To successfully engage in beekeeping, you need to have high-quality and comfortable hives. Today there are quite a lot of interesting options, one of which is considered to be PPU hives. They are made from polyurethane foam, which is often used to create frame structures. To facilitate the process of constructing the structure, it is recommended to use special forms for PPU hives.

Pros and cons of polyurethane foam hives

Polyurethane foam hives made from molds have certain advantages. These include the following:

- excellent thermal insulation characteristics;

- minimum weight;

- resistance to moisture;

- environmental cleanliness and absence of strong odors;

- high degree of strength;

- long period of operation;

- ease of processing and availability of repairs.

Despite the large number of advantages, such designs also have some disadvantages. The main disadvantages include the following:

- susceptibility to the influence of ultraviolet radiation;

- rapid flammability of the structure;

- lack of stability in strong winds;

- high price.

Tools and materials

To make your own PPU hives, you need to prepare the following:

- high-quality polyurethane foam - the thickness of the material should be at least 5 centimeters;

- water-based or acrylic paint;

- brush or spray bottle;

- stationery knife - the width of its blade should be more than 2 centimeters;

- tape measure or metal ruler;

- stapler with staples;

- degreaser;

- screwdriver;

- glue;

- plastic corners;

- felt-tip pen or pen;

- self-tapping screws;

- sandpaper for sanding surfaces.

Do-it-yourself polyurethane hives

It is not difficult to build a PPU. It is important to strictly follow the instructions:

- To begin with, you should buy pine boards with a thickness of at least 25 millimeters. It is important that they are well dried. The moisture content of the material should be no more than 15%.

