After a period of active care for bee colonies and providing them with the necessary nutrition for reproduction, the time comes to collect honey. If the apiary is large, then it is advisable for the beekeeper to use special devices. Some of them are made at home. A do-it-yourself honey extractor is an indispensable device that is used when collecting product.

What it is

A honey extractor is a small unit that is used to pump out honey.Of course, you can do without it if the apiary is small, but for a large farm it is necessary. A honey extractor is often purchased at a specialized store, but some beekeepers make it themselves, using scrap materials and drawings.

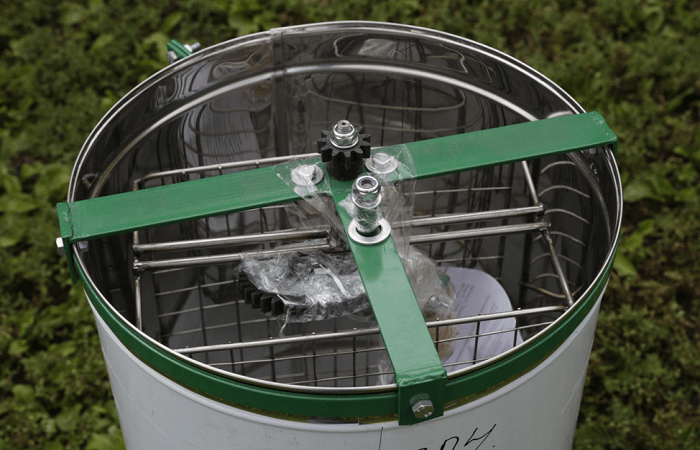

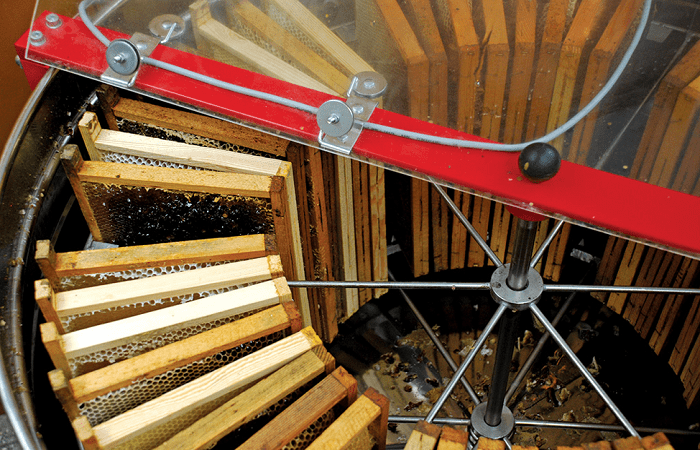

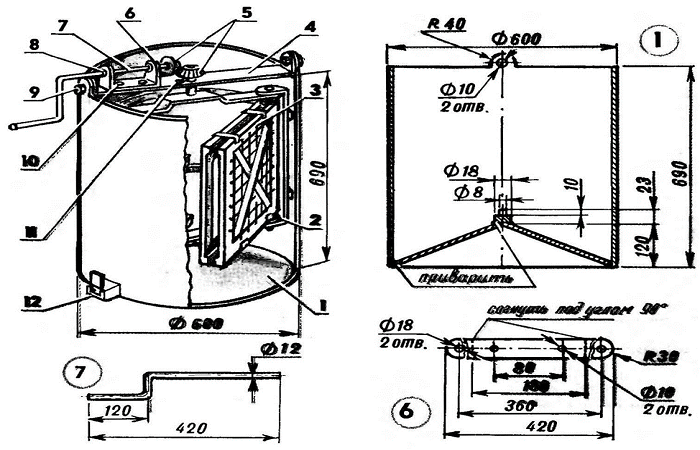

The design of the device is represented by a cylindrical container, inside of which vertical cassettes with honeycombs rotate. At the bottom there is a tray where honey is collected.

The advantages of the unit are obvious: with its help, honey collection occurs much faster, in addition, the honeycombs remain intact, so they can be reused.

