During the production of beer wort, a by-product with high nutritional value – spent grain – remains. Brewers do not utilize it, but sell it to livestock farms. Brewer's grains, used as feed for cattle, are a rich source of proteins; when regularly present in the diet, they normalize digestion and metabolism, increase the milk yield of dairy cows and the slaughter productivity of beef bulls.

What is brewer's grain?

Spent grain is a protein concentrate remaining after the production of beer wort.It is supplied to livestock farmers in silage and granulated form. The fresh product is a liquid that can be stored for no longer than 4 days. Then oxidation processes begin in it, useful substances are replaced by toxic ones. Therefore, for use in livestock farming, spent grain must be dried or ensiled.

From 3.5 tons of raw beer mass, approximately 1 ton of dry grain is obtained. It is sold in crumbly form or pressed into granules.

Spent grain is a valuable protein feed for cattle; 100 g contains:

- 78 g water;

- 4 g proteins;

- 2 g fat;

- 0.3 g sugars;

- 3.5 g fiber;

- 0.8 g of ash particles;

- 11 g of nitrogen-free organic matter;

- 0.1 g phosphorus;

- 0.07 g calcium.

The nutritional value of 1 kg of silage grains corresponds to a similar portion of feed for dairy cows with a protein content of 25% and an energy output for lactation of 6.7 MJ. Regular inclusion of spent grains in the diet in the amount of 10-12 kg per individual per day allows you to save 2.5 kg of concentrated feed per day.

A product rich in protein and fiber has a positive effect on cattle stomach. When regularly included in the diet, it normalizes the functioning of the rumen and prevents diarrhea in cows.

The nutritional value of the ensiled product is given in the table.

| Index | Value per 1 kg of dry mass |

| exchange energy, MJ | 11,4 |

| lactation energy, MJ | 6,7 |

| crude protein, g | 260 |

| protein undigested in the rumen, g | 160 |

| digested protein, g | 230 |

| rumen nitrogen balance, g | +5 |

Advantages and disadvantages

Instructions for use for cows

The consumption rate of beer product for a dairy cow is 5-10 kg per day, for fattened bulls and young animals – 10-15 kg. A portion of beer silage for cattle is selected individually, taking into account the quality composition of the main feed and the milk productivity of the animals. With an increase in the percentage of spent grains in the cattle diet, the total daily portion of feed is reduced. With the regular inclusion of a beer product in the diet of beef cows, the meat acquires a pleasant aroma and juicy taste.

Recommended portions of silage grains for cattle, taking into account milk production, are shown in the table.

| Cattle milk productivity, l | Daily portion of beer silage, kg |

| 15-20 | 2,5-3 |

| 20-30 | 4-5 |

| over 30 | 6-6,5 |

An approximate grass-silage diet for cattle, including spent grain:

- hay – 1 kg;

- legume and cereal silage – 15 kg;

- silage corn – 20 kg;

- spent grain – 10 kg;

- rapeseed meal – 1.5 kg.

Precautionary measures

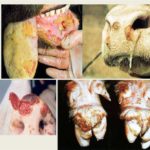

Improper use of beer silage can lead to serious digestive problems and death of cattle. The fresh product quickly becomes moldy, causing poisoning in the cows that eat it. Therefore, breweries try to sell waste within 24 hours, and farmers rush to feed or silage it.

Excessive inclusion of spent grain in the diet of cattle threatens stomach failure, obesity, and leads to reproductive problems.

Storage rules

Fresh beer waste contains 20-25% dry matter and has a temperature of 55-65 °C. With such indicators, the grain must be silaged within 3 days. Ensiling beer waste is more difficult than corn because it contains less moisture and sugars. The use of biopreservatives is useless, since at temperatures up to 65 °C lactic acid bacteria do not actively reproduce. The only acceptable and uncomplicated method of silage is storing it in polymer sleeves. If the use of sleeves is not possible, then you can place the grain on a concrete surface, cover it with film to create anaerobic conditions, and secure the structure with sandbags or other weights.

The silage heap should not come into contact with the ground. Ash particles contained in the ground disrupt fermentation processes.

It is advisable not to make silage heaps higher than 1.5 m. Ensilage lasts 3 days. After this time, the farmer can already depressurize the sleeve. But feeding silage from one sleeve cannot be extended longer than 3 days.

It is best to leave the silage in sealed conditions for a month. During this time, the core of the silage heap will cool to the outside temperature, and the proliferation of mold fungi will slow down.As a result, the product will be suitable for cattle consumption longer. Hermetically sealed silage bags can be stored for at least six months.