Turkey meat is confidently gaining ground over the most common chicken meat today. Before reaching the consumer's table, the turkey must be well fed. Experienced farmers know that the rapid weight gain of poultry depends not only on a balanced feed supply, but also on how correctly the feeder is selected for adult turkeys and growing livestock.

- General requirements for turkey feeders

- Existing varieties

- Wooden

- Plastic

- Metal

- Made from mesh or metal rods

- Sectional

- This type of feeder is most often used for growing poultry populations.This is explained by the fact that, in addition to the main diet, the chicks need to be offered additional complementary foods; accordingly, a separate section is required for different foods and additives.

- Bunker (automatic)

- Necessary tools for DIY

- The set of tools that will be required to make a turkey feeder directly depends on what material will be used in the work. As a rule, the standard list includes:

- How to make a turkey feeder with your own hands

- From a plastic pipe or bottle

- Manufacturing of pipe system

- Making a feeder from a plastic bottle

- Made of wood

- Hopper feeder

General requirements for turkey feeders

The choice of equipment for feeding turkeys depends on a number of factors:

- number of birds in the house;

- age of the livestock;

- size of the poultry house or aviary;

- feed components of poultry diet.

If a capacious poultry house or farm requires the installation of bunker or tube feeders, which make it possible to provide food for a large number of birds, then in a small household you can get by with simple trays.

Young birds require a separate structure for feeding. This is due to the fact that turkey poults require less feed than adult birds. In addition, growing livestock need additional feeding and additives in the form of grass and lime.

Existing varieties

Equally important is what materials the food storage area is made of. Today you can find devices made from a wide variety of materials, but the most commonly used are:

- tree;

- plastic;

- metal.

Wooden

It cannot be said that any material has an obvious advantage.For example, wooden trays are suitable exclusively for dry food, since this material is difficult to disinfect due to its porous-fibrous structure.

Important! Wooden trays require careful hygienic control. Violation of sanitary standards can lead to spoilage of grain and, as a result, chronic diseases or loss of poultry stock.

Plastic

A plastic feeder is a safe, easy-to-clean feeding device for turkeys. One of the disadvantages is the relative lightness of the design.

Therefore, preference should be given to feeders that are made of heavy plastic or are structurally weighted to prevent the turkeys from tipping over under the pressure of the heavy weight.

A device for feeding feed from plastic pipes is most often used in farms that produce poultry meat on an industrial scale. Among the advantages are the following:

- the ability to quickly feed the maximum number of individuals;

- the design does not require much space;

- relatively low cost and simplicity (even beginners can install a pipe feeding system).

Important! To prevent turkeys from fighting for food, there should be a lot of holes. In this case, the frequency of their location should be equal to the bird's step.

Metal

Metal structures for feeding turkeys can be of a wide variety of shapes and volumes. In terms of hygiene, they are more practical than wooden ones and can last quite a long time.However, before you put food in them, you need to make sure that there are no sharp corners or cutting edges that could injure the bird.

Made from mesh or metal rods

A mesh feeder is a rectangular piece of chain-link mesh, rolled into a cylinder, with a wooden bottom or tray. This device is filled with fresh grass, which turkeys need as a source of vitamins and fiber. If you make this device yourself, you need to make sure that the sharp ends of the wire are bent and do not injure the bird.

Sectional

This type of feeder is most often used for growing poultry populations. This is explained by the fact that, in addition to the main diet, the chicks need to be offered additional complementary foods; accordingly, a separate section is required for different foods and additives.

Bunker (automatic)

It is advisable to install such turkey feeders on small farms or where there is a large population of poultry. The design is a large vertical container into which grain or grain mixture is poured. Under the pressure of its own weight, the feed falls into open compartments or cells. In farm supply stores you can find bunker feeders of any size. However, this kind of design, if desired, can be made independently.

Necessary tools for DIY

The set of tools that will be required to make a turkey feeder directly depends on what material will be used in the work. As a rule, the standard list includes:

- hacksaw and (or) knife;

- file for smoothing sharp corners;

- pliers;

- electrical tape or tape;

- fasteners;

- screwdriver or screwdriver.

How to make a turkey feeder with your own hands

You can try to make a device for feeding birds yourself, especially since this does not require any special skills.

From a plastic pipe or bottle

Experienced turkey breeders most often prefer plastic structures for feeding livestock. This is explained by the fact that this material is practical, and everything necessary for making the device yourself can be purchased at any hardware store.

Manufacturing of pipe system

To make your own structure, you will need the following set of tools and parts:

- polypropylene pipes;

- plumbing elbow adapter;

- hacksaw and knife for cutting holes;

- plywood sheet;

- fasteners (screws).

Holes are made in one of the pipes of such a size that a turkey's head can easily fit through it, and then attached to the plywood. Using a plumbing elbow, a second pipe is installed vertically, which serves as a bunker. To prevent the homemade structure from falling apart under the pressure of the bird, the vertically standing pipe must also be secured to the plywood. The feeder is ready.

Making a feeder from a plastic bottle

For self-production you will need the following set of tools and accessories:

- polypropylene pipe ⌀ 20 cm and 35 cm;

- 19-liter water bottle;

- standard set of tools for working with plastic;

- fastener

A larger diameter pipe is attached to the plywood, and then a narrow one is installed in the center. Using a hacksaw, round holes with a diameter of 10 cm are cut out in the plastic. The plastic side in the wide pipe must be preserved. Otherwise, the birds will spread the grain mixture across the floor.The bottom of the water container is cut off, after which the neck is attached to a narrow pipe and secured with tape.

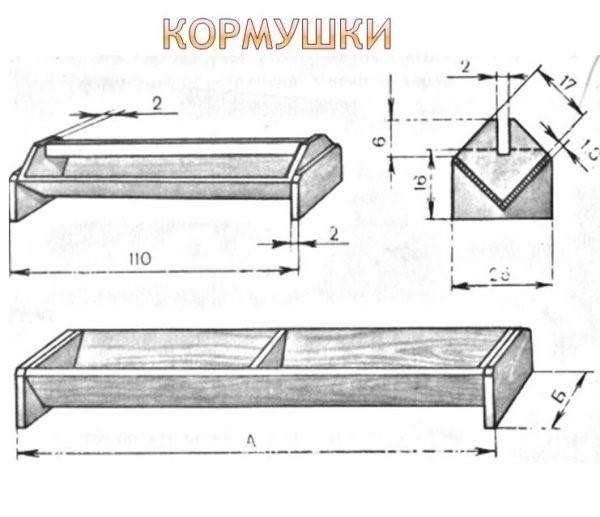

Made of wood

You can make a feeding tray yourself. To do this you will need a wooden beam and sheets of plywood. It is best to have drawings with the dimensions of the product on hand so that you do not have to redo it.

A base frame is made from timber, onto which the plywood sides are attached. To avoid feed spoilage under the influence of precipitation, such trays are installed inside the poultry house or equipped with a special wooden canopy. If you place the tray a short distance from the ground or floor, this will prevent straw, feathers and droppings from mixing with the food.

Hopper feeder

A hopper feeder is most often made from a plastic water bottle. But craftsman farmers make this type of feeder from a wide variety of materials, for example, from a galvanized bucket. To do this, you need to cut a hole in the bottom of the container and insert a pipe into it, through which the grain will be fed into the tray under the pressure of its own weight. The bucket itself is attached to a wooden frame or wall.

To organize feeding of poultry stock, it is necessary to evaluate the conditions of detention, its quantity and age. Based on the situation, you can decide: to make the device yourself or go to a specialized store. Today, feeders of a wide variety of models are available for sale. As they say, for every taste and budget.