When planting crops over large areas, special auxiliary equipment is required. An attachment to a walk-behind tractor or a manual planter for garlic will help you quickly and efficiently sow crops in large areas or in the field.

- Appearance and principle of operation of the device

- Planting garlic with a garlic planter

- Main types of planters

- How to choose a planter for your site?

- Operating principle

- Seeding type

- Productivity and number of rows

- Weight and dimensions

- Popular models on the market

- How to do it yourself?

- Reviews from the network

You can choose a suitable model in the store, but a DIY garlic seeder will be no less functional.

Appearance and principle of operation of the device

The manual garlic planter is designed to make the planting process easier, save time and improve quality by evenly distributing the cloves throughout the area.

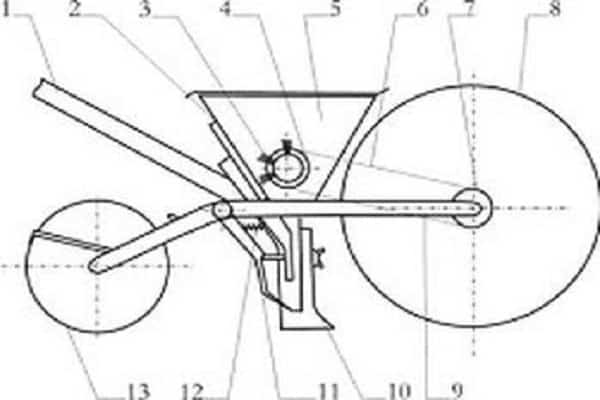

The basis of the equipment is a metal frame with long handles, on which a sprocket, chain, gearbox and container for laying seed are attached. The planter is equipped with iron discs that distribute the seeds evenly along the entire length of the furrow, and mounted blades that cover the tines with soil.

In the process of moving from the wheel on which the sprocket is attached, the chain through the gearbox feeds the mechanism for removing the garlic cloves from the container. Using a coulter, a furrow 15-20 cm deep is prepared. And through the pipe, the tine falls to the surface of the earth. Some models are equipped with water tanks, from which watering is carried out simultaneously with planting.

The equipment can have 1 or 2 wheels. In addition, 1 or more landing structures.

Planting garlic with a garlic planter

Features of using a garlic planter depend on the feeding method, the presence of a calibration mechanism, and the number of simultaneous sowing devices.

Before planting, the hand seeder is adjusted to the desired furrow depth. Then the distances between them are selected. The slices are poured into the container. If there is a tank, it is filled with plain water or with the addition of fertilizer.

From the very edge of the area, lightly pressing on the handles, they begin to push the device at low speed to the very end. During the process, the presence of seeds and the functionality of the seeder are monitored.

Main types of planters

The garlic planter can be manual or made as an attachment for a tractor or walk-behind tractor.

Manual ones cost less and do not require fuel, but in the process it will be necessary to exert greater effort to press the opener into the ground and move it forward. For the unit to operate, the soil must be soft and loose.

The attachments on the walk-behind tractor are heavy and have devices for planting several rows at the same time. They cling through special fasteners and adapters to the rear of the machine. With different power capabilities of tractors, seeders are used that differ in weight and number of rows.

Four-row planters are capable of accurately and quickly sowing garlic cloves over large areas. They are equipped with a device for calibrating seeds and can effectively perform the assigned tasks on any soil.

Each of the devices is quite good; the best models are selected solely from the individual preferences of the farmer.

How to choose a planter for your site?

When choosing a manual seeder or tractor attachment, you need to consider several factors:

- the ability to make furrows of the required depth;

- number of rows;

- seed feeding mechanism and their size.

Operating principle

Small plots of land can be cultivated manually. To sow fields on a production scale, you will need an attachment for a walk-behind tractor.

The operating principle of all seeders is the same. First, a furrow is made, a clove of garlic is placed in it and sprinkled with earth. If watering is required simultaneously with planting, the model must have a special container for water or fertilizer solution.

Seeding type

Sowing may differ in the depth of the furrow and the distance between them. If you need to sow garlic seeds, a planting depth of 60-80 mm is recommended, and the cloves should be deepened to 15-20 cm.

An important factor for ensuring uniform planting is the mechanism for feeding and selecting seed. If the conveyor is equipped with medium or large bowls, the bulbs will be sown several times in one place. And the small cells of the feeding mechanism are not suitable for garlic cloves. There will be gaps during capture. Therefore, it is better to pay attention to models in which seeds are supplied directly from the container by opening the blade through the gearbox axis.

Productivity and number of rows

The larger the area, the more rows the unit must sow at the same time, which also means a bowl for the largest volume of seeds.

