Every farmer can make a duck feeder with his own hands. Before the manufacturing process, you should familiarize yourself with the basic requirements for containers for feeding waterfowl. A properly designed feeder will save money on feed mixture and help maintain cleanliness in the poultry house and in the walking area.

Primary requirements

The main requirement for feeding equipment is complete safety.Food intake is an important component for waterfowl, on which the health and productivity of the animals depend. Therefore, certain requirements are imposed on feeders, regardless of whether they were chosen in a specialized store or made independently. Properly designed feeders will prevent ducks from throwing out feed from the container, which has a positive impact on the poultry farm’s budget.

If the owner includes different types of feed in the diet of poultry, then it is assumed that several containers will be installed. The height of the sides of feeders and drinkers depends on the age and size of the bird. For babies in the first month of life it should be 5 cm, up to a year - about 15 cm, for adults - at least 20 cm. At the same time, the breed of waterfowl does not matter - for Indian ducks, mulards, Peking ducks, the size requirements are the same.

In addition to size, other requirements include:

- sufficient capacity, which is determined based on the total population, the selected feeding regime and the types of feed mixtures;

- reliable fixation in the poultry house;

- free approach not only for ducks, but also for poultry farm workers;

- Possibility of quick maintenance - cleaning and drying.

It is necessary to take into account the materials from which you intend to make your own feeding equipment. First of all, they must be environmentally friendly and free of toxic impurities.

Types of feeders

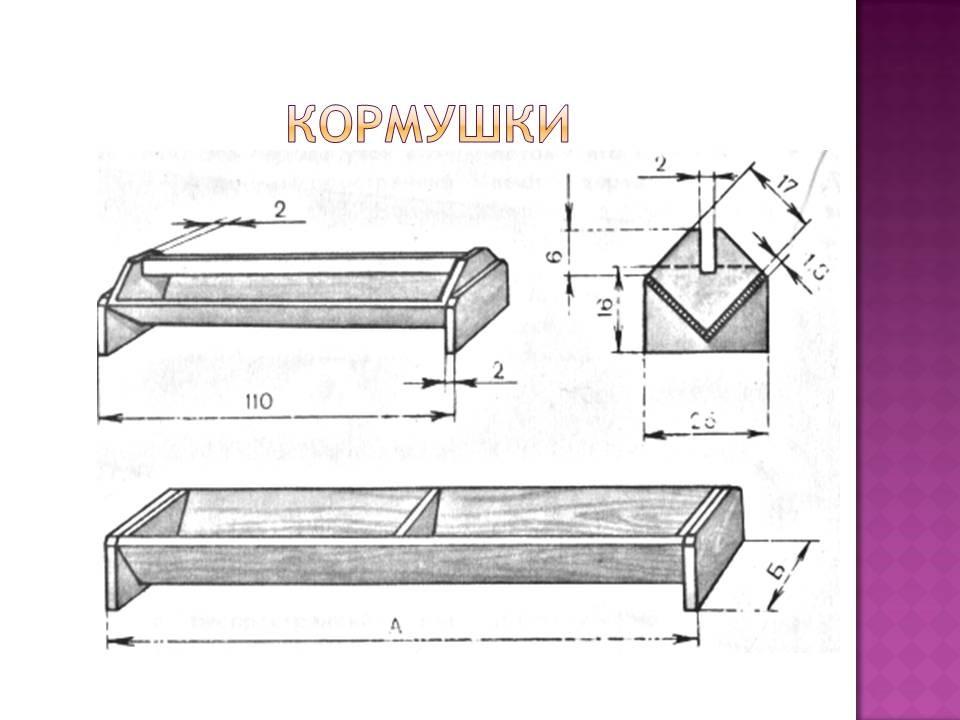

If there is a small number of waterfowl on the farm, a tray feeder is made. It is designed for ten ducks and is more suitable for dry food. The advantages of the design are fast production. The work will take no more than an hour and a half, and the materials you will need are sheets of plywood.This feeder has access from all sides. As a rule, it is fixed at a height of 20 cm from the floor. Some tray products are equipped with a locking element that is inserted into the grooves. This design significantly reduces the spread of feed.

