Foam that forms on wine must during fermentation is normal. But this only applies to foam of a certain intensity. If the wine foams more than usual, this indicates that there are irregularities in the process. The reason should be found out. Let's look at why wine foams a lot during fermentation and how to solve this problem when making wine at home.

Danger of increased foaming

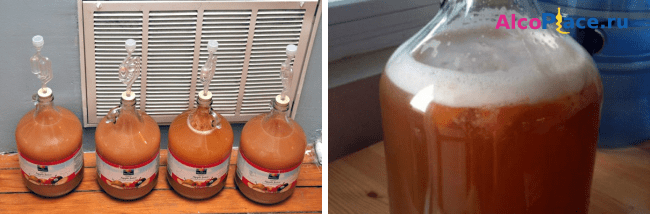

The presence of foam indicates the yeast is working. If everything goes well, the normal height of the foam layer during fermentation is 3-15 cm.If the foam has risen too high or occupies all the free space of the bottle, or even comes out through the water seal tube, this means that the correct fermentation conditions have not been met.

The active fermentation stage begins 6-18 hours after adding yeast. It lasts 7-12 days. During active fermentation, a lot of carbon dioxide is released, which is why foam is formed. It is during the active fermentation stage that the problem of increased foaming may arise. The yeast then moves from the top layer of the wort downwards and there is less foam.

Foam trapped in the tube can clog it, the gas will not be able to escape and will accumulate in the container. The pressure in it will increase, in some cases it can knock out the water seal or even rupture the container. If this does not happen, the products that should have been removed will remain above the wort and spoil its taste and smell. Fermentation may stop.

Why does wine foam?

If the wine foams a lot when poured, this may be normal. You need to wait 2-3 hours, if the layer does not rise, then everything is fine. Foaming depends on several factors:

- Raw materials. Juice from plums, pears and cherries produces a lot of foam. Grape and apple juice - less. The color of the foam also depends on the type of fruit and berries.

- Type of yeast. Special wine yeast promotes less foaming than wild yeast, which is found on the surface of fruit.

- Temperatures.If the temperature in the room where the bottle with wort is located is higher than necessary, then the process accelerates and thick foam appears.

To control the situation, you need to follow these criteria.

Ways to solve the problem

There are several ways to stop foaming and reduce the already formed layer. Each of them is applicable in a specific situation.

Do not stir the wort, after which it will foam even more actively. The correct conditions for wine fermentation: constant room temperature, without sudden changes that change the activity of the yeast. There should be no drafts; the container should be in a dimly lit or darkened place. Under the influence of ultraviolet light, part of the alcohol turns into acetic acid, which reduces the degree and makes the wine more sour.

Split the wort

This method works when a container was initially used, in which there was little free space left after pouring in the liquid.

If there is less than a third of free space, you need to pour some of the juice into another container. Install a water seal on each.

Remove foam

According to this method, you just need to remove some of the foam from above. The method has a drawback - the yeast is removed along with the top foamy layer. Therefore, you need to remove it carefully so as not to stop the fermentation.

Reduce temperature

The normal temperature that must be maintained for proper fermentation is 18-24 °C. It is in this range that the winemaking process occurs correctly. But if the temperature reaches 30 °C and above, the yeast multiplies too actively and releases a lot of carbon dioxide, alcohol formation occurs faster. At 16 °C and below, yeast activity decreases and stops.In any case, both high and low temperatures have a detrimental effect on the process and quality of the drink.

To reduce the intensity of foaming, you need to lower the temperature to 16-20 °C. This will normalize the process. It is possible to increase the total duration of fermentation, but the quality of the finished wine increases. It will taste better, will not be cloudy, and will acquire a beautiful color. Indicators such as transparency, viscosity, color and taste depend on the temperature at which fermentation occurred.

Restart fermentation

This method should only be used if the wort contains foreign types of yeast that strongly raise the foam. The cause can also be determined by the presence of an odor that is not released during normal fermentation, by the viscosity of the wort, or by an unpleasant aftertaste.

Measures to eliminate the problem: drain the juice from the sediment, heat to 65-70 °C (if possible, without air access) for 3-5 minutes. After cooling the heated liquid to 20-24 °C, pour it into the container again, add wine yeast or starter and install a water seal. Warming allows you to destroy unwanted microflora, and adding starter allows you to introduce the necessary microorganisms into the wort.

Intense foaming when making homemade wine is normal only if the layer does not exceed the specified height. If more foam is formed than necessary, then it is worth finding out the reason and starting to eliminate it.

Most often, the reason lies in incorrect conditions, so you need to adjust them. It is important to pay attention to the quality of the yeast; ideally, you need to use special wine yeast that properly regulates fermentation.Or carefully prepare the raw materials, wash the fruits and berries, sterilize the container and closure so that no fungi or yeast of undesirable species remain on them.