This aromatic, low-alcohol drink, which dates back thousands of years, is popular with hundreds of millions of people. The desire to preserve wine for a long time without changing the taste and aroma became the reason for its heat treatment. Pasteurization of wines from any raw material and strength is used by amateur winemakers. In the wine industry, sulfites are used to preserve the product.

History of origin

Louis Pasteur discovered a method to combat wine diseases at the request of French winemakers in the mid-19th century. He proved that the cause of souring and the appearance of mold are microorganisms that feed on wine sugar. When heated to 50-60 degrees they die. Spores are more resistant to high temperatures, which can only be destroyed by sterilization: heating to 100 degrees or higher.

Why is wine pasteurization necessary?

Pasteurization of wine is necessary to destroy bacteria and yeast. Each type of wine requires its own temperature and aging period. For grape wines, it also depends on the degree of sweetness: dry, semi-sweet, sweet.

When you might need it

Microorganisms develop within 6 months. If the wine is used before this period, it will not be pasteurized.

Varieties of the method

In practice, several pasteurization methods are used:

- long-term;

- short;

- instant.

During long-term pasteurization, the liquid product is heated at a temperature of 60 to 65 degrees for half an hour to forty minutes. Short pasteurization means heating to 80-90 degrees for 30-60 seconds. Instant lasts 3-5 seconds at a temperature of 98 degrees.

At home, long-term pasteurization is used for wine to avoid the appearance of a compote taste in the drink.

How to pasteurize wine at home

Any wine can be subjected to pasteurization at any aging period:

- grape;

- apple;

- cherry;

- currant;

- cherry;

- young;

- seasoned.

The pasteurization process goes through several stages that must be strictly followed.

Product preparation

The wine must be pre-cleaned to remove yeast and turbidity.Bentonite clay or gelatin is used as a clarifier. Then you need to let it settle for sediment to settle.

After sedimentation of the turbidity, the wine is poured into a container in which it will be pasteurized and stored. These should be glass bottles or jars that have been heat-treated with steam or boiling water. To avoid air getting into the wine and its further release during heating, use a plastic tube with a diameter of 1 centimeter.

The tube is lowered into a container with wine to a level 1-2 centimeters above the sediment. A vacuum is created in it and poured into the prepared container.

Pasteurization process

In wine jars, the neck is closed with screw metal lids. Bottles are sealed with corks. The level of the drink in the can is up to the neck, in the bottle – 3-4 centimeters to the cork. Free space in the container during pasteurization is necessary for the expansion of the liquid during heating.

A wooden grate is installed in the pan or fabric is placed in several layers to insulate the glass with the hot metal. Place cans or bottles. To control the temperature, you need a jar filled with water, placed next to the wine containers.

Containers with bottles/cans are filled with water to the level that the wine will have when heated. The fire turns on medium.

Bottle holding time:

- 0.7 liters – 1/3 hour;

- 0.5 liters – ¼ hour;

- 1 liter – 25 minutes.

The pasteurization temperature depends on the strength of the drink (degrees):

- for dry – 55;

- semi-sweet – 60;

- sweets – 65.

A water thermometer measures the temperature in a jar of water. At the end of pasteurization, the fire is removed. Bottles of wine are cooled in a pan of water to 30 degrees, after which they are put away in a cool, dark place.For better tightness, the plugs are covered with sealing wax on top.

Wines packaged in cans are pasteurized in the same way as bottles:

- installed in a container;

- fill the container with cold water above the hanger;

- turn on medium heat;

- kept at a temperature of 60 degrees for 35 minutes;

- cool at room temperature.

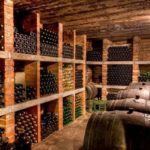

Storage of wine product - in a dry, cool place with ventilation.

Other ways to fix wine

Amateur winemakers use pasteurization methods that differ from traditional ones. For example, they use homemade containers made of stainless steel or aluminum.

Without fail, the wine, as with conventional methods, must be cleared of tartar and sediment. A homemade stainless steel pan can have a volume of up to 20-30 liters. Pour the drink through the hose. For speed, connect a pump from the aquarium.

Temperature control is carried out using a thermometer with a remote sensor.

The meter is placed on the lid of the container. The pan filled with wine is placed on the stove. Gas burners provide uneven heating. The optimal solution would be to use an electric stove whose burner size matches the bottom of the pan.

Based on the readings of the thermometer, keep the wine at 65 degrees for 30 minutes. Electronic devices produce results with an error of 0.2-0.3 degrees in the direction of overestimation. The actual temperature of the wine during pasteurization will be 62-63 degrees.

With this pasteurization method, cold filling is used. The wine in a stainless pan is cooled to room temperature. Bottles heated to 150 degrees for 15 minutes should cool to 20-22 degrees.

To pour pasteurized wine, there is a tap at the bottom of the homemade pan.A sterilized adapter and a piece of polyethylene tube are put on it, through which the bottles are filled with wine to the level of the cork.

How to sterilize wine bottles

You can prepare bottles for bottling pasteurized wine in several ways: traditionally (in a saucepan), or using an electric oven.

Sterilization in a container is carried out without a thermometer. Cleanly washed bottles are filled with warm water up to the hangers and placed on a tray in a container, the edges of which should be higher than the bottles. Fill with water at 40-50 degrees to the level of the hangers. Turn on the heat and bring to a boil. When the water boils, reduce the heat to ensure even boiling.

The sterilization time is counted from the moment of boiling in the container. For bottles, 10-15 minutes is enough. Then the fire is turned off. The bottles are removed, the water is poured out of them, and turned upside down over a clean cloth. After draining the water, place it upside down and cover with a sterile towel.

Dry sterilization in an electric oven is no less effective if you keep the washed bottles at temperatures up to 150 degrees for 10 minutes.