Principle of operation

Honey extractors are made from various materials, but the principle of operation is always the same. The operation of the device is based on centrifugal force, which is provided by a cylindrical container. The honeycombs are printed out with a knife and placed in cassettes. When the drum moves with acceleration, centrifugal force arises, honey flies off onto the walls of the unit and then flows down. For this purpose, special holes and a container for collecting honey are provided.

Inside the honey extractor there is a drive that rotates the rotor, frames and cassettes. The drive can be electric, manual or foot driven. The number of frames inside the honey extractor varies. It depends on the volume of production. Some designs are designed for several frames, but there are units that can hold up to 50 pieces.

After the honey is completely pumped out, the frames are returned to their place in the hives, where the insects again begin to pump them with the product. If there is no bribe, then the bees will need time to build up the honeycomb again. Under such conditions, the beekeeper loses not only time, but also money.

Manufacturing options

There are two types of devices - radial and chordial honey extractor.In the radial frame with honeycombs, they are placed along the radius, and the chordial one is distinguished by the fastening of the frames, which are located along the inner surface of the container.

One of the criteria that determines the type of design is the drive. If the apiary is small, then a manual drive is quite suitable. It is important to consider that when installing an electric motor, you will need a device that can control the number of revolutions. Sometimes at too high speeds the device breaks the frames, and this leads to losses. The manual drive allows you to independently control the speed and revolutions.

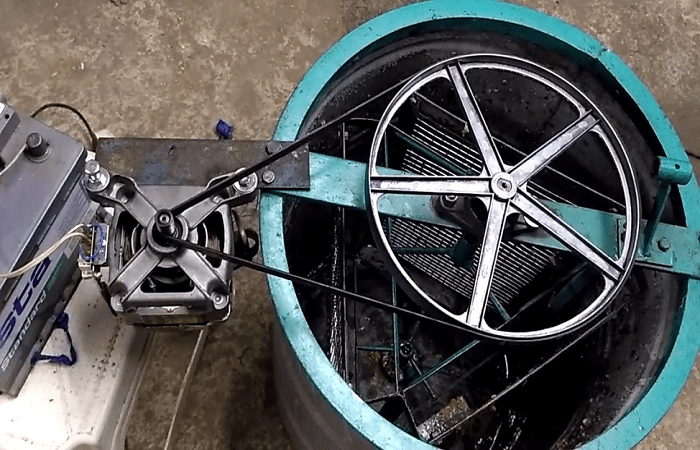

Electrically driven

In designs where an electric drive is provided, the rotation of the container occurs due to the electrical network or battery, which is convenient when pumping honey into the field. Electric honey extractors are ideal for apiaries that produce tons of product. The speed and direction of rotation can be controlled, but there is a drawback - the device is quite difficult to maintain.

Without electric drive

If the design is made without an electric drive, the drum rotates manually. This option is considered traditional, since this is what many beekeepers use. The honey extractor does not depend on a power source; it can be used in any conditions. Another advantage of the design is its low cost. Among the disadvantages, users note the low pumping speed. However, this is not so important if the beekeeper has only a few hives.

Sizing

When making a honey extractor, you need to focus on the drawings. The dimensions of the device depend on the total number of frames. For a small apiary, a device designed for two frames is sufficient. Accordingly, if honey is produced on a large scale, you will need a unit that can accommodate several dozen frames.

What materials can be used

Making a honey extractor with your own hands from available materials requires careful selection of materials. Resistance to moisture and admissibility of contact with food are important. Most often, wood or plywood, plastic, aluminum or stainless steel are used as the basis. The most expensive material is stainless steel, however, along with this, it is also the highest quality.

Regardless of what material is taken as a basis, you will need to prepare additional elements:

- fittings;

- axis;

- bearing;

- belt;

- pulley;

- silicone sealant;

- mesh or wire for cassettes;

- tap for draining the product and a nut for fixing it;

- bracket;

- rotor;

- rheostat;

- electric motor for drive.

The tools you need to prepare are a jigsaw, a circular saw, a screwdriver or drill, self-tapping screws, as well as nails, and a hammer. These tools are essential for working with wood. If plastic or aluminum is used as the main material, you will need a grinder, a hacksaw, and a soldering iron.

