Grain storage is a complex effort aimed at preserving reserves. Proper organization and storage allows you to maintain the quality of raw materials and minimize losses. Let's consider where and how grain is stored, what methods are used, and the shelf life of grain stocks. What problems can you encounter during storage and how to avoid them.

Where is grain stored?

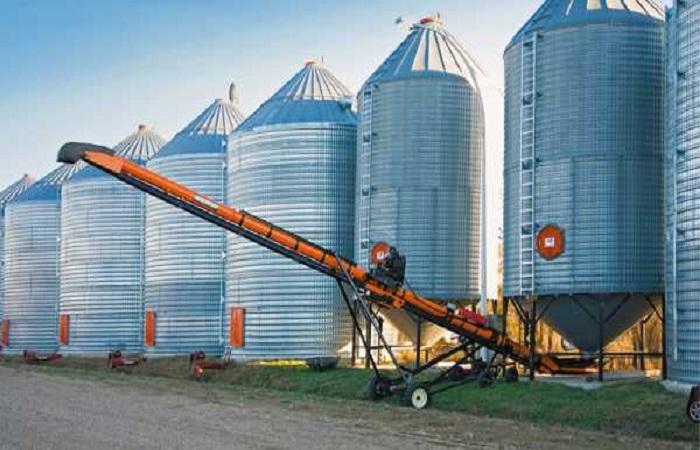

The success of storage depends on how well the storage facilities and the grain itself are prepared, and how the storage regime is followed. The grain mass is stored in warehouses (elevators). Before placing products there, the room must be disinfected.Preparation is carried out in different ways: wet, gas, aerosol. All premises, equipment, containers and transport must be completely disinfected.

Grain preparation includes drying, cleaning the grain from weed seeds, soil and other things, after which it is cooled to at least 12-15 ° C.

Methods

There are several ways to store grain crops. Some of them are used more often, others less often. It all depends on the type of storage and its capabilities, on the volume of raw materials stored for storage. The storage type can be closed or open.

Closed is the placement of products in concrete warehouses and metal containers. Open involves placement in heaps and trenches on the street with mandatory shelter from rain and sun. This is how fresh grain from the current harvest is stored; the closed method is used to preserve stocks for a long time.

in bulk

Bulk storage is the main and effective way of long-term storage of grain stocks at receiving, sorting and cleaning points. They warehouse and store grain by simply pouring it into piles on the floor of the warehouse. The method has many advantages over others:

- storage area is used rationally;

- rational use of granary resources;

- convenient to load products for transportation;

- allows you to effectively combat pests;

- convenient to monitor and check the condition of products in storage;

- saving on packaging costs.

The bulk method is practiced in covered warehouses and open areas for temporary storage. The grain is poured into containers or stored in piles, which are surrounded by a fence and covered with dense material that does not allow water to pass through. Seed material is not stored in bulk.

Dry method

The drying method, complete or partial, is used on an industrial scale for long-term storage in granaries. It is based on the fact that when moisture is extracted from grains, pathogens located on the surface cannot develop. The possibility of developing diseases is sharply reduced; such grain must be protected only from being eaten by rodents and insects.

Dehydration is carried out in two ways: with the help of heat and without its use. The greatest profitability is shown by the method in which the grain is poured into containers where it is treated with air and heat.

Oxygen-free

The method is used mainly where the quality of the stored raw materials is of great importance. Enterprises use it because in the absence of oxygen in the grain, almost all pathogens and insects die. The oxygen-free method does not have a negative impact on the quality of raw materials; all nutrients are preserved. The method is used in flour mills and bakeries.

Cooled

This method is popular in farming operations or small warehouses. This mode is convenient if it is not possible to quickly dry the grain, but you can save it in a cool state.

The technology is economical and is characterized by small product losses.The principle of the cooled method is similar to the drying method and lies in the fact that at low positive temperatures, as well as when exposed to heat, microorganisms stop their development. To preserve cooled grain in warehouses, a temperature of 5-10 ºС is artificially created and maintained.

Typically, supply and exhaust ventilation is used for this purpose; in summer the system operates at night, in other periods of the year - around the clock. Sometimes the grain is mixed on conveyor belts and cooled by fans. But this method is expensive, so it is not as popular as the usual one.

In bags

The packaging contains seeds of elite varieties of cereals or the first harvest collected from a new variety of cereals. Conventional planting material is often stored in bulk. The bags also store grain of expensive varieties with a thin-walled shell. Fabric, polypropylene or nylon bags that are resistant to moisture and damage are used. Bags with contents are stacked on pallets made of boards, the height of the stack is no more than 10-12 tiers.

In ears

The method of harvesting and storing crops in ears involves cutting the ears of corn in the field and forming them into ventilated bales. They are then transported to a ventilated warehouse where they are placed on pallets. The bales are cooled and left to dry and ripen. When cooled, the spikelets are stored until threshing.

Shelf life

Wheat food grain can be stored for up to 4-6 years. Seeds of winter crops are stored for 13-14 months, spring varieties - 7-9 months. Grain from seed banks can be stored for more than 2 years.

Possible problems

When storing grain, you may encounter dampness due to high humidity.Wet raw materials will begin to warm up and rot; humidity and heat provoke the rapid development of rot, mold and other diseases that spoil grain products. To prevent this, you need to monitor the temperature and humidity inside the heap or container, ventilate and cool the room.

Pests damaging stock are also a common problem. Weevils, moths, mites, and moths multiply during the warm season. In winter, reproduction stops, but product spoilage continues.

Measures to control pests of stocks: insecticidal treatment of crops before harvesting, disinfection of warehouses before loading crops into them, sifting grain through sieves to remove small insects, monitoring and maintaining optimal temperature and humidity in the warehouse.

External factors have a huge impact on the success of storing grain products in warehouses: temperature, humidity, lighting, oxygen level. If you organize all processes correctly, you can significantly reduce product losses, which are inevitable when conservation rules are violated. Properly stored grain does not cause losses; its appearance and quality remain high, no matter how long it is stored.