A modern feed dispenser for a cattle farm is a functional technique that reduces labor costs and saves feed for livestock. The equipment is aimed at the correct and uniform distribution of mixtures in accordance with zootechnical standards and requirements. The unit crushes and mixes feed. There are stationary and mobile equipment.

Purpose and principle of operation of the mechanism

The dispenser is designed not only for distributing food for the livestock, but also for receiving, delivering, and mixing ingredients in a given ratio. They are effective for dry, succulent and liquid feed.

The technical device distributes the feed mixture into the feeders in doses, moving along the rows and unloading on both sides. There are a number of requirements for automated feed dispensers:

- preservation of feed in its pure form;

- strict dose monitoring;

- supply of feed at a certain time;

- precise proportions and uniformity after mixing;

- safety for livestock and employees.

Feed is loaded in bales into the hopper of a mobile dispenser, where the grinding and mixing process takes place A similar mechanism is necessary for a large farm. For small farms they use stationary devices, for larger ones - mobile ones.

The operating principle and maintenance of the equipment do not cause any difficulties. Feed is loaded into a special container in strict accordance with the norm. This is possible with the help of dispensers. Next, the resulting mixture enters the conveyor or directly into the feeders. The conveyor is looped, so the distribution is completed as soon as the first scraper, having captured the mixture, rotates in a circle. The drive then switches off automatically.

Advantages and disadvantages of application

The main advantages of mechanical distributors are that with their help the farmer controls feed consumption. Such a mechanism allows you to increase the income of the enterprise, reducing maintenance costs. Other advantages of the mechanism are as follows:

- temperature control of supplied feed and mixtures;

- transportation of feed mixtures and loading into feeders;

- grinding, homogeneous mixing and other types of feed preparation before serving;

- self-loading using a mobile bucket;

- electronic weighing, precise dosing of food served.

Thus, automatic feed dispensers significantly reduce the cost of production and facilitate working conditions.

The units have no disadvantages, however, individual models may not meet the farmer’s expectations, since each has different technical characteristics and capabilities. Before choosing a mechanism, you should familiarize yourself with the types and classification of equipment.

Classification of feed dispensers

Mobile dispenser at work

Today, manufacturers of agricultural machinery are ready to offer a wide selection of various units. They differ in carrying capacity, methods of movement and distribution.

By way of movement

Feed dispensers are divided into two groups: mobile and stationary. The mobile unit is a self-propelled machine with an electric drive. She independently moves around the farm and delivers food to each feeder.

Stationary types of feed dispensers are installed in the room where animals are kept. They are arranged in the form of feeders with a conveyor. The automatic line mixes, grinds the feed, and then distributes it in doses from the hopper.

Stationary devices are divided into the following types:

- scraper – equipped with a chain-scraper mechanism;

- belt - move using a roller belt;

- platform – feed is supplied by a conveyor;

- cable-washer – feed mixtures are delivered to the feeders by a cable with washers attached to it.

Stationary mechanisms are used in any type of premises where it is difficult to use other equipment due to narrow passages.

By distribution type

Equipment is distinguished by the type of mixture supply. Some models dispense feed from one side of the stalls; a number of mechanisms can dispense food from both sides of the feeders (single- or double-sided dispenser).

By load capacity

Load capacity determines how much weight the dispenser can lift and deliver. This classification is especially indicative of mobile mechanisms. It depends on the axles of the tractor, as well as on the carrying capacity of the chassis of the vehicles where the feed dispenser is located.

Average load capacity: from 1.1 to 3 tons for single-axle mechanisms, from 3.5 to 4 tons for equipment with a pair of axles. You need to choose a device based on the needs of the livestock complex.