How to make a honey extractor with your own hands

The device execution algorithm and features depend on the selected material.

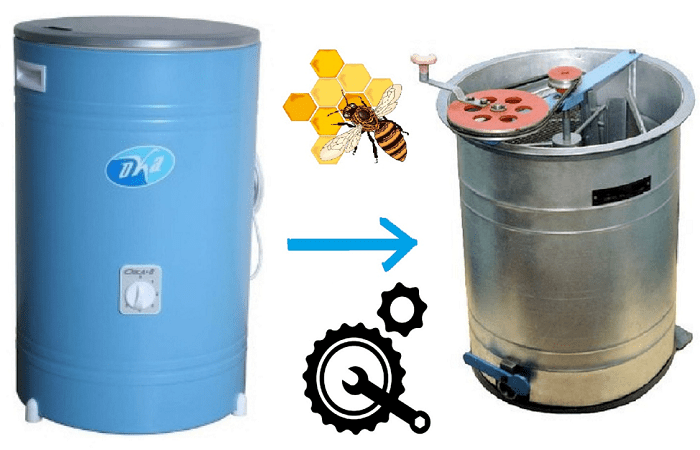

From the washing machine

The drum from the washing machine is universal. In combination with a body made of a similar material, it makes it possible to make a durable, high-quality honey extractor.You can use two drums - the larger one is recommended to be used as the body of the device.

The execution algorithm is as follows:

- Cut off the bottom of the smaller drum.

- Install it into the housing.

- Weld several metal rods to the bottom from the inside. Weld their ends to the bearing.

- Insert an axle of a suitable size and diameter into the bearing. Secure with self-tapping screws.

- Attach a pulley to the top of the axle, attach a handle and secure the connection with a belt.

Made of wood

To make a wooden honey extractor at home, any wood is suitable, the main condition is that it should not contain resin. Only dry material is needed.

It is recommended to make the drum in the shape of an octagon. A rotor should be installed inside it, as well as fastenings for the frames. For the side wall you will need a solid board. A hole with a diameter of 20 mm is required at the bottom of the structure. You can attach a tap or make a plug with a seal.

Plywood

From plywood you can make a homemade small device that is suitable for a small farm. The honey extractor will be light but durable. This option is ideal for frequent transportation. In addition, the manufacturing process of the device is simple.

The thickness of the plywood should be no more than 10 mm.Otherwise, the manufacturing process is no different from a wooden honey extractor. The inner surface must be thoroughly treated with wax, preferably applying 2-3 layers. Fasten the structure with nails or glue suitable for wood. To ensure strength, tighten the side panels with a metal hoop at the final stage.

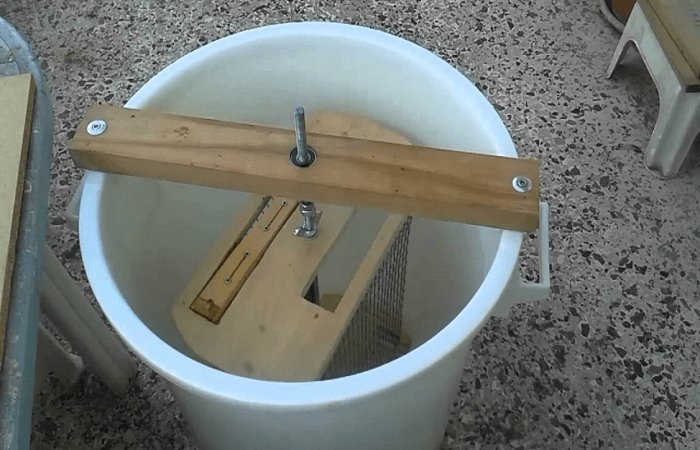

From a plastic barrel

The plastic barrel design is a suitable option for beginners. The plastic chosen for the design must be food grade. It does not corrode, does not absorb odors, and is resistant to mechanical stress. Another advantage of plastic is that maintenance is simple and will not cause any difficulties.

Of course, some additional elements will be required during manufacturing, such as metal rods, boards and a rotary structure. For the rotational element, pedals from a bicycle or a sewing machine are used. Rotating the pedals causes honey to flow down the walls of the device.