It’s not difficult to make a disk hiller for a walk-behind tractor with your own hands. This is a multifunctional device that helps change the condition of the soil, make furrows and form ridges during hilling potatoes or other vegetable crops.

Variety of choices

A walk-behind tractor or cultivator will help make planting and caring for potatoes easier. When working in the garden or vegetable garden, they are considered indispensable assistants. An integral part of the walk-behind tractor is the plow. It can be revolving and disk. An additional accessory to the technique is a hiller, which can be of several types.

It will not be possible to immediately determine which hiller is better.The choice of hillers is influenced by many factors, including soil characteristics, the size of the land plot, and the financial part of the issue plays not the least role. Therefore, in order to make the right choice, you need to get acquainted with the description of the most common hillers for walk-behind tractors:

- Hillers that do not require independent adjustment of the width between the metal wings. The furrow for all crops will be the same distance, which is not very convenient. These types of structures are convenient to use for a motor cultivator weighing no more than 30 kg. In addition, the device’s stands are thin and not suitable for cultivating hard soil.

- Equipment that involves changing the width between the wings, so the distance between the furrows can be made different. You can also use two units at the same time on one hitch. It is recommended to install it on a walk-behind tractor weighing more than 30 kg.

- The most popular type is the single-row hiller. The device is designed to work with light soil pre-treated with a cultivator. If a single-row plow is used, the lugs are installed close to each other. This is necessary because hilling is carried out one row at a time. There is a more modern two-row hiller for a walk-behind tractor.

- Another device for hilling vegetables is the Dutch hiller. It allows you to adjust the wings not only horizontally, but also vertically.

- The active hiller (rotary) of the propeller version is easy to use. It has a completely different operating principle. The rotary hiller has rotors with parallel teeth instead of wheels. The device can be installed on a walk-behind tractor and cultivator with two forward gears.Propellers mounted on the crossbar are convenient for crushing and loosening the soil, removing weeds with roots and hilling plants.

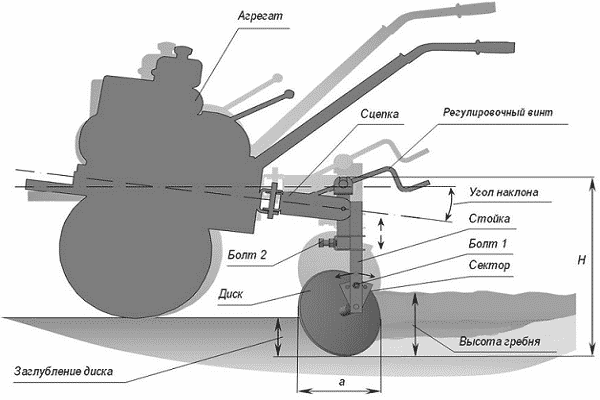

- The best, judging by the reviews of owners of walk-behind tractors with an additional device, is considered to be a disk hiller for a walk-behind tractor. It consists of a T-shaped leader, screw adjusters, two stands and two disks. The working elements do not look like wings, but like disks. You can change not only the width, but also the angle of inclination. The result is ridges on the treated area of the required height and width.

Before you start working on your plot of land, you need to know about the settings of the selected attachment. Improper use or installation of equipment may result in crop loss and other adverse results.

The preparatory stage is to cultivate the desired area, it is better to loosen the soil. At the same time, you can apply organic or mineral fertilizers. The looser the soil, the easier it will be to make furrows.

Before planting potatoes with a walk-behind tractor, you need to set marks at a distance of about 65 cm. Then, using a walk-behind tractor with a hiller, make furrows and lay out the planting material. After this, the wheels are changed to rubberized ones, and the wings of the potato hiller to the walk-behind tractor are set to the maximum width. The walk-behind tractor is installed between the rows and the plow is driven along the furrow, covering the planted potatoes.

How to make a hiller?

Hiller for potatoes, made for a walk-behind tractor with your own hands, will be no different in functionality from a unit produced in production. It's easy to do. To work, you will need a welding machine, a grinder and a metal sheet no more than 3 mm thick. It is imperative to take into account the attachments designed for the walk-behind tractor or cultivator.The cultivator has less power than the walk-behind tractor.