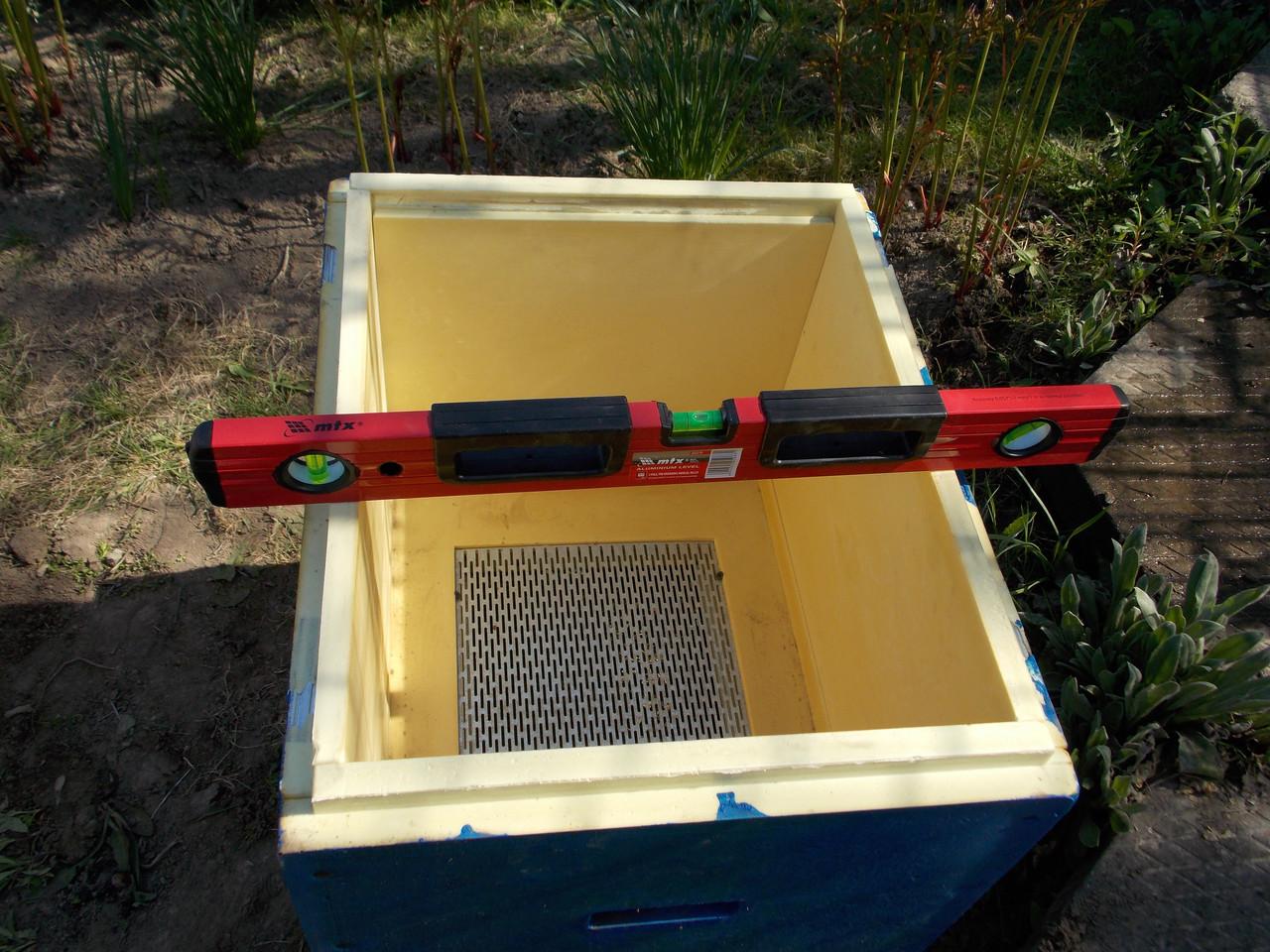

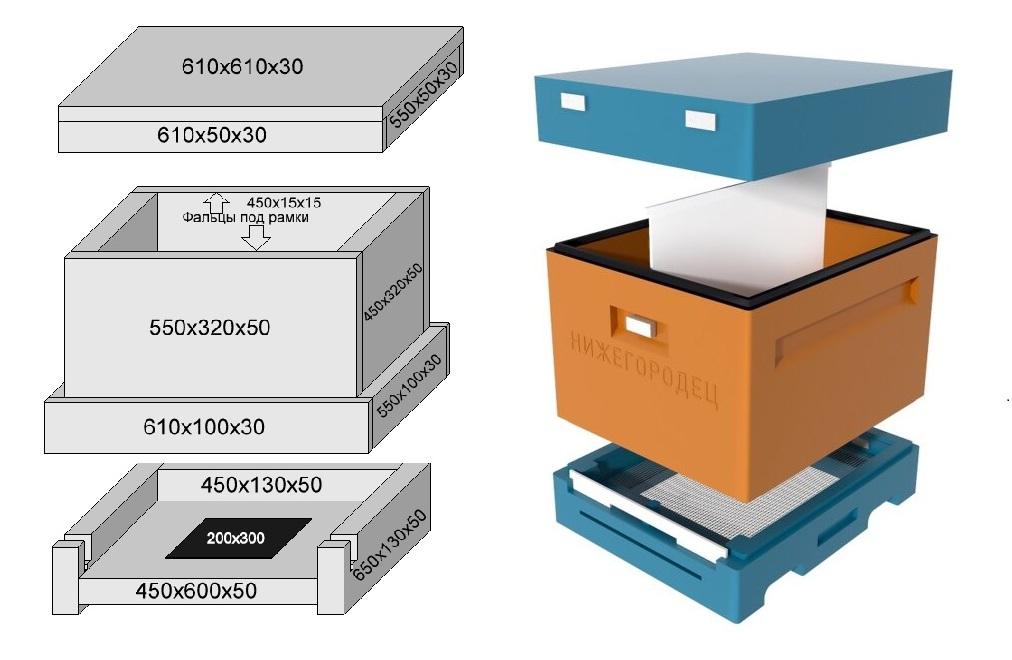

- Make a pallet 120 millimeters high from the boards. It is recommended to place a grid on the floor. You should also provide a rear door to remove debris.

