Physical activity and systematic hoof care are very important for cows. The stratum corneum grows, cracks appear into which dirt gets trapped, and inflammation can develop. The animal begins to limp and stops stepping on the affected leg. To avoid these problems, farms with many animals use special machines for processing cattle hooves.

Operating principle of the cow restraining machine

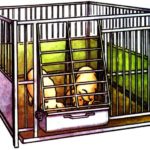

Cows are large animals that can easily injure humans.The machine allows you to process hooves, cut off horns, and conduct veterinary examinations without stress for the animal or danger for the farmer. A hoof stand is a stall with a frame into which the animal’s head is inserted; a wide belt is used to secure the cow under its belly; additional belts are used to secure the limbs in the position desired by the owner.

There are industrially manufactured machines. They are durable, metal, with wheels that allow you to move the structure, and an electric drive that can lift the back of the animal.

Advantages and disadvantages

The machine can be placed in a barn or in an open space. The structures are small, which allows for convenient placement of the device.

A simple product for securely securing animals can be made independently from wooden blocks, if the farm does not have too many livestock, the device will be inexpensive and will greatly facilitate the care of cows. A split made from metal pipes will be more durable.

Review of popular models

Mikulka hoof processing machines are Czech-made products. Excellent value for money and quality. The structures are mobile and easy to use. The Westfalia-Serge company presents a full range of equipment for farms specializing in keeping and breeding cattle. There are also convenient hoof trimming machines available. Specialists conduct master classes and offer after-sales service. Hoof processing machines "TOR" come from Austria. Comfortable and safe, it is possible to additionally equip them with weights, wheels for moving, and an electric lift for the rear limbs.

DIY making

You can make a stationary hoof trimming machine yourself. It is made from wood or metal pipes.

Materials and tools

Making a wooden machine is quite simple and cheap. To work you will need:

- wooden beams;

- boards;

- Boer;

- wood hacksaw;

- nails;

- chain;

- conveyor belt or leather belts.

You should select a flat area for installation of the structure.

Step-by-step production

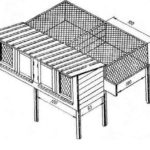

Pillars with a height of 1.8-1.7 meters are made from the bars - 4 pieces. You will need 2 more columns 0.7-0.5 meters high. Long posts are dug into the ground along the perimeter of the site, the size of which is 1.5 x 1.0 meters.

The pillars dug into the ground are fastened with boards. You need 2 longitudinal boards and one transverse one to fix the head.Small posts are secured behind the structure, and a strong crossbar is placed on them, on which the animal's leg will be placed when trimming the hooves. Chains with belts or a conveyor belt for convenient pickup are thrown onto the posts before the procedure.

To make the structure last longer, it is coated with drying oil or painted to protect it from dampness and rotting.

Rules for using the machine

The cow is driven inside the structure and immobilized with belts. Clean the hooves of dirt and remove the layer of growth with a sharp knife until the color appears white.

Important: you cannot carry out the procedure yourself if you lack experience, as it can cause serious harm to the animal.

The surface is leveled with a milling cutter, excess wool is removed with scissors, and sharp edges are ground off. After trimming, the hooves are treated with a 2% solution of copper sulfate or formaldehyde. They are placed in a container with a disinfectant solution for 10-15 minutes. Even the simplest hoof trimming machine simplifies the farmer’s work, because their animals should be trimmed systematically so that the cows do not suffer from orthopedic diseases.