For a lister-type hiller on a cultivator, you will need metal 2 mm thick, from which the working material - half-wings - will be cut. After the parts are cut out, they need to be bent to the desired radius. Subsequently, the parts are welded at the fixation points. The edges are processed with a grinder.

The distance between the two half-wings is fixed with a steel crossbar. A metal pipe with several holes is welded on the inside of the device, which allows you to install the required recess in the soil. Another pipe is bolted to the stand, which goes to the walk-behind tractor.

You can also make disc hillers for a walk-behind tractor with your own hands. Making them is a little more difficult than the lister type, but if you have the drawings at hand you can try.

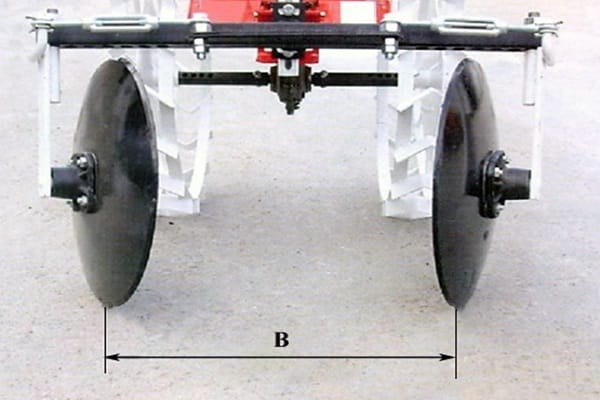

To make a homemade disk hiller, you will need to purchase two concave disks (discs from an old seeder will do). You can cut metal plates 2 mm wide yourself. The diameter of the disc hiller circles must be at least 40 cm. You will also need two stands and lanyards, and a leash in the shape of the letter “T”.

At the required distance, the disks are fixed at an angle on the stand using adjustable adapters using welding or bolts. Lanyards make it possible to adjust the disks vertically. When making a hiller yourself, you must ensure that the discs are installed symmetrically. Otherwise, the walk-behind tractor will skid to the side. The edges of the discs are processed with a grinder and sharpened well. The finished plow is attached to the beam, and then, using a T-shaped device, attached to the walk-behind tractor itself.

A self-made disk hiller has many advantages.Anyone can make it, you just need to find available drawings and diagrams (you can find them in special gardening magazines or on the Internet). Do-it-yourself potato hillers will require little expense, but the efficiency is no different from a ready-made device.

How to set up a disk hiller?

Adjusting the equipment involves its correct direction relative to the furrow. It must be parallel to the beds on the land with a certain angle of inclination and width of the furrow. Good setup of equipment will allow you to avoid mistakes and achieve good results during work.

To set the angle, the unit has a special screw adjustment, which tilts the entire device relative to the walk-behind tractor. The depth of the furrow depends on the part being adjusted. In addition, adjustment is carried out when installing the hiller to the walk-behind tractor. This is done using holes made in the rack for fasteners. If moving hillers are installed, you can adjust the width and height of the ridge produced.

The disc hiller is of higher quality than the plow, despite the fact that it takes more time to cultivate the land. The work is carried out not on two furrows, as is the case with a two-row hiller, but on one.

The disk weeder is easy to set up. The lower points of the disks are spread apart by approximately 40–70 cm (it all depends on the distance between the rows; the recommended width between furrows for potatoes is 60–65 cm). When setting up the equipment, you need to remember about the angle of inclination and be sure to ensure that the disks are symmetrical to each other.

The walk-behind tractor is placed in the furrows so that the furrow to be processed is between the working discs. They are carried out exactly along the row spacings, without affecting the vegetable crop.The discs pick up the soil, forming a ridge, and at the same time loosen and crush large clods of soil.

During the entire period of growing potatoes, three hillings of potatoes are done. The first time the work is carried out when the height of the bushes is approximately 16 cm, the second time when their height is approximately 23 cm and the last time after flowering has completed.