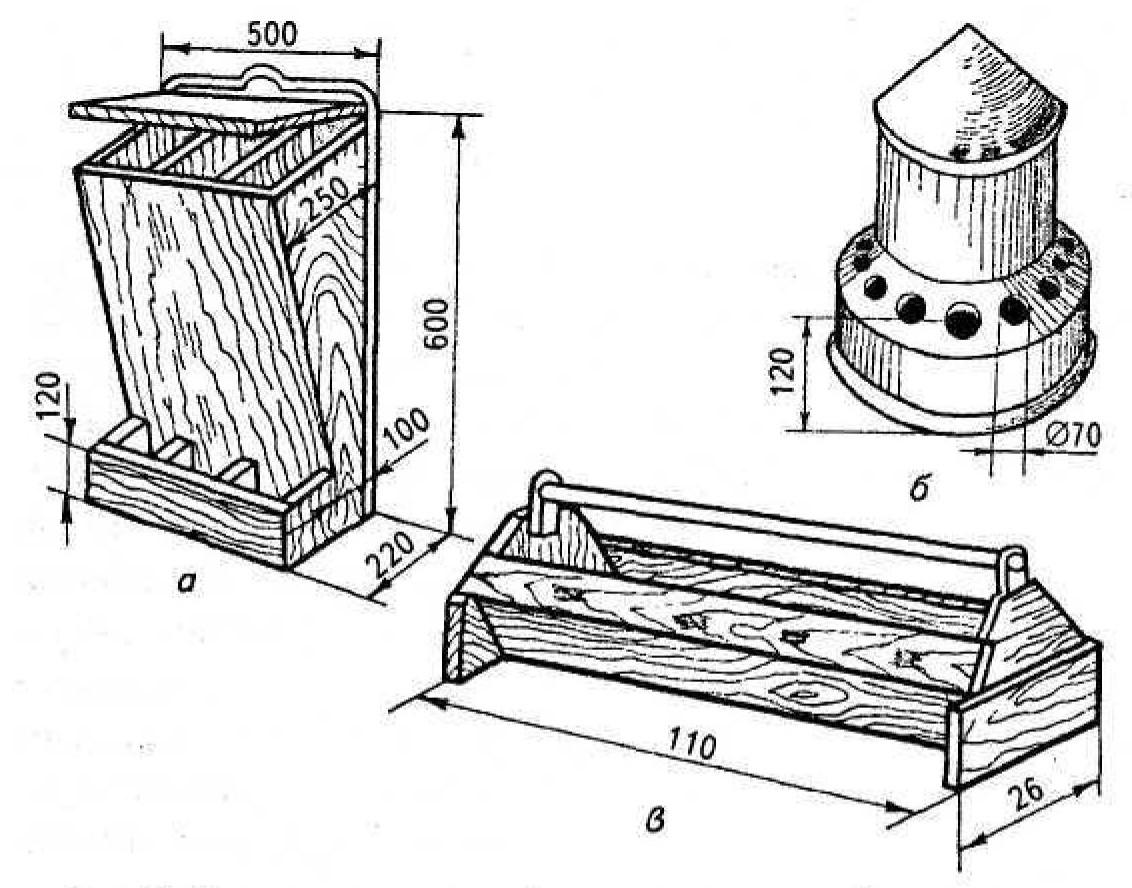

The most popular products include bunker feeding equipment. Its main advantages include the reduction of labor costs for workers. You can store a certain supply of feed mixture in the bunker, which will be enough for several days with large volumes of the structure. A similar feeder is made of wood or galvanized steel sheet. It is suitable for different types of food, including grass.

