For a successful farmer, a separator is one of the main devices. The simple unit instantly separates the milk into nourishing cream and empty skim milk. Using separation, sour cream, butter, cheese and other dairy products are made. The principle of operation of a milk separator has not changed for more than a hundred years, but once upon a time the process of separating cream took a lot of time and was not so effective.

What is a milk separator?

For several centuries, people obtained cream by simply settling milk.The process was long, and the result had to wait a whole day. Until 1878, gravity was the only way to separate cream from milk.

In the second half of the 19th century, the Swedish engineer Gustav de Laval introduced the world to a miracle - a device called a “separator”. Using centrifugal force, the device separated milk into fatty fractions and skim milk.

Modern separators differ little from their predecessors - their operating principle has not changed. The device is necessary to obtain any dairy product. Using a separator, the farmer makes butter, sour cream, cream, and cheese. The separator not only separates milk into different fractions, but also cleans the product from accidental contaminants.

Operating principle and device

The principle of operation of the device can be considered using the example of a household separator.

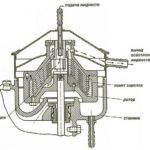

- Milk is poured into the drum of the device. The whole product rotates in the drum at a speed of 10,000 rpm.

- As a result of centrifugal force, heavy, fatty fractions (cream) are pressed against the walls of the device (thin layer).

- The skim part of the milk is concentrated in the center of rotation (thick layer).

- After the drum stops, the cream and the skim part are drained from the separator through separate channels.

The breakdown of milk into individual components is possible due to the special structure of the substance. The product consists of microscopic particles floating in a liquid medium. The density of fat and skim particles is very different. Fatty particles separate from milk more easily and, if the product is left for several hours, the cream will appear at the top of the vessel with the drink.The separator allows you to significantly speed up the process of splitting the product.

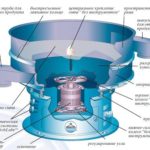

There is a drum at the top of the unit. The container is driven by a gearbox. The drum consists of perforated cones – plates – stacked on top of each other. The elements are equipped with small spikes. They prevent the plates from sticking together. A space is created between the spiked plates in which the milk is split.

A set of plates is placed on a glass installed in the base. The upper distribution cone is equipped with special outlets for draining the skim milk and the fatty part of the milk. The outlets are connected to outlet horns. Through them, the finished fractions fall into the placed dishes. A fat content regulator is also installed there.

In addition, the upper part of the drum is equipped with a cavity for the accumulation of foreign impurities.

The unit is closed with a lid, the upper part of which is equipped with a float chamber. The device is designed for precise dosing of milk when feeding the product into the drum. A milk bowl is installed on the top of the separator. Through a special hole, the product enters the float chamber, and then into the drum container. The lower part of the unit consists of an electric motor or a manual drive. Most often, the device runs on electricity.

Types of separators

Modern units are divided into several types. Each of them performs a specific function and differs from other devices in its design features and characteristics.

Devices are divided into 2 types:

- Powerful industrial machines designed for processing large quantities of milk. Complex installations are used in food industry enterprises.

- Separators intended for domestic needs. The unit is widely used in small farms.

Depending on their purpose, separators are divided into different types:

- Normalizing devices. They are used to prepare milk of a certain fat content.

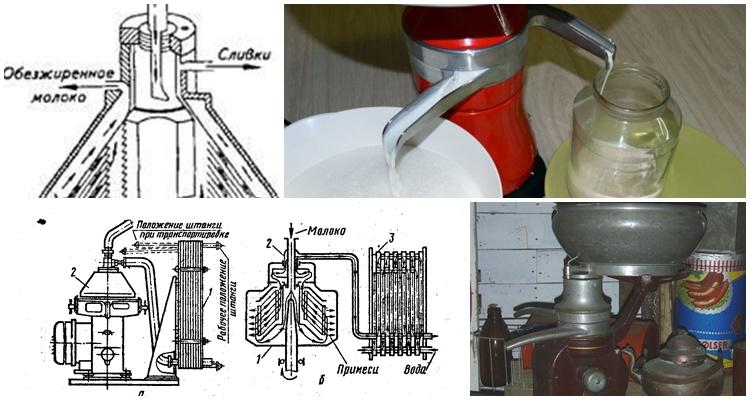

- Cream separators. They are used to split milk into heavy cream and skimmed milk.

