Beeswax is a valuable substance produced by the wax glands of insects for the construction of honeycombs. The composition is a multicomponent mass, which can have a white or yellow-brown tint and a characteristic honey aroma. Under the influence of sunlight, the substance becomes lighter. The melting point of wax is important to consider when making various cosmetics and other products.

Melting temperature

At a temperature of +35 degrees, beeswax is in a solid state. When the product is heated above this value, it acquires a plastic consistency.The average melting point of this mass is +69-72 degrees. This range is associated with the presence of impurities in the composition and the method of obtaining raw materials:

- The melting point of the plates, which are made directly by bees, is +72 degrees.

- If the wax is obtained by melting and pressing, it changes consistency at a temperature of +62-65 degrees.

- The wax obtained by extraction is heated at +69-71 degrees.

When the wax is heated to +95-100 degrees, foam appears on its surface. This is due to the presence of water in the composition. At +100 degrees it begins to boil, which leads to the formation of foam. As the temperature of the mass increases, it is important to carefully monitor the process. If the wax contains a lot of moisture, it may boil away.

After the water in the wax has completely evaporated, the foaming process stops. If the raw material does not contain soap, alkali or other impurities, it does not contain emulated water. As a result, there will be no foam formation.

If the temperature exceeds +120 degrees, decomposition and evaporation of some components in the raw material are observed. When the readings reach +250-300 degrees, complete decomposition of the wax occurs. At this stage, the mass begins to burn. It is important to note that wax vapors are considered highly flammable. This creates a fire hazard.

What does wax dissolve in?

There are quite a lot of liquids in which beekeeping products can be dissolved. When using them, it is important to take into account a number of features and nuances.

Alcohol

First, the alcohol and the wax mass need to be heated, and this must be done separately. It is important to note that it is prohibited to bring substances to a boil. Then it is recommended to combine the slightly heated products, mix well and put on low heat. The wax melts within a few minutes. The result is a liquid mass that has a uniform consistency.

Turpentine

This substance is also an excellent solvent. In this case, the mass must be heated in a container that is not afraid of the influence of aggressive substances. An enamel container is quite suitable for this purpose. In order not to spoil the wax mass, it is recommended to add turpentine little by little. The finished product must be kept in the refrigerator.