Often, owners have to quickly build a temporary structure. It is classified as an automatic feeder. Based on: a five-liter plastic water container, wire and a small round basin. It takes no more than half an hour to make, and the main advantage is that the feed is supplied automatically as the dry mixture is consumed.

Drawings and dimensions of structures

To manufacture a tray-type structure, you will need to draw up a sketch or drawing and decide in advance on the dimensions of the product.

Tray structures are easy to manufacture and are suitable for dry and mixed feed. It is important to make high sides even for small containers so that ducks cannot climb inside and scatter the food. Thanks to the shape of the feeder, it is easy to clean from food debris and can be disinfected.

A bunker-type feeder is just as easy to make, however, it will also require a preliminary sketch with dimensions.

It is important to take care of the strength and safety of the product.There should be no sharp corners, otherwise the ducks will get hurt. It is desirable that the structure be light, mobile, and dry quickly after cleaning. The material is selected depending on the diet. Wood is suitable for dry mixtures, but for wet and succulent food it is better to use galvanized steel or plastic.

What tools and materials may be needed

Every farmer will probably have the tools needed to make feed equipment:

- saw or file for working with wood, metal, plastic;

- drill;

- hammer and nails;

- pencil;

- roulette.

In addition to tools, you may need various bars, slats, metal wire, screws and self-tapping screws, and loops for fixation. As for materials, as a rule, improvised means are used. The following can help in making a feeder:

- plastic bottles, basins, small tanks, other containers of various sizes;

- plastic sewer pipes of different diameters;

- wooden boards or plywood sheets;

- metal containers or boxes;

- thin metal sheets.

Having any of these items or materials on your farm, you can quickly make a convenient feeder and place it in the poultry house.

Making feeders for ducklings with your own hands

Feeders for ducklings have special requirements. Babies are not very careful; they tend to get their paws into the food container and knock it over. Therefore, feeding equipment should be installed on the house floor and secured if it is unstable. Ducklings must have access to food from all sides. Feeders should have high sides, but small ducklings should be able to easily reach the feed mixture.

Automatic

Automatic feeders for young animals have a number of advantages. The first thing that pleases the farmer is the continuous supply of feed. In addition, the feed mixture always remains clean and does not spill out of the device. You can make automatic equipment using a five-liter plastic canister and a basin. In some cases, a bucket is used.

Make eight holes along the edges of the plastic basin at equal distances from each other. Cut off the top of the canister and make holes in the bottom, like in a basin. Cut the metal wire and fasten the basin and canister together in parts through the holes. The edges of each part of the wire must be bent so that the ducklings cannot be injured while eating. Feeders must be safe for humans when cleaning and disinfecting containers.

The resulting feeding container belongs to bunker products and is a container with a hole for supplying the feed mixture. It is easy to carry out, and no preliminary drawing is required before production.

Wooden

To make a wooden tray at home, you will need boards, slats, a hacksaw, a drill, self-tapping screws, a tape measure, and a piece of sandpaper. Initially, you will need to make a sketch of the product. Then you can start preparing the preparations. They need to be cut out and sanded. Attach the sides to the bottom with self-tapping screws. Also use self-tapping screws to attach hexagonal sidewalls. Screw the rail to the tops of the sidewalls. It is needed for convenient carrying and so that the bird cannot climb inside.

From a sewer pipe

You will need a pipe, a polyvinyl chloride tee, plugs, and files for working with metal. The pipe should be cut into 3 parts. The size of one should be 70 cm, the second – 20 cm, the third – 10 cm. Place plugs on the part of the pipe measuring 20 cm. Then you need to install the tee so that the side elbow is directed upward. The longest part must be inserted into it.

The second plug is placed on a free section of the 70-centimeter pipe, a small section is attached to the tee on the side. The resulting structure should be secured in the poultry house. This will require metal slats.

Ducklings will be able to receive food from the side of the tee. Such a feeder should be replenished with a supply of mixture once every two days. With such a device, you don’t have to worry that the ducklings will remain hungry.