleece - spring, once a year;

- coarse-haired and semi-coarse-haired – spring, autumn (twice).

Fine-wool breeds do not shed, so there is no hair loss. The time for cutting is chosen when the wool becomes softer after winter and grease has accumulated.

For beginners at home, it is important to master shearing techniques and rules for handling sheep, so as not to spoil the wool and harm the animal. Subsequence:

- the sheep is placed on its side and its legs are tied;

- cut from the stomach and groin to the chest, protect the nipples with your hands;

- stray areas of wool are cut off with scissors and removed so that they do not interfere with the making of yarn;

- turn the sheep over, shear the other side;

- they plant the sheep, hold the head, remove the wool from the back;

- the neck is cut from the head to the body.

The animal is freed from its fetters, the clipped material is sorted and stored on a tarpaulin or the cleaned floor of the barn before primary processing.

Further processing

After the haircut, do:

- combing and removing dirt;

- drying and frying until the characteristic odor is removed;

- washed, degreased, dried;

- comb and beat for softness and shine.

The pure fleece is then made into thread (spun) or felt.

Automation of the production process

Manual processing is possible only with small volumes of wool. To mechanize the process, special equipment is used, which increases the cost of production, but helps process a significant amount of raw materials and, as a result, makes the farm profitable.

For automation the following are used:

- line for washing and cleaning fleece from fat and impurities;

- apparatus for removing tangles;

- washing machine and dryer;

- spinning machines;

- packers.

All devices can be connected using a conveyor and an automated yarn production process is obtained. The initial costs are paid off by the speed and quality of the final product.

How to choose the right breed

When choosing a breed for obtaining raw wool, the cut from the individual and the quality of the resulting fleece are taken into account. Traditionally, fiber from fine-fleece and semi-fine-fleece sheep is in high demand on the market. How much can you get per year from an animal:

| Breed | Annual cut in kilograms |

| Lincoln | 6-10 |

| Merino Soviet

Australian Altaic Ascanian |

8-12

5-10 10-12 7-16 |

| Mazaevskaya | 6-12 |

| Novokavkazskaya | 6-9 |

| Kuibyshevskaya | 5-6 |

| Karakulskaya | 3.5-5 |

| Romney March | 8-9 |

The fleece of long-haired breeds is in demand on the market; the fibers have shine and high wear resistance. Russian Longhair and Lincoln are prized for their soft, curly hair. Lincoln sheep love cool weather and grow well only under certain conditions. The yield of cleaned fleece is 55-60% of the weight of the fleece.

Russian longhairs are less capricious in grooming.They are distinguished by good health, unpretentious, and produce 3.5-6.5 kilograms of high-quality wool.

You can get high-quality fleece from sheep of the Romney-Marsh, Kuibyshev, and Tien Shan breeds. Sheep of hybrid species are distinguished by their endurance, high-quality thin wool, and undemandingness in food. Tien Shan sheep can feed on pasture all year round in warm regions.

How to create a sheep wool processing business?

A business for the production and processing of wool sheep raw materials can be organized in several options:

- Organization of our own sheep farm and processing workshop.

- Procurement (reception from the population) of raw materials, primary processing, delivery to Russian factories or for export.

- Mini-factory for raw materials procurement and processing for local sales.

- A full-cycle plant with spinning capacity - in an area with a large number of sheep farms and the possibility of mass purchasing of raw materials.

The demand of domestic factories for wool is great; raw materials of any quality are purchased for various needs. A mini-factory (processing workshop) requires a small area, the number of workers is 5-30 people.

Advice: you can supplement your processing production with lines for felting, felt making, and a spinning workshop.

Making things

Forward-thinking owners complement small factories for processing raw materials with workshops for the production of finished products. Handmade work adds exclusivity to the products; craftswomen create real masterpieces from felt, felt, and knit unique products from spun thread. The following types of products are in demand:

- medical purposes – belts, joint pads, socks;

- handmade kits;

- blankets, rugs;

- felt winter shoes, outerwear;

- bath accessories;

- felt for making hats and other products;

- soft slippers.

Designer products are complemented with embroidery and decorated with beads. The fashion for natural materials is constantly growing. The obvious handiwork, some simplicity of design and form do not spoil such items, but increase the cost.

Modern market trends

All types of sheep wool are in demand on the market, while sheep breeding in Russia is poorly developed. There are usually no problems with selling goods from sheep farms. Selling finished products is always more profitable than selling raw materials, so wool processing production would be useful.

Own raw materials will increase the profitability of the mini-plant. Before creating a business, it is important to make sure that the final product is in demand, is in demand on the market, and its price will cover the costs. The plant capacity must correspond to the amount of raw materials (outsourced purchases).

When starting a wool processing business, you need to find suppliers of raw materials and buyers of finished products. Such plants quickly pay for themselves in sheep-raising areas where farmers sell their wool. Your own sheep farm will provide production with constant raw materials and the possibility of additional income from meat.