After slaughtering a pig, the first and most important procedure is singeing the carcass. Heat treatment is necessary before cutting, so that the meat is then edible. In meat processing plants, this stage includes softening the skin by scalding in boiling water, removing bristles using a scraper, and curing the carcass in a scorch oven. At home, there are several ways to singe a pig or pig without special equipment.

Why do you need to scorch?

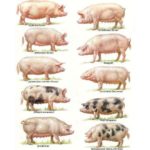

Pig skin appears pink and smooth in appearance. In fact, it is covered with small, hard bristles. The hair varies in length and color among different breeds of pigs. The condition of the stubble is also affected by living conditions and nutrition.

The skin of a slaughtered pig or piglet is singed for the following reasons:

- the carcass without bristly cover acquires a marketable appearance;

- skin and meat are stored longer after searing;

- Lard develops a specific taste and aroma.

Once seared, the pig is ready for further cooking. It is recommended to salt or smoke the carcass immediately after heat treatment. If you do not singe the skin in time, then the bristles cannot be removed. The lard is located close to the skin and partially withers, and after salting it smells deliciously like smoke.

Hypothetically, piglets need not be singed. Their bristly cover is not as hard as that of adult animals. Before cooking meat, just remove the skin. But as a separate product it will not be suitable for use.

After singeing, pig skin is processed and used in furriery. It produces a smooth, durable and elastic material for outerwear and accessories.

Stubble removal methods

Farms usually do not have special equipment for scraping and singeing carcasses. Furnaces and scrapers are essential in continuous production. When slaughtering small quantities for personal use or for sale, pigs are singed using folk methods and improvised means.

Farmers use three methods:

| Searing method | How to do it | What gives |

| Gas burner | Gradually every centimeter of the skin is burned | Cleans folds and hard-to-reach places |

| Straw | The carcass is placed on straw and the litter is set on fire. | Effortless processing |

| Blowtorch | The skin is gradually processed, just like with a gas burner. | The most thorough removal of stubble, deep treatment of skin and sebum. |

| Scalding | The carcass is immersed in water heated to high temperature. | An easy way to clean a pig's skin |

With each method, it is important not to dry out the pig’s skin, and when keeping it in boiling water, not to cook the carcass completely. In addition, the bristles can be etched with chemicals. But this method is dangerous to health.

Leather treated with the chemical will still not be usable. There is a risk that some of the substance will penetrate into the lard and spoil the product.

How to properly singe a pig with a gas torch

The method is considered the most effective for processing a pig or piglet, although it requires time and attention. The gas burner does not heat up, so it is safe to use for long periods of time. You can assemble the device yourself.

Carcass singeing process:

- place the pig on a flat wooden or heat-resistant surface;

- turn on the burner and fire over the skin;

- hold the burner on one area until the skin turns black;

- To make the work progress faster, you can increase the heat, but it is important not to burn the skin and fat;

- If bubbles of boiled fat appear, then the area is sufficiently scorched.

It is recommended to carry out the procedure twice: burn until there is a black coating, scrape it off and burn again. As singeing progresses, the pig is turned from side to side. Periodic wetting with water will help prevent drying of the skin. It cracks due to intense heat.

Finally, the black coating and stubble are scraped off with a knife and metal sponges. The skin on the belly is more delicate, so you need to singe and clean it carefully.

Singing a pig with a gas torch is a labor-intensive process, but the bristles are removed in the skin folds, behind the ears, and around the limbs.

How to make a gas burner for processing pigs

It is possible to assemble a pig singeing apparatus at home. For assembly you will need:

- two brass rods with a diameter of 2 centimeters;

- metal rod;

- heat-resistant handle, for example, from a soldering iron;

- rubber hose for gearbox.

The main parts of a gas burner: body, nozzle, reducer, gas supply regulator, fuse. Assembly steps:

- a body is formed from one brass rod;

- four holes are made in the second rod - a divider is made;

- connect the body and the divider, install the flange inside, leaving a gap;

- a blind hole with a diameter of 2 millimeters is drilled in a metal rod - a nozzle is made. Separately, make a jumper with a 4 mm hole. Both parts are caulked using a hammer and sanded with emery;

- the rubber hose is connected at one end to the body and at the other to the gas cylinder.

