Beekeeping isn't just about bees and hives. To produce by-products, additional tools must be used. For example, to produce wax you will need a wax melter, which you can make yourself. The mechanism has some peculiarities, but it is not difficult to make. It is necessary to study the recommendations of beekeepers, types and methods of production.

- What is a wax grinder and its principle of operation

- Advantages and disadvantages

- Types and designs

- The simplest

- Framework

- Electric

- Solar

- Centrifugal

- Drawings and dimensions

- How to make a wax grinder with your own hands

- From the refrigerator

- From a pressure cooker

- From the frying pan

- From the washing machine

- From a 200 liter barrel

- Is it possible to do without a wax grinder?

What is a wax grinder and its principle of operation

The purpose of the equipment is easy to see from the name - this is the mechanism with which the beekeeper obtains wax by melting it out of frames and honeycombs. The material is exposed to high temperature until it softens. After preparation, the wax is poured into a separate container, then packaged in a pre-prepared container.

The processing process consists of several stages:

- honeycombs and frames must be soaked (time depends on the amount of material);

- move the prepared elements to the unit;

- Heat the wax melter to the required temperature so that the wax begins to melt.

The principle of operation is simple, so beekeepers often do not buy ready-made equipment, but make it themselves. Read more about the principle of operation in the video.

Attention! Once melted, the wax takes time to dry. The time required depends on the type of honey produced by the insects. The average is two to three weeks. Manufacturers indicate the time - from 3 to 6 hours. But to speed up the process, some unscrupulous manufacturers use chemical thickeners.

Advantages and disadvantages

The devices operate on a simple principle, there are positive and negative sides. Advantages of a do-it-yourself wax grinder:

- a significant percentage of the material obtained;

- a small amount of water in the finished product;

- the size of the product allows it to be moved without difficulty;

- you can quickly clean the internal elements from melting products (garbage, impurities, residues).

There are few disadvantages - electrical devices consume a large amount of energy. Purchased or homemade options often lack a thermostat, which leads to a deterioration in the quality of the wax.

Types and designs

There are several types of devices, each of which has certain advantages and disadvantages. Often the simplest designs are used in apiaries, including frame, electric, solar and centrifugal. How to make it yourself is shown in the video.

https://www.youtube.com/watch?v=Jc8arREvW5k

The simplest

This option is easy to make yourself. Principles of operation and assembly of the simplest type of wax refiner:

- a steel cylinder is used as the main element (for example, empty from liquefied gas or from a metal barrel);

- the base is installed above the fire source (this could be a stove, gas burner, or another option);

- pour water inside and install a grate.

A grid with crushed honeycomb is placed in the upper part of the structure, and a bowl is placed on the grid. This creates a mechanism that runs on steam. You can install a lid on top to speed up the process.

