Setting up a beehive is important so that honey insects can store honey. Every experienced beekeeper knows why foundation is needed and what it is. And beginners in the field of beekeeping who are serious about engaging in this business need to study this issue thoroughly. After all, the honey “harvest” will depend on how well the hive is supplied with foundation.

What is foundation

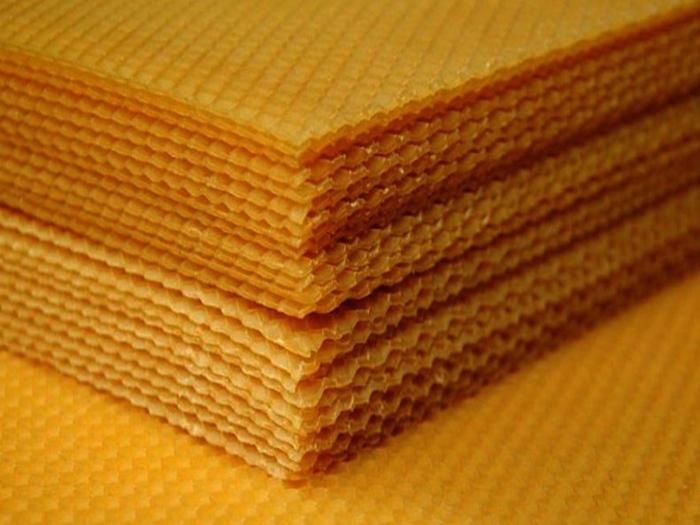

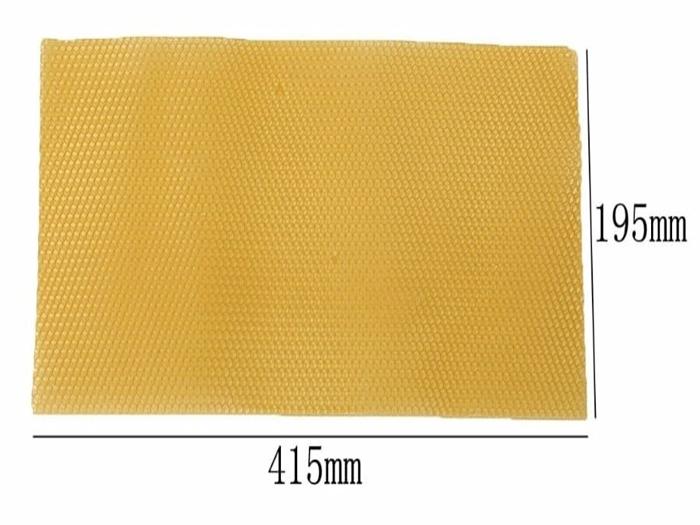

Foundation is beeswax that is inserted into frames.It looks like a plate on which insects create honeycombs, which are subsequently filled with honey. In beekeeping, two types of such material are used - natural and artificial.

On wax plates, hardworking bees build cells to build up a layer of honey in them at a record pace. One bee can build up to 4 thousand honeycombs per day! True foundation consists of white wax, which melts quickly when heated, but does not produce sediment.

Varieties and types

Foundations are classified into natural and artificial. In beekeeping, the second type of wax product is gaining popularity because it makes the work of bees easier. Although it is a copy of natural wax, there are differences between these two types of material.

Artificial

Artificial foundation is produced on an industrial scale at specialized enterprises. The process of its manufacture is regulated by Gosstandart. Based on the material used, the product is further divided into:

- Semi-natural wax. It is inferior in quality to natural material. Such a product is obtained by mixing wax with paraffin or other additives. This does not change its properties much, but it is a little more difficult to coat, and it is characterized by increased fragility.

- Polyurethane, plastic foundation. This is a completely artificial material, in the manufacture of which plastic is used. This material is characterized by the presence of ready-made honeycombs - the bees do not need to complete anything using wax. They only have to fill the created cells with honey. In addition, on the surface of such foundation there are already depressions for larvae with drones.

Artificial wax plates can be produced manually by a beekeeper. But this is complex, painstaking work that takes a lot of time.

