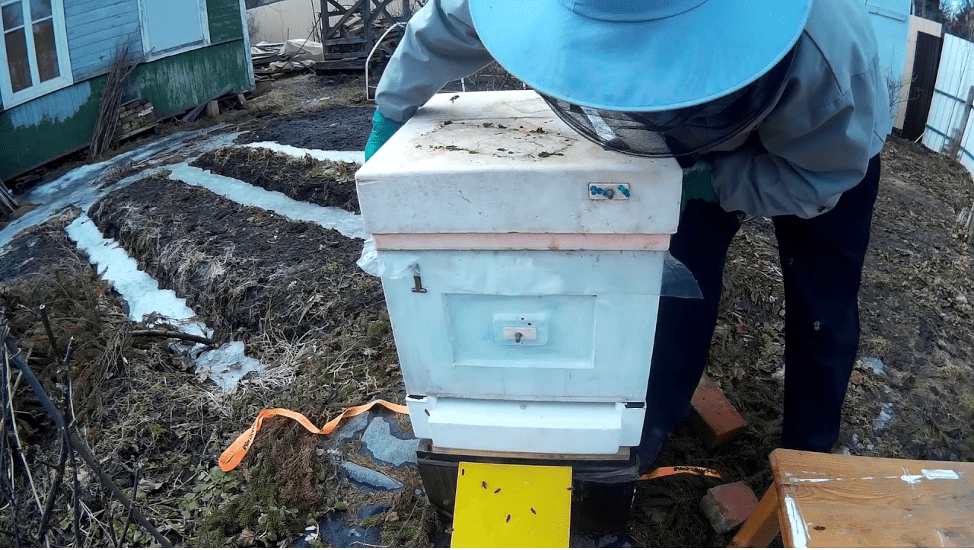

Typically, bee houses are made from different types of wood. Some structures in recent years have begun to be built from polystyrene foam or expanded polystyrene. Hives made from polyurethane foam are cheaper and weigh less. A novice beekeeper needs to become familiar with the advantages and disadvantages of such structures, the features and method of making the device at home.

Features of hives made of this material

To use such bee houses, it is necessary to take into account the structural features of buildings. The following elements must be present:

- bottom – consists of three components (bottom, tick mesh, tray);

- pallet - made of plywood, tin, plexiglass. Attention! Using a pallet, you can assess the current condition of the hive and bee family. The presence of debris and remains of dead insects (ticks and other species) indicates diseases, the presence of viruses and other diseases;

- the cover is a mandatory element, protects the bee’s home from external weather factors (and not only);

- frames - present in almost every type of hive (except for those whose design involves the independent formation of honeycombs by bees);

- movable bottom - often used in buildings that house two bee families at the same time.

Attention! Before starting work with such buildings, it is necessary to study the advantages and disadvantages of the material. Some options are not suitable for use under certain conditions (such as exposure to sunlight).

Advantages and disadvantages

The first hives made of polyurethane began to be used about 30 years ago. Positive aspects of use:

- the material is not subject to decomposition;

- mold and mildew do not appear on the surface;

- PPU provides suitable thermal insulation and sound insulation characteristics, which is especially important for regions with cold or sharply changing climates;

- The structures weigh little and are easy to care for.

Buildings made from polyurethane foam are considered environmentally friendly; they last longer than conventional wooden hives (with correct and timely care). Learn more about the advantages and disadvantages in the video.

Does the material affect the quality of honey?

The composition of polyurethane foam is considered environmentally friendly, so polyurethane foam hives are safe for bees. Peculiarities:

- studies have confirmed that the material does not emit harmful chemicals, so there is no possibility of contamination of the environment or beekeeping products. Attention! These rules apply only to high-quality polyurethane foam. Poor-quality or damaged polyurethane foam has an unpleasant chemical odor that is quite specific. Insects may react sharply and refuse the house and placement in it;

- before purchasing, you need to examine the structure for damage and the presence of foreign odors, which usually accumulate inside;

- In addition, honey absorbs foreign substances, so it is important to check the purchased structures.