Framework

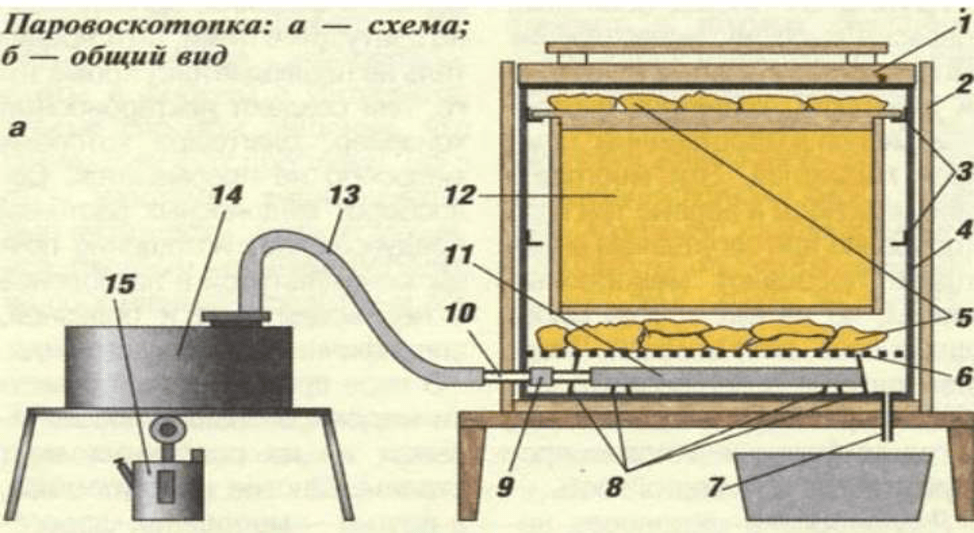

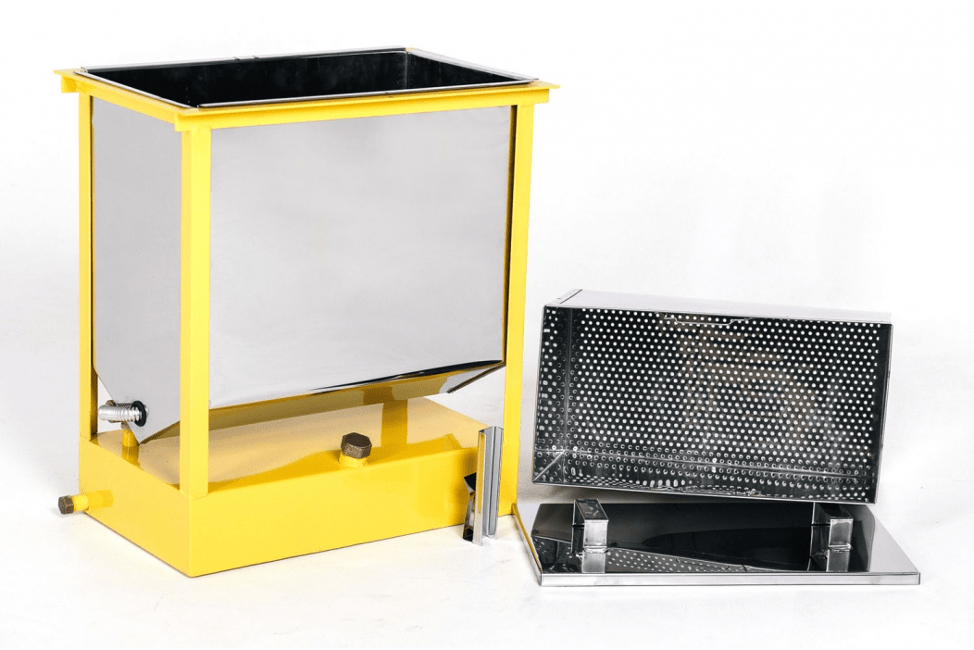

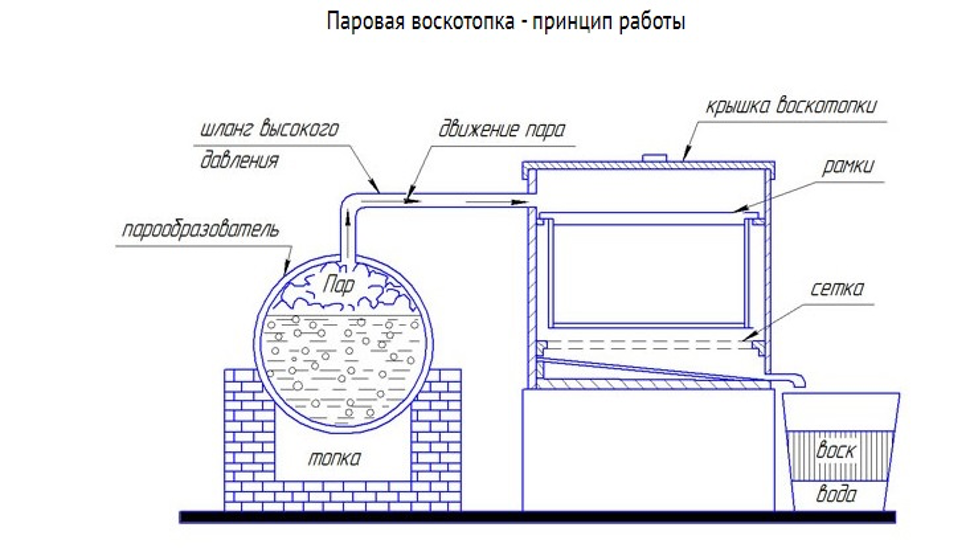

This option usually consists of a rectangular tank. The material of manufacture is alloy steel; a steam generator is used as a working element. At the top there are frames through which melted wax flows. In industrial devices, filters and separate receiving containers are additionally installed.

Electric

According to the principle of operation, this type of wax refiner is similar to solar. The difference - as the name suggests - is that the structure includes an electric steam generator or heating device. In addition, sensors and temperature controllers are installed. Usually these are flat infrared elements, small in size.

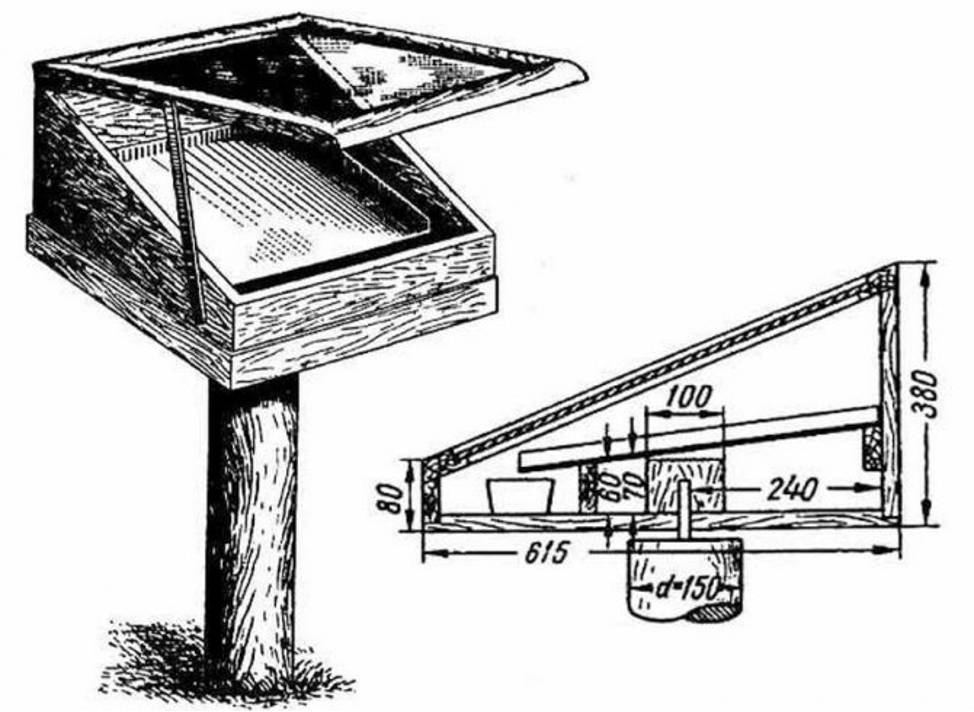

Solar

This type of design runs on solar energy and has the advantage of saving electricity. Great for southern regions where the weather is sunny most of the time. An additional positive side of using this type of mechanism is the brightening of the finished product. Features of the structure:

- glass box with lid (also made of glass);

- a canvas with holes is installed inside, where wax material is placed (honeycombs and frames, sufficiently crushed);

- During the heating process, the box heats up to 120 degrees.

Clear weather is important for heating. Some beekeepers, to heat up the glass box faster, paint the walls of the device black.

Attention! A solar wax melter is considered the best option for obtaining wax. The output is a product of fairly high quality, without watery impurities (which are inevitable in steam-type devices).

Centrifugal

This type is difficult to make at home. The main elements are a centrifuge and steam generators. In this case, honeycombs and frames are wrapped in plastic film and then distributed along the inner walls of the device. Then they are started manually or using an electric drive. After kindling, the finished liquid product enters the receiving container through a separate tube.