Natural

Honey foundation made from natural material is highly valued by beekeepers. The production process occurs in two ways:

- The bees make the plates themselves from honey and pollen, then build the cells. By the way, earlier, before the appearance of the first artificial foundation, honey-bearing insects spent their own resources on building containers for the sweet mass. Because of this, honey supplies were scarce.

- The material for honeycombs is made by a beekeeper at home, or by factory workers. The result is wax made from natural raw materials, which was already mentioned earlier. In its production, exclusively pure and completely natural beeswax is used. If impurities are added to the wax mass during the production of plates, then the final production product cannot claim to be called natural.

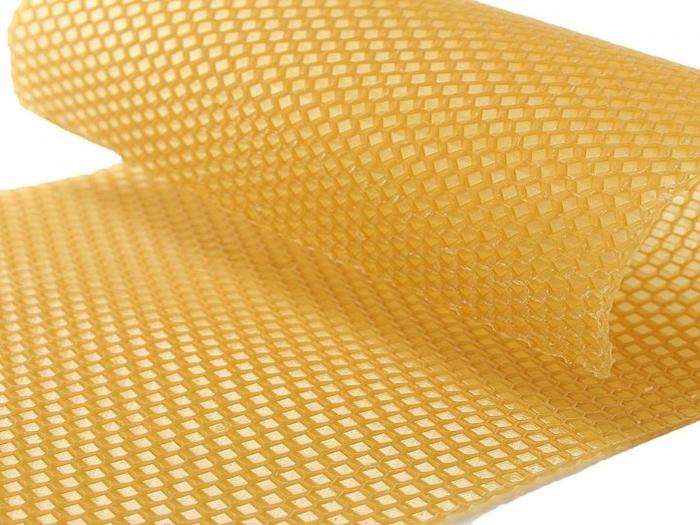

On a note. Natural wax plates are characterized by plasticity and a tendency to melt under the influence of high temperatures.

Therefore, they need to create special storage conditions so that they retain their suitability until the next honey harvest season.

How bees make wax

Bees use pollen in combination with honey to produce wax. Once they receive the building material they need, they immediately get to work.

But in order for insects to build sheets of foundation and honeycombs on them, the hives must have an optimal air temperature - from +25 to +30 degrees. If this indicator is lower or higher, the entire process of making wax layers will be stopped.

How does a person produce

The first artificial foundation was created in 1869. It was presented at the exhibition - and since then the technique of making such wax plates began to rapidly gain popularity.It developed and improved, changes were made to it, new processes and production stages were added.

Nowadays, foundation is produced by applying a honeycomb bottom configuration to a finished wax plate. It should be thin and consist only of natural raw materials. The use of any additional additives - paraffin, stearin or others - in this process is not recommended. But it is not prohibited. Plastic honeycombs, although they cannot boast of being completely natural, also have advantages.

This process can be done manually or automatically. In the first case, you can roll up to 20 kilograms of wax plates per day.

The automatic rolling method involves the use of an electric drive. This allows you to increase production tenfold, because the machine is capable of rolling up to 50 kilograms of raw materials in just 1 hour! And when using innovative equipment with improved lines, the volume of processed material reaches 100 kilograms in 1 hour.

Application

Foundation is used not only in beekeeping. It is also used for other purposes:

- candle making;

- creating decorative elements - artificial flowers, various figures, figurines, souvenirs;

- obtaining medicines: treatment using bee products even received a separate name - apitherapy.

The wax has a pleasant smell, and it also looks beautiful if you give it a certain shape. In addition, it has a beneficial effect on human health by purifying the air from harmful bacteria.

How to choose the right foundation?