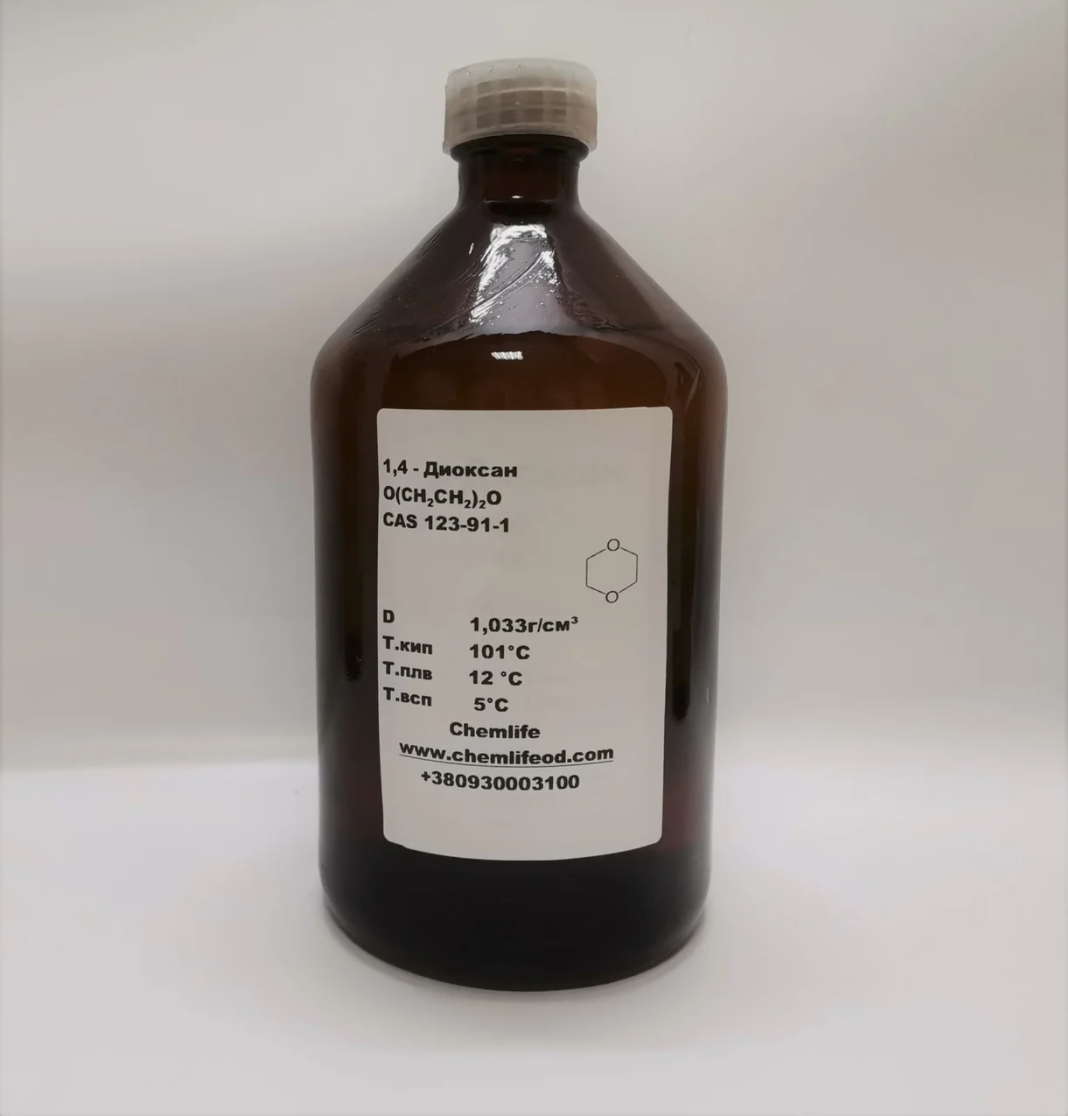

Dioxane

It is quite possible to dissolve wax in dioxane. This substance is a clear, colorless liquid that has a slight ethereal odor. The mass is highly flammable and easily mixes with water.

When using dioxane, ensure good ventilation in the room. The use of personal protective equipment is of no small importance. When working with chemicals, you should use safety glasses, special overalls, gloves, and a respirator.

Chloroform

To make a paste for coating wood, you can dissolve the wax in chloroform. However, this method is considered longer. In this case, chloroform does not need to be heated. All you have to do is take the foundation and pour the chemical into it. Then you just need to wait for the mass to melt. This procedure takes from several hours to a day.

To quickly bring paraffin to a liquid state at home, chloroform can first be heated in a water bath. After that, the resulting mass must be poured with beeswax.To enhance the effect, experts advise adding formic acid to the composition. Acetone can also be used for this purpose.

Petrol

Natural wax can be easily dissolved in gasoline. Moreover, this can be done in different ways. In the first case, it is recommended to take gasoline and wax in a ratio of 1:3. To achieve the required results, you should do the following:

- Clean solid raw materials from visible contaminants and grind them.

- Place the prepared product in a suitable container. It is best to use enamel or porcelain dishes.

- Fill the contents of the container with gasoline. It is important that it completely covers the foundation.

- Place the container in a dark place. It is recommended to ensure that the sun's rays do not fall there.

After complete dissolution of the beekeeping product in gasoline, you will be able to obtain a thick mass. At the same time, it should have a uniform consistency.

In the second case, the paraffin also needs to be cleaned and crushed. After which it needs to be placed in a container and heated using a water bath. This must be done at a temperature of +60-70 degrees. When the mass acquires a soft consistency, gasoline should be added to the composition. It is recommended to do this in small portions.

Then the substance must be thoroughly mixed and poured into a glass container. It should have a tight-fitting lid. The disadvantage of this method is that the resulting composition cannot be stored for a long time. It must be used immediately. It is important to take into account that wax compositions made using chemical components can only be used externally.

Beeswax is a very valuable beekeeping product. Moreover, it is characterized by a certain melting point.This must be taken into account when producing various wax-based products. Various compounds can be used as solvents for this substance - alcohol, dioxane, chloroform, gasoline.