- Construct the walls of the housings using rigid polyurethane foam. It should be covered with aluminum foil. All fragments should be fixed into the groove with polyurethane glue.

- Attach 2 wooden straps to the outside of the hive body.They perform the functions of the upper and lower frame. It is recommended to fix all elements with glue and screws.

- Make holes in the corners of the structure. They will help to achieve a sufficient level of ventilation. To prevent bees from flying out, it is recommended to cover the holes with mesh.

- Make a lid. To do this, you need to stuff a shield onto the harness. It is important that the lid is protected from precipitation. Therefore, it is best to make it from galvanized iron or other protective materials.

Calculation of cost and equipment

Calculating the costs of manufacturing PPU hives is not difficult. As an example, it is worth considering the cost of constructing a cover.

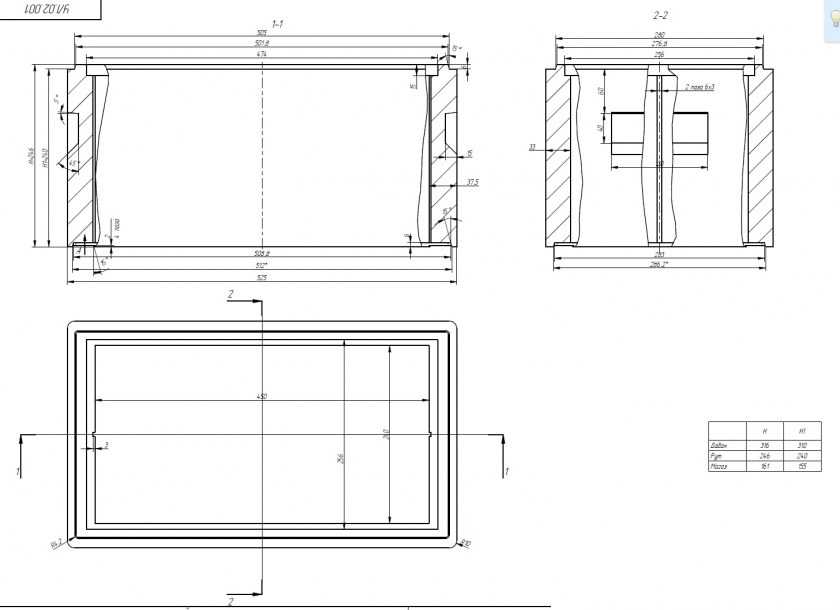

In this case, you should focus on the following dimensions:

- width – 540 millimeters;

- length – 450 millimeters;

- thickness – 70 millimeters.

The total volume of polyurethane foam with a density of 60 kilograms per 1 cubic meter is 0.01701 cubic meters. To determine the mass of polyurethane foam fragments, you need to multiply 60 by 0.01701. The result was a value of 1.0206 kilograms.

It is important to consider that each technological process is characterized by certain losses. They make up 10-20% of the total values. There is also always the threat of culling. Its reasons include the following:

- insufficient heating of the mold;

- lack of poured material;

- excess material that is poured into molds.

The total weight of the bee hive is no more than 7 kilograms. The following dimensions should be taken into account:

- Lid. The length is 540 millimeters, width – 450, height – 70. The mass of the element is 1100 grams.

- Base. Its length is 560 millimeters, width – 450, height – 105. The mass of the element is 1400 grams.

- Frame. The length of the element is 540 millimeters, width – 450, height – 300. Weight – 2800 grams.

- Shop. The length of the structure is 540 millimeters, width – 450, height – 155. Weight is 1400 grams.

To accurately determine the cost, it is worth studying the price list of companies and contacting a qualified estimator. In addition, special pouring equipment will be required to make hives. For this purpose, it is permissible to use the following types of steam generators:

- NAST-7M;

- NAST-10;

- TMS-5;

- UZK-22.

Polyurethane foam hives have a number of advantages. In addition, you can make them yourself. To obtain a reliable and durable design, it is recommended to prepare high-quality materials and strictly follow the instructions.