Drawings and dimensions

To make a high-temperature wax melter with your own hands, use ready-made drawings or diagrams prepared independently.

The main advantage of any of the presented types of devices is that you do not need to follow strict parameters; it is important to follow the principle of operation of the steam generator and the removal of the finished product.

How to make a wax grinder with your own hands

A device for burning wax can be made from available materials.Various materials and even broken electrical appliances are used.

From the refrigerator

This version of a homemade wax melter is suitable for owners of large apiaries. An old, used refrigerator is suitable for assembling a suitable device. Distinctive features:

- Up to 30 frames can be loaded inside at the same time - along with honeycombs (the number depends on the size and parameters of the resulting steam);

- before assembly, you need to check the material from which the refrigerator is made - only aluminum or iron is allowed (so that steam does not damage the surface and metal particles do not get into the finished product);

- you need to prepare tools and suitable materials - an empty frame, a wire mesh, hoses, containers through which hot air will be supplied, a suitable drawing or diagram.

The elements are assembled according to the general principle, according to the chosen scheme. It is important to check that there are no unnecessary holes left.

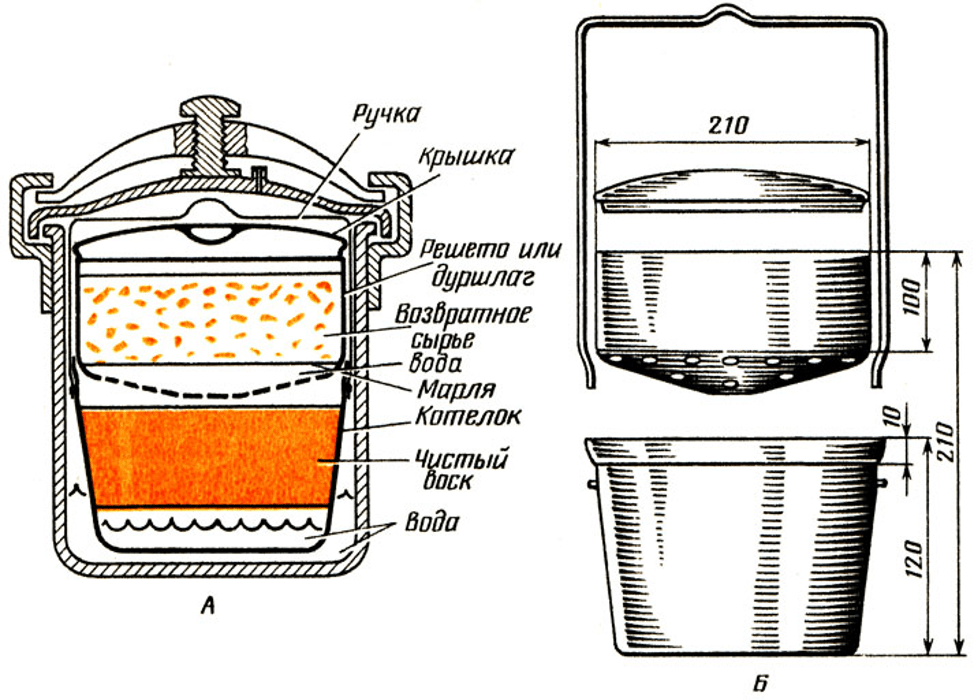

From a pressure cooker

To convert old kitchen equipment into a working wax furnace, you need to prepare additional materials - an aluminum sieve with a diameter of 18 cm, a camping pot (or something similar). Work process:

- soak the elements, boil a little and cool;

- pour a glass of water into the pot;

- Place a piece of gauze on the sieve (secure with twine);

- Place a sieve inside the pressure cooker, place the soaked honeycombs, and close the lid.

The assembled structure is installed over an open fire. The maximum temperature that can be achieved inside such a device is 120° C.

