Feeding troughs come in different sizes and configurations, it all depends on the age of the bird. For chicks, trays in brooders are sufficient; for the older generation, a groove-type device is built, as well as a bunker, automatic one. The main thing when raising poultry is free access to feed. You can make quail feeders with your own hands if you prepare a drawing and follow the manufacturing technology.

Requirements for feeders

To effectively keep quails, you need to take care not only of lighting, temperature, food, but also of equipment.

A good feeder meets the following requirements:

- Safe for poultry health. Feeding equipment must not emit toxic substances when used. They should be easy to clean, strong and durable. It is best if the feeders are made of plastic, ceramics, wood, stainless steel, galvanized sheet. Copper is not suitable here.

- Correspond to the dimensions of the cage, the number of quails and the volume of food. It is optimal when the box is filled to 2/3 of the total volume, otherwise the food will be outside, on the floor.

- Have sufficient side height. If they are very low, then the food will get inside the cage and mix with the droppings.

- Stable during operation. The bird should not be injured while eating feed; regardless of the type, the structure must be well installed.

- The design must be reliable and easy to maintain. To attach the feeder, you should use hooks instead of screws; they make it possible to easily remove the equipment for cleaning.

Important! Total number of quails per 1 sq. m cage is 15 quails, the calculation for normal feeding is 5-9 cm per head. When using an external feeder, there must be a minimum of 1.1cm of tray length per bird.

Types of designs

When choosing a feeder, it is worth considering that quails are characterized by scattering of food and its contamination. There is a fairly large assortment of devices for feeding poultry on the market, depending on the type of loading they are:

- Tray. This is the simplest version of the feeder, which is more intended for feeding quails up to two weeks old.They can be installed both inside the cage and outside.

- Grooved. This type of feeder has a universal purpose, suitable for both the younger generation and adults. Its advantage is that it can accommodate several types of food inside. You can prevent its scattering by quails during feeding by creating a front of 30-50 mm. The location of such a feeder is outside the cage.

- Bunkers. This variety is relevant for feeding adults. It is often installed outside, but there are options for placement inside the cage. The peculiarity of this device is that the food used should only be dry. You can fill the feeder once every few days. As it is consumed, it will automatically flow into the container.

- Automatic. In fact, this is also a bunker device, but in an improved design. The food here is supplied to the quails without human intervention. This device has a timer that allows you to adjust the feed supply to the birds. There is also a dispenser for determining portions. This is an effective option for equipping poultry houses on a large scale. It's difficult to do it yourself.

Depending on the design features of the feeder, there are the following types:

- Suspended and floor. If the bird is kept free, then it is worth choosing floor-mounted equipment. Hanging devices are mounted outside the cage and protect food from debris and dirt.

- Cellular and grooved. The first option of a feeding device is relevant for young animals; the chicks have enough space and eliminate crowding around the platform with food. Grooved models are excellent for adult specimens; each requires 17 cm of feeding front.

- Buffer and open.The first devices have a dispenser that allows you to dispense feed in equal volumes. In the second models, grain is added every day.

How to make a quail feeder with your own hands

At home, you can make devices for feeding poultry of almost any variety. The simpler the device, the faster and easier it is to make it from available materials.

Hopper made from a plastic bottle

To make a feeder, you need to prepare plastic containers (2 pieces), screws and a drill. The algorithm for performing the work is as follows:

- Cut off the top and bottom parts of the bottle, 8-10 cm away from the neck, and drill holes with a diameter of 2 cm in a circle.

- Insert the workpiece into the tray with the holes facing down.

- Secure with self-tapping screws.

- Pour in food.

To speed up production, you need to look at the drawings and select the appropriate container.

Grooved hinged

To create a wall-mounted model, one galvanized sheet is enough. Additional materials include nails and plywood.

Manufacturing instructions:

- Cut out 2 sides from a sheet of plywood.

- Draw a bend line on the galvanized sheet of metal according to the dimensions of the sides. Bend the sheet.

- Install the sides, securing them with nails/screws.

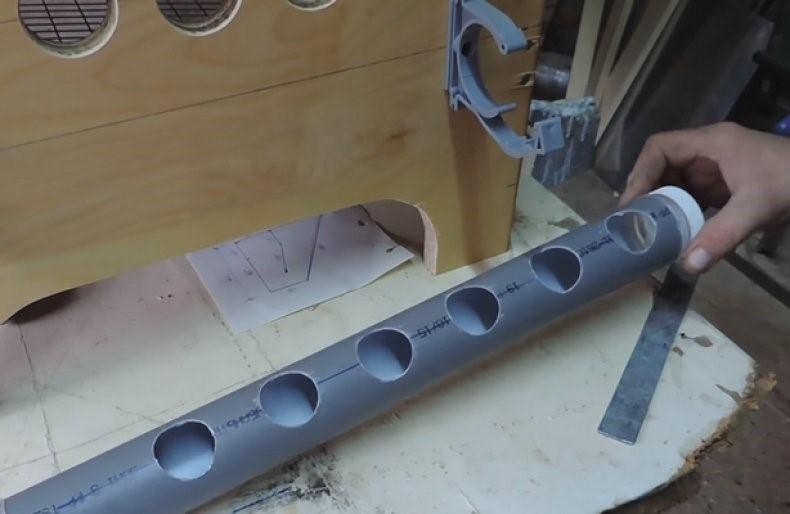

Pipe tray

Making a feeder from a pipe with your own hands is as easy as making one from a plastic container. The manufacturing process consists of the following stages:

- Prepare sewer pipes of larger and smaller diameters.

- Drill as many holes in the workpiece as there are heads available. The hole in the center should be the same diameter as the smaller plastic feed pipe.

- Insert plugs on both sides.

- Secure the feeder in the cage.

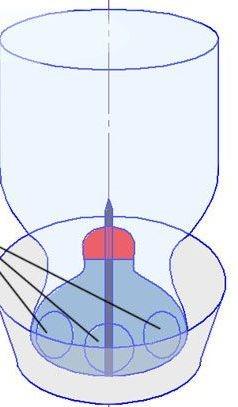

Automatic feeder

An automatic feeder is a complex device, but if you wish, you can make it yourself. Necessary:

- Remove the bottom from the tank from the cooler.

- Install plywood/tin plates inside.

- Connect the neck of the tank to the nozzle of an electric meat grinder.

- Make a side hole in the plastic funnel.

- Fix the funnel on the meat grinder.

- Place the pipe.

- Place the hemisphere in the tray.

- Connect the meat grinder to the dispenser using the power cable.

Video on how to make an automatic feeder for poultry with your own hands:

Installing feeders in the cage

Devices made of PVC pipe are mounted on the front side of the cage, at an angle. If there is no bunker, then they are mounted in parallel. The same principle applies to plastic containers. The profile tray device is simply installed into the cage. DIY quail feeders are made from scrap materials. The main thing is to follow the manufacturing technology and count on the number of heads.