Tools and materials

Such bee houses can be purchased in a store or assembled yourself. The beekeeper needs to prepare the following tools:

- ruler (metal is more suitable);

- selected material (sheet polyurethane foam);

- stationery knife;

- steel corner, liquid nails, self-tapping screws, sandpaper;

- screwdriver, hammer, circular saw.

Assembly will require some experience with hardware. It is important to follow safety rules for working with power tools.

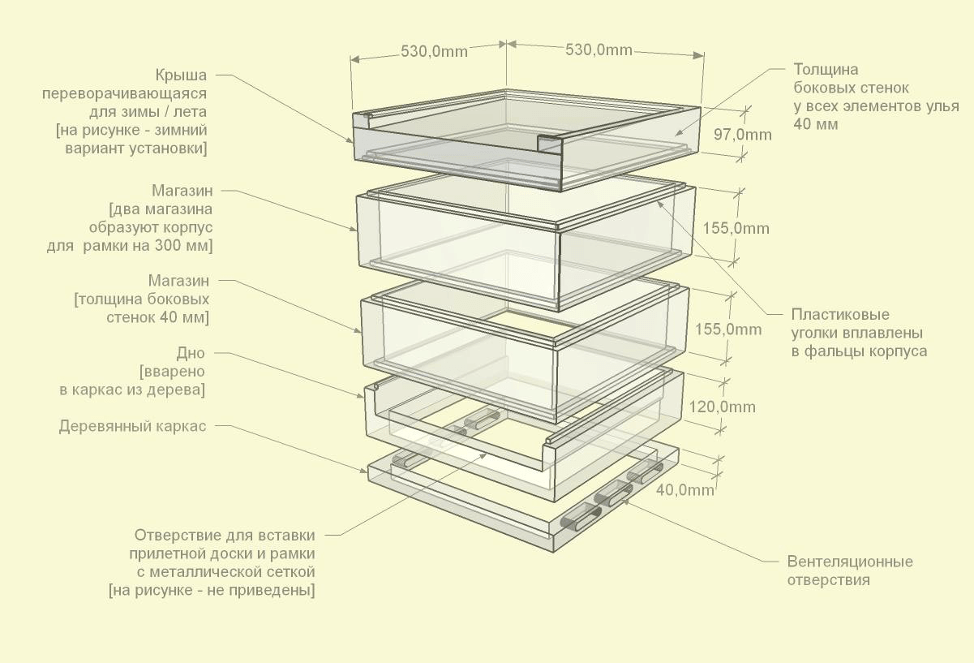

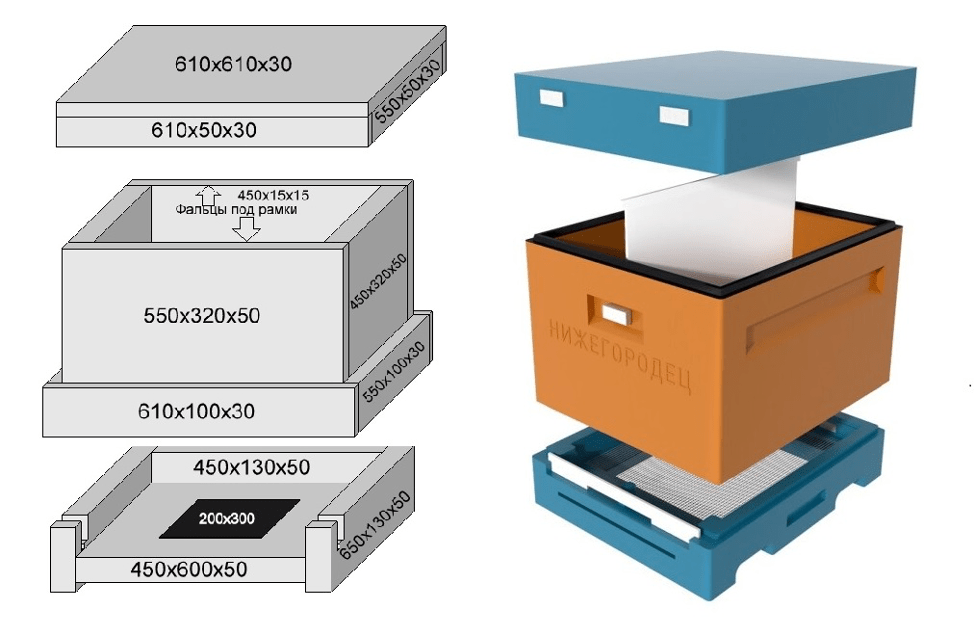

Drawings and dimensions

When assembling, the beekeeper can use ready-made drawings with dimensions or create his own. The standard version of the bee house is designed for 12 frames with dimensions of 45 cm by 45 cm. Values of other elements:

- cover – 54 cm by 45 cm, height 7 cm;

- bottom – 56 cm by 45 cm, height 10.5 cm;

- standard case – 54 cm by 45 cm, height 30 cm;

- between the side parts you need to leave a distance equal to the number of frames multiplied by 3.75 cm;

- the height of the assembled hive is the length of the frame and folds;

- 2 cm should be left between the bottom of the housing and the nesting frame.

It is recommended to first draw up a diagram on paper, installing and checking all the necessary parameters and characteristics. It is important to check the values for compatibility before starting the build. The proposed options do not always take into account the wishes and preferences of the beekeeper, so it would be a good idea to calculate your own option.

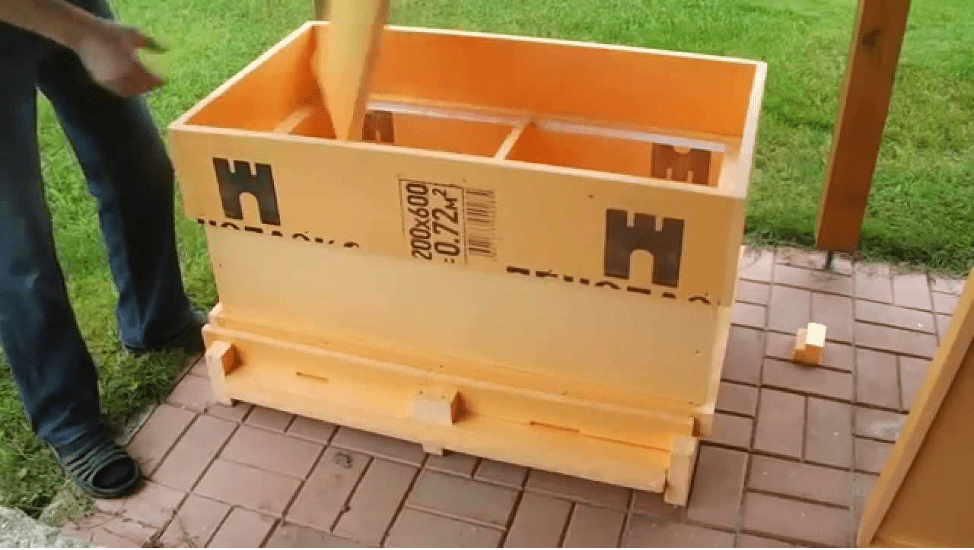

DIY making

To assemble the structure yourself, you must perform the following steps:

- apply markings to sheet material;

- cut out the necessary elements, process the edges of the parts. Attention! It is important to process the cut blocks; it is not allowed to leave jags or irregularities due to the fact that such parts can damage the wings and legs of insects. To do this you need to use sandpaper;

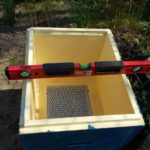

- assemble a pallet with a mesh (it is advisable to make this element from wood);

- make an insert that will help control passages in winter and summer;

- assemble the required number of cases, the edges are connected with glue;

- for greater fastening, you need to make additional wooden strapping at the top and bottom;

- ventilation holes are placed in the corners, covered with mesh (so that the bees cannot fly away).

At the last stage, the lid is assembled, which needs to be reinforced with moisture-proof material. In most cases, galvanized iron is used. The top element should protect the hive from weather conditions, rodents, and other insects. Learn more about assembling the houses in the video.

Polyurethane foam hives appeared on the market about 30 years ago.The material, although artificially created, has many advantages. The buildings are light, inexpensive, and easy to assemble yourself. You will need a small number of tools, drawings for marking parameters, and a little time.