Malt is a sprouted cereal grain in which starch is transformed under the influence of enzymes into sugar needed to produce alcohol. In dry raw materials, minimal vital activity occurs. However, when moisture enters, special enzymes are activated, which trigger the growth and breakdown of starch. Malt is used to make many alcoholic beverages. That’s why many people are interested in how to make malt from wheat at home.

Peculiarities

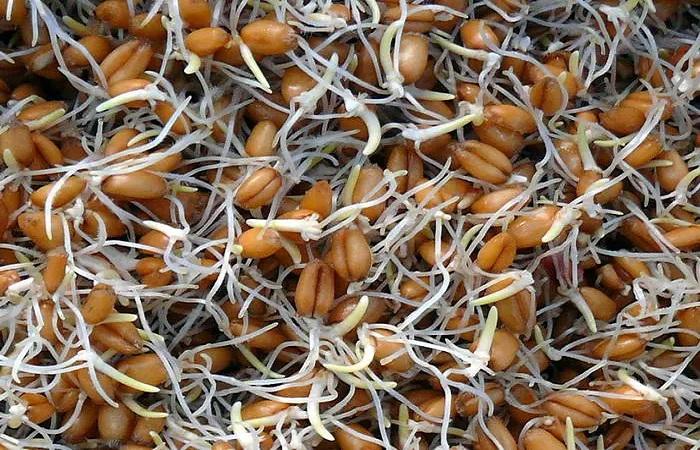

Wheat malt is sprouted cereal grains.During its preparation, starch is converted into sugar under the influence of enzymes. It is required for a complete fermentation process and a significant increase in the yield of the finished alcoholic product. To obtain high-quality malt, it is necessary to use only viable grains that can germinate.

How to make malt from wheat at home

Making a product from wheat has a number of features. To get a high-quality composition, you need to adhere to the basic rules.

Selection and disinfection

First you need to select raw materials. A batch of grain should be checked for germination parameters and the presence of toxins. Sprouted grains infected with a fungus will produce low-quality and even dangerous malt.

To check the quality of the beans, 100 pieces need to be soaked in water for several days. It is recommended to discard seeds that immediately float to the surface. They are empty and have no sprouts. If the germination rate of the remaining batch is up to 90%, this indicates its low quality.

Selected grains should be cleaned of contaminants and pathogenic microorganisms. To do this, it is recommended to do the following:

- Pour the raw materials into a large container and fill with water. It should be 6-7 centimeters higher than the grains. The water should be warm.

- After a few minutes, mix everything and collect any debris that has floated to the surface, and drain the water.

- Then pour cold water over the grain and leave for 1-1.5 hours. Remove the debris again and drain the water. These actions should be performed until the contaminants stop rising to the surface.

- Take a portion of fresh water and add disinfectant to it. For 10 liters you can use 2-3 grams of potassium permanganate or 30 drops of iodine. The grains must be kept in solution for 3 hours.Then the water can be drained.

Thanks to disinfection, it is possible to protect raw materials from mold. However, this stage is not considered mandatory.

Soak

The sorted wheat needs to be soaked. This helps eliminate another 40% of fungal spores. For maximum cleansing, the water needs to be changed several times during soaking. Wheat grains are most susceptible to fungi. Infected kernels become wrinkled and take on a grey-brown hue.

To soak the grains, it is recommended to do the following:

- Pour sifted and sorted grain with water and mix. Then remove all floating fragments and leave for half an hour.

- At the next stage, drain the water and leave for 10 minutes without water.

- Repeat the soaking and drying cycle several times.

- After the second cycle, take water at room temperature, add 25 drops of iodine for every 5 liters and pour over the wheat for 2 hours.

- Drain the liquid again and fill with cold water for 8 hours.

- Then drain the water and leave the wheat to dry for 8 hours.

- In total, do 4 more such cycles.

It is recommended to process grains within 3-4 days. This is done until the sprouts appear.

Wheat sprouting

Wheat germination occurs at a temperature of +15 degrees. It is important to maintain a stable temperature. To do this, the layer of grains needs to be stirred every 12 hours. It should be either thicker or thinner. As a result, you need to get grains of a sweetish taste with a crunch when biting and a cucumber smell.The sprout should be equal in length to the grain itself.

Drying, cleaning and curing

The kernels need to be dried by gradually increasing the temperature to the point at which the process stops. This point depends on the type of malt. The higher the temperature settings, the darker the beer will be.

Dried malt can be stored for at least 1 year. This is done in glass jars, textile bags or paper bags. Before drying, malt must be disinfected. The most harmless option is the use of potassium permanganate. To do this, you need to take 2-3 grams of disinfectant per 10 liters of water. You need to keep the malt in the resulting solution for 15 minutes.

To dry the product yourself, it is recommended to use the following methods:

- Place in an attic or balcony that is well ventilated. It takes 4 days to dry the raw materials in this way.

- Place under the flow of a room fan. This drying process will take 3 days.

- Place near the stove or radiator. The mass will dry for 3-4 days.

- Place in a vegetable dehydrator. The process will take approximately 40 hours.

- Place in the oven on a baking sheet. In this case, the grains need to be stirred every 3 hours. It takes up to 30 hours to dry the malt in this way.

The following signs will help you understand that the malt has dried out:

- grains have decreased in volume;

- became dry and hard to the touch;

- sprouts and roots are easily separated;

- when biting, you feel sweetness;

- humidity parameters are 3-3.5%.

The dried mass is called diafarin. After drying, the malt is rubbed by hand. This can also be done in a canvas bag. Then the mass is sifted from the sprouts and roots. This is the most suitable way to purify raw materials.

Malt grinding

Before using malt, it must be properly ground.It is not recommended to grind grains into flour. This will lead to big problems during filtration of the mash and will reduce the efficiency of wort preparation.

The best option is to use a special mill. It helps to properly process the malt without damaging its shell. This is of particular importance for complete extraction of substances. In addition, special mills are highly efficient. Even conventional mechanical products can produce up to 5 kilograms of crushed malt within an hour.

Further use

Finished caramelized malt is used to make homemade beer. It can also be used to make whiskey. To obtain the required result, it is recommended to first crush the raw materials. Ideally, it should be combined with other types of malt.

White malt is not suitable for making alcohol. It contains active enzymes. Therefore, this substance is used for so-called malting. 1 kilogram of product helps to saccharify up to 5 kilograms of starch-containing raw materials - flour or grain.