The best feed dispensers for cattle farms

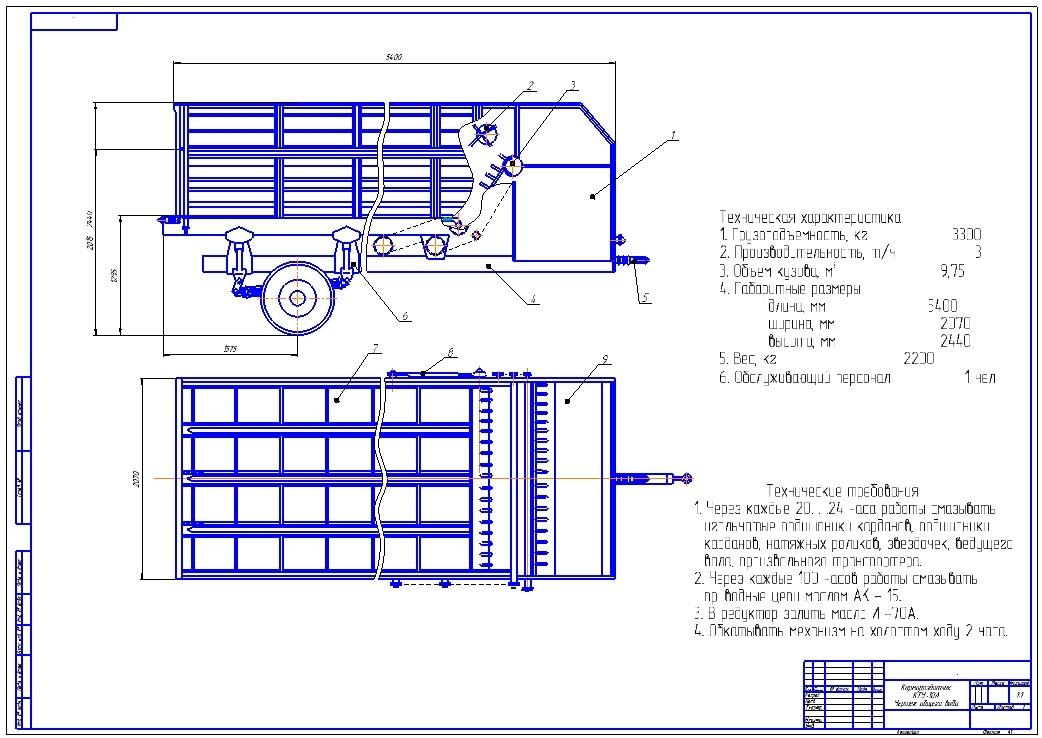

Drawing of mobile equipment KTU-10

When choosing, it is recommended to pay attention to the following technical characteristics and parameters of the mechanisms:

- bunker capacity - it will show how much feed the dispenser is capable of distributing in one loading;

- the most important characteristic is the dimensions; if this is not taken into account, it will be difficult for mobile devices to enter some rooms;

- magnetic catcher to prevent metal parts from getting into food;

- self-loading and electronic weighing system;

- screws that affect performance during mixing, grinding and feeding.

Before purchasing, you should carefully check the technical condition of the unit.

Stationary

Stationary model

The most popular models include:

- KRS-15. This model is a conveyor dispenser with a horizontal open position. Belongs to the scraper type. The conveyor is equipped with two distribution channels and runs along the bottom of the feeders. Starting the device begins with the operation of the electric motor. First, the feed is fed over the fence, then distributed by scrapers. The drive switches off spontaneously when the scraper goes through a full revolution.

- TVK-80B. The technique is ideal for dry and solid food. It is based on a belt mechanism that resembles a closed ring. It is driven by a motor. From the bunker, the feed mixture is supplied in equal parts to the feeders, then the mechanism is turned off.

- RK-50. The mechanism is equipped with a conveyor belt, which is located above the feeder. The model has two options - for a livestock complex for 100 and 200 animals. The basis of the feed dispenser is a control unit, an inclined and transverse conveyor, as well as a pair of dispensers. The length of the feeding object is about 75 m, with a productivity of 3-30 tons per hour.

Comparison table of stationary models

When choosing a stationary model, it is important to take into account productivity, number of heads, and length of the feeding area.

|

Model |

Number of goals |

Feeding area length |

Performance |

Engine power |

Weight |

|

KRS-15 |

180 |

40 m |

15 t/h |

5.5 kW |

1540 kg |

|

TVK-80B |

65 |

74 m |

38 t/h |

5.5 kW |

3300 kg |

|

RK-50 |

up to 200 |

75 m |

3-30 |

9.7 kW |

5400 kg |

Mobile

Supply of mixtures by a mobile unit

Among the mobile units, the most interesting and functional are the following:

- KTU-10. The feed dispenser model deserves attention, but it is worth noting right away that it cannot work in narrow spaces due to the small turning area of the equipment. The unit can be driven on a tractor trailer.It is equipped with several beaters, an unloading and a transverse conveyor. The speed at which food is supplied to the feeders directly depends on the speed of the machine.

- ISRK-12. The feed dispenser is designed for large farms and has wide functionality. Loading can be done in rolls without sorting out the feed in advance. Special additives are poured into a separate window. While the machine is operating, feed is crushed and thoroughly mixed. The model is equipped with a two-stage gearbox with 4 auger rotation speeds and a remote control panel from the machine cabin. An additional function is an electronic system for weighing ingredients and memory for dozens of recipes from different components.