The quality of the material determines how successfully it will be used by bees to accumulate honey reserves. Key features of a good product:

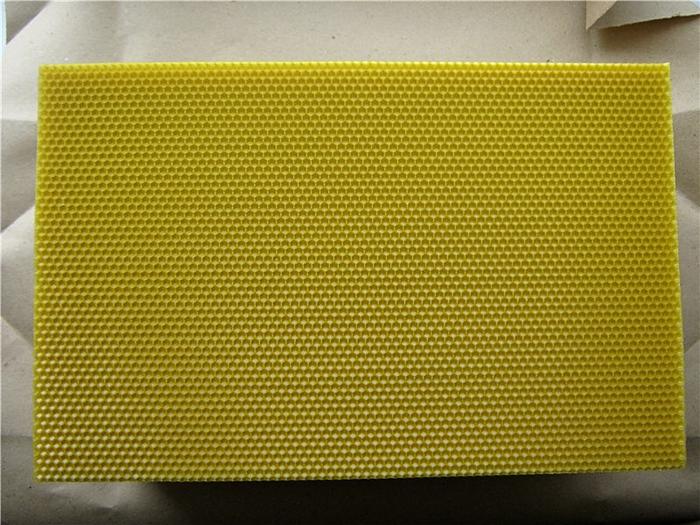

- Organoleptics. High-quality foundation is shiny and transparent to light. The presence of a grayish coating on its surface is allowed.

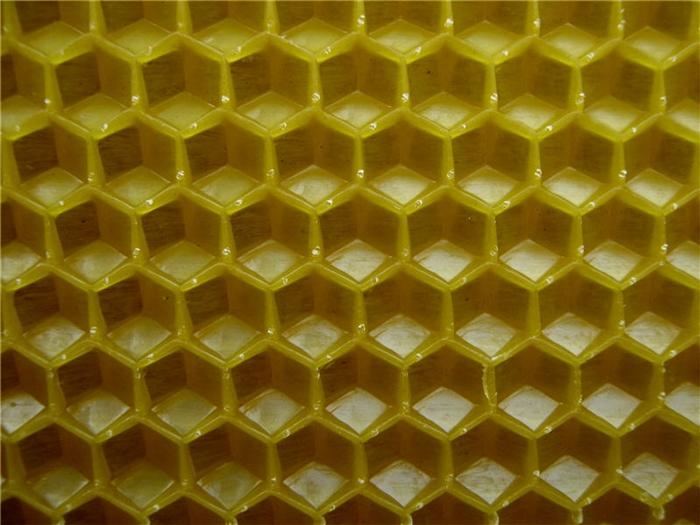

- Engraving. All its sections should be equally well translucent, and at the base form a hexagon of the correct shape.

- Cells. Identical in shape and size, their number is at least 10 for every 5.5 centimeters.

- The hardness of the wax sheet. To determine it, you need to place a wax plate in the center of your palm. If the edges of the material drop by about 30 millimeters, the product is genuine and can be purchased.

Experienced beekeepers know more tricks when it comes to buying foundation for hives. But for beginners, it is enough for now to use the specified selection criteria to purchase a quality product.

Storage Features

The method of storing foundation depends on the raw materials it is made from. It is easiest to provide optimal conditions for an artificial plastic product. It does not melt under high temperatures and does not crumble at low temperatures. It is enough to keep it in a dry place where no one can touch it. The plates should first be wrapped in film or placed in a bag so that they do not get dirty.

Natural foundation made from pure wax must be stored at above-zero temperatures, otherwise it will begin to crumble. It is folded into piles of 5-7 pieces and packed in wrapping paper or cardboard. Then it should be transferred to boxes for further storage.

Pros and cons of different types of foundation

Each type of foundation has both pros and cons. First, about the advantages of unnatural material.Among them:

- durability;

- unpretentiousness to storage conditions;

- reduction of cash costs;

- making it easier for bees to work and preserving more pollen and honey;

- absence of deformation or melting processes;

- affordability.

Disadvantages of products:

- Dyes may be used during manufacturing;

- sheets must be periodically treated with solutions to repel pests;

- a damaged sheet cannot be restored;

- Before inserting into the frame, a thin layer of wax must be applied to the wax layer;

- plastic products can negatively affect the health of bees.

The advantages of natural wax are that it does not contain unnecessary inclusions. Its composition is completely safe for bees; moreover, when created in a factory, it undergoes a preliminary coating process. Therefore, the beekeeper does not have to do this.

The downside is the fragility of the material. It is influenced by air temperature and lighting. When it is hot, the layers begin to “float”; when exposed to cold, they begin to crumble. Therefore, when choosing a product, always weigh the pros and cons of each of them.