On a garden scale, it is better to use a manual single-row model, a seeder for garlic bulbs the field must have at least 4 sowing devices. Interesting are the nozzles in which the containers are removable. This allows you to change the planting row.

A hand seeder can be equipped with a wheel or two. At the same time, the second one is more effective, as it maintains balance. Attachments can have 2 main load-bearing wheels and several intermediate ones.

Weight and dimensions

All parts of the seeders are made of durable and thick metal. The more massive the structure, the greater the weight and size.

The dimensions of manual garlic planters are small. The weight of the units is up to 10 kg, but working with them will require more time and physical effort.

The large weight of tractor attachments is due to the size of the device and the need to press with great force on the surface of the earth in order to make a furrow.

Popular models on the market

Domestic manufacturers have developed a number of seeders that meet the needs of any farmer. It’s convenient that there are no problems finding and purchasing the necessary spare parts at an affordable price. Let's look at the most popular models:

- SMK-3 VPS27/1-10/4 is a manual three-row seeder. This model has the following parameters: distance between rows - 12 cm, the ability to install attachments for other crops, furrow depth - from 1 to 3 cm, weight - 3 kg.

- The ChS-1 single-row seeder is designed for installation on a 6-hp walk-behind tractor. pp., it is possible to calibrate seeds (15-25 mm) with planting increments of 11, 12.5, 14 cm, container capacity - 10 l, furrow depth - 6-8 cm, weight - 20 kg.

- The two-row model ChS-2 is manufactured as an attachment for any 6-hp walk-behind tractor. With. The width between the rows is adjusted within 20-40 cm, the sowing depth is 6-8 cm. There is a calibration device and large containers for seeds. The weight of the entire structure is 44 kg.

- The four-row ChS-4 is equipped with a capacity of 10 liters, the planting depth is 8-10 cm with a seed ejection distance of 11, 12.5, 14 cm. The row spacing is selected within the range of 20-53 cm. The weight of the entire structure is 73 kg.

- The attachment for the ProTek TM walk-behind tractor is a collapsible model, so the number of simultaneously planted rows can be changed. Seed calibration is carried out within the range of 2-16 mm. The container volume is 5 liters. Loosening depth is 1-10 cm. You can change the frequency of opening the gutter. Product weight - 60 kg.

How to do it yourself?

Buying a suitable seeder is the easiest way, but it will require a lot of money. There is nothing cheaper at home than making a planter with your own hands, which will be perfect for use in your garden.

If a person is familiar with the structure and operating principle of seeders, the manufacturing process will not be difficult. The main thing is to find all the necessary components and assemble them.

For production you will need:

- container for seeds;

- a shaft that connects the feed mechanism to the gearbox;

- brushes or tape with cups for capturing and feeding cloves;

- required number of suitable wheels;

- opener for creating furrows and 2 blades for filling them with earth;

- a frame with handles on which all equipment will be attached.

In order for planting to be carried out evenly, the container must have a double bottom. A hole is made in it into which a ribbon with cups is inserted. If feeding will be done by dropping a tooth from the tube at the bottom of the container, it is equipped with a movable plate, connecting it to the shaft.

A sprocket is installed in the lower front part immediately next to the wheel. A simple bicycle chain is put on it and connected to the gearbox.

At the rear of the frame, a coulter is welded or bolted. Behind, the blades for falling asleep are installed at a slight angle to each other at a short distance.

A self-made seeder is in no way inferior in functionality to purchased models. Even in some cases it surpasses them, since it is made to suit the needs of the farmer.

Reviews from the network

Anatoly, 48 years old, Pskov:

“Before using a homemade seeder, we had to plant garlic and onions by hand, which took a lot of time. The process itself was tiring: first make the furrows, then scatter the seeds, cover them. With the planter, all work is done quickly and efficiently, you just need to put in a little effort.”

Vasily, 53 years old, Samara:

“I made the garlic planter myself.At first I made many mistakes: I placed the seed dropout chute high (they jumped out of the furrow), did not calculate the required loosening depth and did not think through the backfilling mechanism. In addition, he simply moved a small amount of earth with the wheel. Then I looked at several ready-made schemes of other farmers and corrected the shortcomings. Now I’m enjoying the sowing work and the rich harvest.”

Nikolay, 54 years old, Stavropol:

“I made my own attachment for a walk-behind tractor with 5 rows. Comfortable. Maintained a distance of 30 cm between the coulters. Instead of containers, I put old plastic six-liter bottles upside down, attached PVC tubes to them and ran a tape with glued halves of balloons (I saw them in a children's store, but did not understand their direct purpose). I welded the frame from a corner and a pipe, the weight was great, enough to bury a plow.”