- Cleaning units. The devices clean the product from impurities and contaminants. The operation is performed without separating the milk into separate fractions.

- Universal separators. At the same time, the cream is separated and the milk is cleaned of impurities.

- Apparatus for separating curd mass (curd) into whey and curd.

- Devices for clarification of separated whey.

- Clarifier installations. Used for the homogenization and clarification of milk.

- Devices for additional degreasing of separated whey.

Most of the listed devices are used in food factories. For a small farm, it is enough to purchase the simplest, most universal unit.

Based on their design features, devices are divided into 3 types:

- Household open type separators. In this case, the product comes into contact with air masses, both at the inlet and outlet. It should be noted that due to exposure to air, milk produces strong foam. This has a bad effect on the quality of operation of the unit.

- Semi-closed devices. Here the milk comes into contact with air masses only when fed into the drum. But the final products enter the containers through closed outlet paths.

- Closed installations. Complex devices ensure that milk is processed without access to air. Unfortunately, such devices are only a component of industrial equipment.

Household devices are divided into units with manual or electric drive.

Selection rules

When purchasing a separator, you need to decide on the scope of future work.A household home unit can easily cope with processing a small amount of milk. To do this, it is enough to purchase a device with a capacity of 50 l/h. Recommended capacity of the receiving bowl is 5-10 liters. To process farm products, you will need a powerful separator - 500 l/h.

The expected frequency of use of the device is of great importance. For heavy loads, it is recommended to purchase equipment with metal components.

In other cases, you can opt for a plastic separator. Devices with mechanical or electrical control are available for sale.

Electrical units are more convenient and much more powerful than mechanical devices, but if there is no power supply, the equipment will be useless. Experienced farmers recommend purchasing both types of separators.

How to assemble a milk separator?

Work begins with drum assembly. The prepared container is installed on a special spindle. Then containers are installed to receive heavy cream and skimmed milk. The drum is closed with a lid, and a bowl for milk is placed on top. Raw materials are poured into the prepared bowl and the device is turned on. Using the fat content regulator, the operation of the separator is adjusted. If the procedure goes well, the device operates quietly, without vibration or knocking.

Instructions for use

Using a household separator is not difficult, but for successful operation you must follow some rules:

- For the separation procedure, milk must be prepared. The raw materials are heated to a temperature of 38-40 degrees. The thin film formed on the surface of the milk is removed.

- The device is turned on and allowed to run in idle mode for 3 minutes.Then 1 liter of water is poured into the drum and driven through the separator. After preparation, the unit can be used to process milk.

- Prepared milk is poured into the receiver bowl. During operation of the device, you need to monitor the flow of separated fractions. The heavy cream will appear first, and then the skim milk will come.

- To obtain cream with the highest degree of fat content, it is necessary to adjust the drum. To do this, tighten the adjusting screw to the end, and then turn it in the opposite direction by 1.5 turns. If it is necessary to obtain medium-fat cream, the screw is again tightened to the end, and then turned in the opposite direction by 3.5 turns.

- Before starting and finishing the procedure, the separator is thoroughly washed with hot water. Baking soda is used as a cleanser. The unit is washed with a soft sponge or cloth. Do not use steel wool or aggressive cleaning powders.

Possible faults

The use of milk with a high level of acidity leads to problems in the operation of the separator. In this case, fat particles end up in skim milk. As a result, protein fragments overflow the dirt collection container. The device has to be stopped frequently to clean the plates.

The efficiency of the separation procedure is reduced if the drum is installed incorrectly. If the container sits too low on the spindle, most of the cream ends up in the return.