- RMM-5.0. This model is considered small-sized because it is convenient to use in narrow spaces. The feed dispenser is adapted to work with various modifications of the Belarus tractor and other equipment. Refers to multifunctional single-axis models.

The units can be used even more efficiently, since manufacturers meet customers halfway and can adjust the models to specific conditions on the farm.

|

Model |

Hopper volume |

Feed rate |

Performance |

Power engine |

Weight |

|

KTU-10

|

10 m3 |

3-25 kg/m |

50 t/h |

7,5 |

2200 kg |

|

ISRK-12 |

12 m3 |

15-150 kg/m |

7.8 t/h |

5,3 |

4500 kg |

|

RMM-5.0 |

5 m3 |

1-16 kg/m |

3-38 t/h |

6 |

1370 kg |

Comparison table of mobile feed dispensers

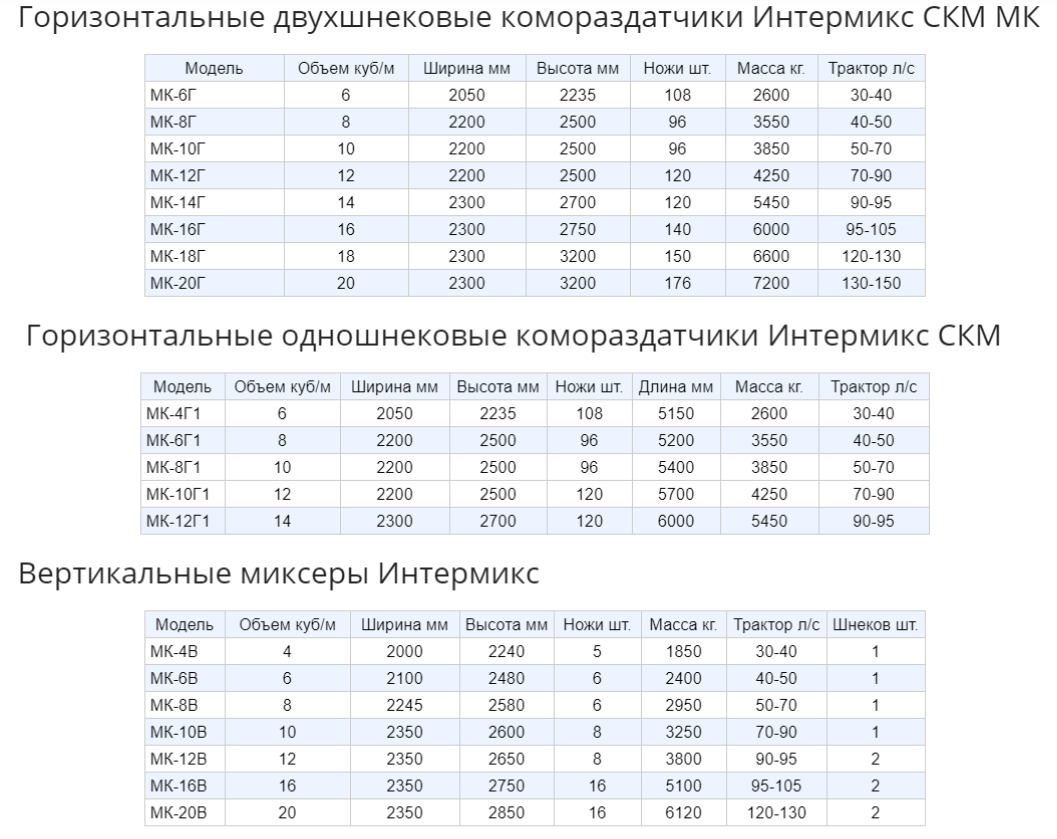

Automatic feed dispensers with mixers are very popular among farmers, which quickly deliver feed mixtures to animal feeders, having previously prepared them. Feed mixers, which are offered to farmers by the Intermix company, are well suited for these purposes. The equipment is capable of working with all types of feed for cows - grass and silage, grain crops, root crops and granulated feed of different fractions.

The models are varied, have different modifications, and, accordingly, characteristics:

Terms of use

Before starting work, the equipment must be checked for malfunctions and breakdowns; you should also make sure that the grounding and protective fences are reliable.

Before loading feed, it is necessary to check the unit at idle speed.

Further maintenance should consist of periodic lubrication and checking the condition of mechanisms and components. Regardless of the feeder model, it is important for cattle farms to regularly clean out feed residues and dirt.