Raising rabbits for fur requires knowledge and skills to process the skins after the animals are slaughtered. Available technology allows you to tan rabbit skins at home. This does not require special devices or expensive chemicals. The most important thing is the correct execution of technological operations, observing their sequence and duration.

Skinning Rules

Before cutting the carcass, the rabbit's ears, front paws and tail are removed.The skin is removed immediately after slaughter to make it easier and of better quality. The rabbit is attached to the struts upside down. A circular incision is made on the hock joints and, using a knife, separating the skin from the meat and fat layer, the skin is removed from the thighs to the groin.

In the area of the urethra, sections from the thighs are connected with a transverse incision and then the skin is removed, like a stocking, up to the neck. Then the front paws and head are pulled out. When removing the steamed skin, no effort is made so as not to stretch the dermis.

Required tools and materials

Beginners in rabbit farming need to familiarize themselves with the sequence of work and the requirements for their implementation. At home, the following equipment is used:

- rule;

- scythe/knife;

- acid-resistant container;

- wooden spatula;

- brush.

For processing use:

- salt;

- vinegar;

- formic/sulfuric acid;

- formalin;

- washing powder;

- potassium alum;

- chromium sulfate with basicity 33;

- animal fat.

It is allowed to vary the materials used for processing hides. For example, instead of fat, use machine oil, change the acid.

Stages of tanning skins at home

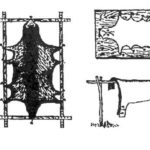

After removing the skin, they do the initial fleshing: they clean off the trimmings of muscles, tendons and fat with a knife. Then the skin is turned inside out and pulled over a rule (a special frame made of metal or wood). The metal rule is made from a rod 4-5 millimeters thick and wrapped with insulating tape, the wooden rule is made from deciduous trees.

Violation of technological requirements will make further processing impossible. After drying, the skins are stacked and stored until dressing, protected from dampness and moths.

Preparatory

Dressing begins with the complete removal of fat and meat residues from the dermis. To do this, it is necessary to perform three technological operations.

Soak

Dry skins must be returned to a paired state. Salt is added to warm water (up to 28 degrees) at the rate of 30 grams per 1 liter, and 1 gram of a bactericidal agent (for example, formalin). There should be enough water so that all skins are covered with a layer of water of at least 1 centimeter.

The soaking procedure lasts depending on the thickness of the flesh and shelf life: 20-48 hours. To ensure uniform impregnation of water, the skins are periodically stirred with a wooden spatula. The end of soaking is determined by the softness of the flesh and the strength of the fur covering. The finished skins are carefully squeezed from the tail to the head.

Flesh

To remove the softened layer from the core, use a knife or a blunt scythe blade fixed at a right angle between two boards. The skins are turned inside out and scraped from the tail to the head and the ridge to the sides. The resulting incisions at the end of the fleshing are sewn up with white threads, with the fur inward, end-to-end.

Degreasing

Cleaned skins are washed in water at a temperature of 20 degrees in washing powder (4 grams per 1 liter). Degreasing is carried out manually or mechanically (in a washing machine) for 30-40 minutes, so as not to damage the fur and flesh. Rinse under running water. They squeeze it out.

Basic

The flesh needs to be protected from temperature changes and getting wet so that the skin does not become deformed or lose its presentation.

Pickling

Acid-salt treatment of flesh.By following the step-by-step instructions, you get a high-quality protective layer, thanks to which the skin does not stretch, dry out, or lose fur. Pickling sequence:

- prepare water at a temperature of 30 degrees;

- add 40-50 grams of salt per 1 liter;

- pour in 70% acetic acid (15-25 grams per 1 liter) or formic acid (10 grams per 1 liter) or sulfuric acid (4-5 grams per 1 liter);

- place the skins in the solution for 16-24 hours (until drying appears);

- stack in a container to keep for 12-24 hours in a warm place.

“Drying” is a mark on the flesh, by which it is determined that pickling is completed. To do this, bend the skin in the groin area and run it along the flesh with a fingernail. A white line should be imprinted on it, which disappears after a few seconds.

Pickling

A process equivalent to pickling for its intended purpose. The difference lies in the materials used, the duration of the technological operation and some difference in the final result. For fermentation, sour milk or sourdough is used. It is rarely used at home, as it requires long washing to clean the fur in the future.

To remove the skins, prepare a starter from rye, oatmeal, wheat flour and yeast, or use sour milk. The inside of the skins is smeared with a thick layer of leaven. Stack them and cover them with polyethylene. A day later the procedure is repeated. Ripening time is 2-3 days. The temperature in the stack is no more than 35 degrees. Readiness is checked by drying. The strength and elasticity of “fermented” skins is 2 times higher than with acid-salt pickling.

Tanning

The subsequent operation is designed to create a protective film over the softened collagen layer.For tanning, chromium sulfate with a basicity of at least 33, or potassium alum, or a mixture thereof is used. Aluminum-potassium alum produces white, soft flesh, but when exposed to moisture, it is washed out, which leads to a roughening of the skin.

In home dressing, chrome tanning or chrome-alumina-potassium tanning is more often used.

Tanning agent content in 1 liter of water at a temperature of 25-28 degrees:

- chrome – from 4 to 7 grams;

- potassium aluminum – 10-20 grams;

- mixtures - 4 grams of each.

The step-by-step tanning procedure consists of 4 parts. First, the skins are placed in a ready-made tanning agent for 6-7 hours. Then, every hour, add a deoxidizing agent (neutralizer) from baking soda and water (330 milliliters each at the rate of 3 grams per 1 liter).

Fatliquoring or fattening

To protect the tanning agent from washing out the skin, it is necessary to treat it with a fatty emulsion. It consists of pork fat (200 grams), boiling water (500 milliliters), 25 milliliters of machine oil, 40 milliliters of glycerin, 200 grams of egg yolks.

The tanned skins are pulled over the rules, coated with a brush and hung to dry.

Finishing

The preparation of rabbit skins with your own hands ends with a simple operation: the dried skins are removed from the rules, gently kneaded and stretched, achieving softness and elasticity. The fur is combed, the inside is rubbed with chalk, and sanded with sandpaper. The hair is wiped with gasoline/technical alcohol and combed.

Alternative finishing options

Tanning at home is possible without chemicals. The raw materials for tanning are the bark of trees or grass: willow, spruce, oak, horse sorrel. A simple way to prepare tanning agent is a decoction. For example, a 50-liter metal container is filled to the top with grass, filled with water, brought to a boil and left for 30 minutes.Cool to 30 degrees, add salt, filter. The skins are placed in a decoction for several days. The end of tanning is checked by cutting the flesh: it must be the same color throughout its entire depth.

Classification of rabbit skins

For dressing, the gender and age of the rabbits matter. The thickest flesh is in males over a year old, the thinnest is in 5-6 month old rabbits. At the same time, the composition of chemicals, temperature and duration of operations are adjusted.

According to Gosstandart, when accepting skins for fur production, varietal differences relate to the size of the skins, the quality of the hair and flesh, the presence and types of defects.

Skins are classified according to the method of drying after slaughter for long-term storage:

- fresh-dry;

- salty-dry;

- frozen.

In the first and second methods, the skins are dried on the rules with the fur facing out. The flesh is/is not sprinkled with salt before stretching. Unprocessed skins are used as raw material for further dressing or obtaining fluff for felt products. When freezing, paired skins are folded individually, fur side out, into plastic bags and placed in the freezer. Freezing temperature – 18-32 degrees. Skins are a semi-finished product for producing fur products after dressing.