From the frying pan

If you find an old, unusable frying pan on your property or dacha, you can make a wax melter. Processing method for honeycombs and frames:

- Pour 1.5-2 cm of water inside the frying pan and place on open fire;

- Place the crushed honeycombs in a glass container;

- Place the jar in a frying pan with water.

The heated liquid will begin to melt the wax. Periodically, the material needs to be kneaded with a fork and mixed. The melted elements will need to be filtered through several layers of gauze.

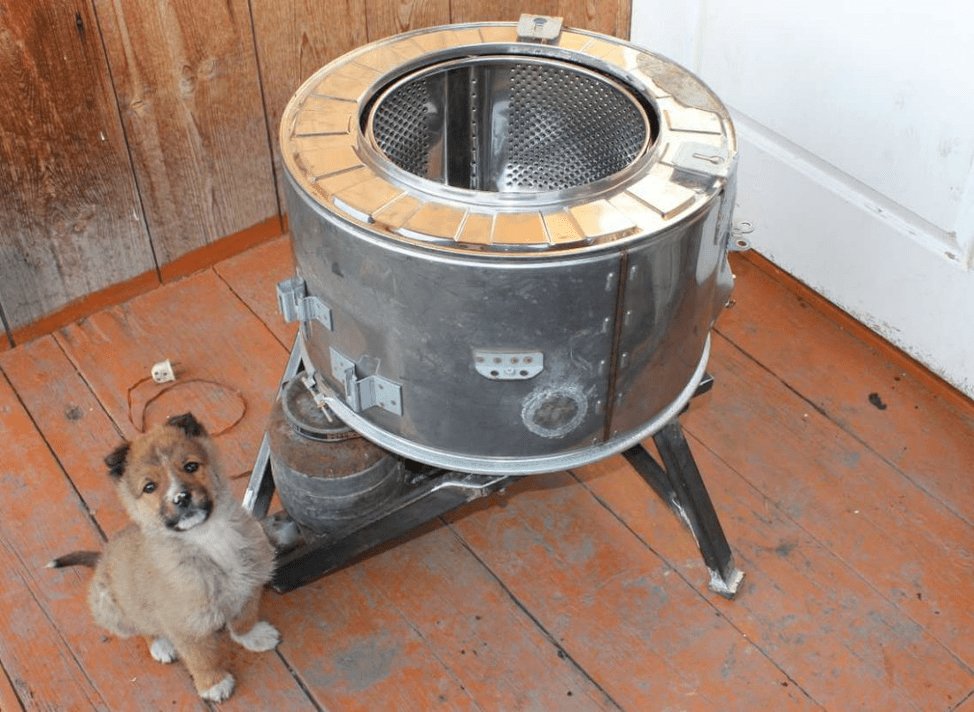

From the washing machine

The principle of assembly of the work is similar to other designs. An internal tank is used - only stainless steel, carbon steel is not used. The bottom is cut off, the resulting hole is covered with a grate (the edges are welded). Use a saucepan (about 20 liters) as a container with water. At the same time, you can melt wax removed from approximately 22-25 frames.

From a 200 liter barrel

The manufacturing principle is identical to the previous paragraphs. The bottom of the barrel must be cut off and replaced with a mesh grate. The honeycombs are crushed and placed in a container with heated water. It is important to stir the softened honeycombs in a timely manner so that lumps do not form.

Is it possible to do without a wax grinder?

To melt wax without additional equipment, you must follow these steps:

- prepare a container (deep, made of stainless steel or aluminum, it is unacceptable to use iron, brass, copper);

- collect raw materials (old honeycombs, foundation, bedding are suitable), transfer to a glass container, leave for several days;

- change the liquid to clean, transfer to a bowl, then to the fire;

- bring to a boil, reduce heat.

Attention! The heat treatment time of the collected material depends on the condition of the raw material. For example, if mold was found on the honeycombs or frame, then the reheating time cannot be less than two hours.

Reheating honeycombs, bars and frames is one of the stages of beekeeping.Wax is used for candles and the manufacture of decorative products, as well as in the production of other elements. You can use a purchased device, make the mechanism yourself, or do without it - the choice is up to the beekeeper.