To assemble a gas burner, improvised materials are suitable. Only it is better to take the gas supply hose from a specialized material so that there is no leakage. Manufacturing the apparatus requires skill, so it is better to use a factory-assembled burner to singe a pig.

How to singe a pig or pig with straw

A simple rustic method is suitable for singeing carcasses that will be used for personal needs. The stubble is cleaned in large areas, but remains in the folds. The carcass is scorched unevenly, so it looks worse than after treatment with a torch.

Stages of singeing a pig with straw:

- the carcass is placed on its side on a free plot of land;

- lay a layer of straw on top and set it on fire;

- knock down too strong a flame with burlap rags;

- the ashes are shaken off, the bristles and fumes are cleaned off with a scraper;

- turn the carcass over and repeat the steps again.

The main trick is to lay out the straw in an even, not too thin layer, so as not to burn the skin. Pig and piglet can also be singed with aspen sawdust, but they produce a higher temperature. An indicator of readiness is bubbles of fat on the skin, as when processed with a burner.

A pig singed in straw should be more thoroughly scraped of bristles. Hard scrapers and a knife are suitable for this. Places in which hard hairs remain are pinpointed again with tufts of dry grass and set on fire.

How to tar a pig or pig with a blowtorch

The method is as effective as scorching with a gas burner. But working with a blowtorch will take a long time. For combustion, not oxygen, but propane gas is used. A blowtorch heats up, unlike a torch. Therefore, you will have to work intermittently. But the pig will acquire a presentable appearance, and the skin will be processed deeply and evenly.

Searing stages:

- place the pig on its side on a flat surface;

- turn on the blowtorch at medium temperature, if necessary, increase the burning intensity;

- pass the flame over the skin until it begins to darken and bubble;

- During breaks, clean off the stubble.

It is also recommended to singe the pig with a blowtorch twice, removing some of the hair and soot. It is also important not to dry out the skin during the process. The ears, tail, and skin folds will require more attention.

The singed skin becomes covered with a coal-black coating. It is cleaned off with a sharp knife, being careful not to cut off the skin. If large bubbles appear from the heat, they should be pierced immediately and ice applied. It is important to treat every area of the skin, otherwise the pig will be covered in places with blue spots and will lose its presentation.

How to singe a pig to add flavor

In order for the meat and lard to acquire a pleasant smoky smell, the carcass is scorched again after cleansing the bristles. The scraped pig is washed and roasting begins again. It is best to use a gas torch or blowtorch for re-searing.

How to make a pig flavorful:

- lay the carcass on its side and burn it in the same way as before;

- during the process, the skin is moistened with water so that it retains its elasticity and does not crack;

- turn the pig over, trying to process it evenly, otherwise the taste of meat and lard from different parts will differ;

- The stomach burns less than the legs and back.

Using high heat from a burner or lamp, the hooves are heated and removed. All procedures must be carried out with gloves. After repeated singeing, the carcass is ready for cutting. A delicious aroma will emanate from it.

It is recommended to salt or smoke meat and lard immediately after searing and make minced meat. Also, pork products do not have to be cooked, but stored in the freezer.

Removing stubble using scalding method

Scorching with a torch, blowtorch and straw can be carried out some time after slaughter. Scalding is also a good way to remove hair from hard-to-reach places, but it only works if you place the carcass in hot water right away.

The method is inconvenient to use for large pigs. It is best to scald piglets. Another inconvenience of this method is that the water must be close to the boiling point, but not boil.

How the process works:

- pour water into the vat and heat it to a temperature of 75-85 degrees Celsius. The landmark is barely bearable if you put your hand down. For accuracy, it is better to measure the temperature with a thermometer. The larger the carcass, the hotter the water;

- the pig is tied with a rope and lowered into a container of hot water, periodically turned and raised to the surface;

- When the bristles are easily pulled out of all parts, the carcass is finally removed.

The scalded pig is cleaned in the same way as after singeing - with a scraper or knife. The cooling carcass is watered with water at the same temperature as when soaking.

When scalding, it is important to ensure that the water does not boil, otherwise the skin will burst and the meat will cook. Finally, the piglet is washed to remove any remaining brushed bristles. In meat processing plants, scalded carcasses are additionally singed.