A winch for plowing land is a traction device that helps tow a cultivator or plow on a cable. The device is considered an excellent assistant in the garden. It greatly facilitates agricultural work. In addition, the device has many advantages in comparison with a manual cultivator or walk-behind tractor. Today there are many models of such devices on sale. They differ in size and configuration.

Winch design and functions

Agricultural winches are used to perform the following work:

- plowing the soil using the moldboard method;

- hilling up plantings;

- planting and digging potatoes;

- horizontal movement of goods.

The operation of the winch has certain features. First, the impulse is transmitted from the engine to the pulling rope, and then to the plow or cultivator. Thus, the tool clings to the rope and moves due to the force of the winch motor. This helps save time and effort on plowing.

To operate this type of device, 2 people are needed. One must control the plow, and the second must control the operation of the winch itself.

The device not only facilitates agricultural work, but also has other advantages:

- The use of the product helps to perform plowing more efficiently. It provides deep loosening of the soil. As a result, there is practically no weed left in the soil.

- With the help of the device it is possible to maintain soil fertility.

- The winch does not pose a danger to plants. When planting and digging up potatoes, the tubers are not damaged, as is the case when using a walk-behind tractor. This is due to easier control of the direction of the plow or hiller.

- The device is small in size and versatile. It can be used in open ground and in greenhouse conditions.

- The device is characterized by ease of use and repair.

- The winch does not pose a danger to the environment, which cannot be said about the use of tractors and walk-behind tractors.

Types of winch

Depending on the type of engine, the devices have the following varieties:

- electrical - their power parameters are approximately 1.5 kilowatts;

- gasoline - the power indicators of such products, on average, reach 6.5 horsepower.

Depending on the type of control, winches can have the following types:

- manual - buttons and levers are used to control them;

- with foot drive - most often used for gasoline engines.

Popular models

There are many types of effective devices on the market today. They differ in functionality and operating principle.

ML-03 “CELINA” with KPO

This is a Russian device, which is distinguished by a carefully thought-out package. The winch is mounted on a durable metal frame. Its base is complemented by powerful teeth. They go deep into the ground and reliably fix the position of the device. To increase durability, the device is equipped with a platform on which you can stand with your feet.

"Mogilev" LS-100A

This “bull” is suitable for summer residents who have small plots. To use it, it is enough to place the device at the edge of the dacha and connect the plow to it. The product is even equipped with wheels for transportation. The winch is characterized by an electric drive, so it must be connected to a household network.

ML-1 M "Bull"

The advantage of this device is its universal purpose. It depends on the type of attachment used. The device can be used for plowing and hilling areas. It is also suitable for moving heavy objects and cutting wood.

ML-2M "BYCHOK-2" ("Krepysh")

This winch is small in size and high in power. The kit may or may not include attachments. The device is characterized by a long cable measuring 50 meters. In addition, it is highly productive.

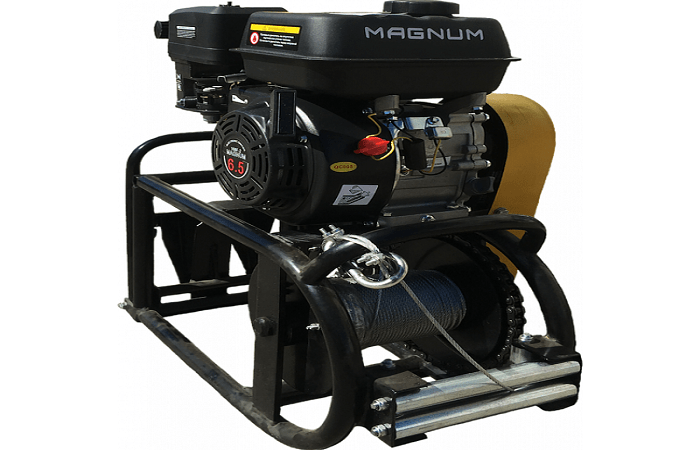

"BARS" (BURLAK) ML

This model is powered by a carburetor engine and is air-cooled. The device is characterized by an engine power of 6.5 horsepower. The kit also includes attachments. The device can be controlled using a foot drive and a manual starter.

"Bull" ML-1RX

This winch has a compact size and high productivity. It is characterized by a gasoline engine with a power of 6.5 horsepower and a two-speed transmission. The device can be controlled using the clutch pedal, shutdown button and adjustment lever.

"Mogilev" LS-200

This is an improved model of the LS-100A winch. It is characterized by increased power, which is 1.7 kilowatts. The weight of the product is 49.3 kilograms. The device is a high-performance winch that requires connection to an electrical outlet. The advantages of the product include reliability and ease of use.

"Boomerang" 2000

This is one of the most popular Russian winches, which has small dimensions and weight. The latter figure does not exceed 35 kilograms. A welded frame is used as a frame. It houses a drum with a traction rope, an engine and other mechanisms. Engine power parameters reach 2.5 kilowatts.

Selection factors

In order for the winch to serve as long as possible and perform the necessary functions, when purchasing a device you should consider the following parameters:

- Motor type – when electrifying a site, it is best to buy an electrically driven winch. This option is considered more economical.

- Engine power - it affects the speed of movement of the cable and the productivity of the product.

- Rope stiffness and diameter – it is important that the tension rope is rigid and elastic.It will help bear the load during work.

- Ease of Control – Electrical appliances are the easiest to control. However, new models of gasoline devices are also optimized for ease of use.

- Contents – Most models come with the minimum required tools.

- Dimensions – it is important that the winch can be easily transported on site.

Do-it-yourself electric winch plow

You can make an electric winch with your own hands. It is permissible to use a worm gear as a basis.

To manufacture the product you need to do the following:

- Make a coupling to separate the gearbox shaft from the drum shaft. This will help unwind the cable to the desired length.

- Make a drum for winding the cable.

- Make a housing for the unit.

- Secure all elements with corners.

Preparing for work

At the stage of preparation for work, at the beginning of the row, you need to install a winch by driving in 2 metal fixing rods. Unwind the cable to the required length. Then you need to connect the 2 shafts with the hub and turn on the grinder. This will start the device.