Pumping honey from hives is a complex and time-consuming process. The quality of a valuable, medicinal product depends on the correctness of the beekeeper’s actions. To facilitate the procedure for extracting nectar from hives, beekeepers use various devices and designs. A table for printing honeycomb frames allows you to speed up the process of pumping out honey and, as a result, get a high-quality, clean product.

What is it needed for?

During the flowering period of honey plants, bees collect nectar and pollen.Next, the insects process them with a special secretion and place them in honeycomb cells. To obtain honey, insects seal the cells containing the delicacy with a seal consisting of wax, propolis and nectar.

As a result of this procedure, honey does not leak out of the cells, and chemical processes take place in the hermetically sealed honeycombs, as a result of which the delicacy matures to the desired condition.

To extract the finished beekeeping product from the honeycombs, the frames have to be printed. To do this, beekeepers have to cut off a thick layer of sticky and viscous bark.

In small apiaries, beekeepers use special knives or forks to print frames. But such tools are not suitable for a large volume of work, so it is necessary to equip the apiary with special designs. To make the task of pumping out honey easier, professional beekeepers use a special cutting table, which they purchase ready-made or make themselves from scrap materials.

The main purpose of the design is to hold the bee frames during the process of unsealing them and to collect the honey and wax extracted from them into separate compartments.

Important! Before starting work, the bee frames are heated to a temperature no higher than +36 degrees. In this case, the bar begins to melt, which facilitates the procedure of unsealing the cells with honey.

Types of tables

Humanity has been extracting honey for many millennia. During this period of time, people invented various devices for printing honey frames.

Modern beekeepers prefer special cutting tables and machines, which they purchase in stores or make themselves.

Cutting tables are of the following types:

- frames with honeycombs installed above a container for collecting wax;

- a table with a mesh that separates the nectar from the wax, equipped with a special container and a tap for collecting honey;

- machines for printing bee frames.

Important! The dimensions and equipment of the tables depend on the needs of the beekeeper; they can vary in length, width, volume of the basket for collecting wax and the size of the container for honey.

Advantages and disadvantages

Before purchasing or making a cutting table for printing frames, it is necessary to identify all the pros and cons of this design:

- stationary placement in a specific place, which does not require additional strengthening and fixation;

- maximum convenience for the beekeeper’s work;

- there is always room for additional tools and materials needed for work;

- If the cutting table is not efficient enough, you can always install an automatic or semi-automatic machine on the structure.

Important! When making a homemade table, the beekeeper takes into account only his own needs and convenience for work.

Drawings and dimensions

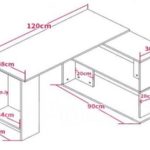

The dimensions of the structure for printing honeycombs are calculated individually, based on the specific needs of the beekeeper.

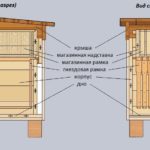

The table consists of the following elements:

- metal or wooden base, shaped like a regular table;

- A large container for collecting honey with a drain hole and an inclined bottom is fixed at the bottom of the table. Most often, a large washing machine tank or a stainless steel kitchen sink is used as a reservoir;

- a tap is installed in the drainage recess, which will be responsible for the timely drainage of nectar;

- a mesh with small cells is attached to the top of the container to collect wax;

- As holders for frames, a special removable stand made of slats is installed above the tank.

Important! The structure for printing honeycombs is made only from natural, environmentally friendly elements.

Tools and materials

To make your own design you will need:

- wooden or metal parts to create a table frame;

- a suitable container with a drain hole;

- a standard set of tools including a saw, pliers, screwdriver, hammer and nails.

You should also have additional wooden slats and a mesh with small cells on hand.

How to make a table for printing honeycomb frames with your own hands

When making a table for printing honeycomb frames, the beekeeper should rely on his own preferences and conveniences, which will increase work productivity.

Sequence of manufacturing the structure:

- markings are applied to metal or wooden blanks for the frame base;

- using a tool, a structure in the form of a table is made;

- Next, install a container for collecting honey with a drain hole and a tap;

- in the upper part of the container, a container for wax waste and a mesh for separating honey from the bar are fixed;

- A mount for a bee frame is installed above the tank, which can be made from ordinary wooden slats.

Advice! After expanding the apiary and purchasing an automated machine, the cutting table is not thrown away, but is used as a stand for new equipment.

Application

In beekeeping, a cutting table is used to hand-print frames containing bee nectar.

During the unsealing process, the wax falls into a designated container or onto a mesh attached to the honey collection tank. This procedure is done for each side of the bee frame.

After completion of the work, clean, tasty and aromatic honey is drained using a tap into prepared containers and sent for further processing or storage.