Making a homemade honey extractor from an automatic washing machine is not so difficult. Many beekeepers are thinking about creating a mechanized unit for pumping out honey. Especially those who are going to put the business on stream and sell the fruits of their own labor. Factory-produced finished products are reliable but expensive. The solution is to assemble a honey extractor using non-working household appliances.

Types of honey extractors

Most existing designs are easy to manufacture. They do not require special knowledge, skills or complex tools.

At the initial stage, you should make a choice which material will be used to create a honey extractor. They are as follows:

- Tree. The most common design. Any suitable container will do. An oak barrel, for example.

- Aluminum. It is also quite often used on the farm. A boiler with a large capacity tank is suitable. Or a saucepan.

- Stainless steel. This is a bit more complicated. To prevent the future honey extractor from leaking and to serve for a long time, it is necessary to connect the sheets by welding. Or use a ready-made solution - a tank from an old activator-type washing machine.

- Plastic. Modern plastics are not much inferior to metal in terms of strength and wear resistance. The capacity from the “Malyutka”, a small-sized washing machine, will be just right. Another suitable size polymer tank will do. The main thing is that the thickness of the walls guarantees structural rigidity and stability.

Which option to choose is up to you. If only the future honey extractor would justify the investment and costs, with minimal modifications to the finished tank. And without the use of complex technical solutions.

The limits on the size of the honey extractor are set by the designer himself. The key indicator here is the dimensions of the frames. Cassettes are installed in the tank, where frames with honeycombs are fixed. The fastening should be simple but effective. Next, the design of the honey extractor will be analyzed in detail.

Let's focus on types for now. There are 2 of them:

- radial;

- chordial.

The operating principle of the honey extractor is simple and clear. The tank with frames rotates using an electric, manual drive. Centrifugal force squeezes honey out of the honeycomb, then the finished product flows into the lower part, where a drain tap is provided. Most often, radial honey extractors are used in home-made solutions.

Necessary tools, materials

Depending on the chosen honey extractor design and capabilities, a list of materials and tools is determined. You will definitely need:

Bench hammer (small sledgehammer)

- Vise.

- Drill (hand, electric, screwdriver).

- Angle grinder (grinder).

- Welding transformer.

- Electric soldering iron.

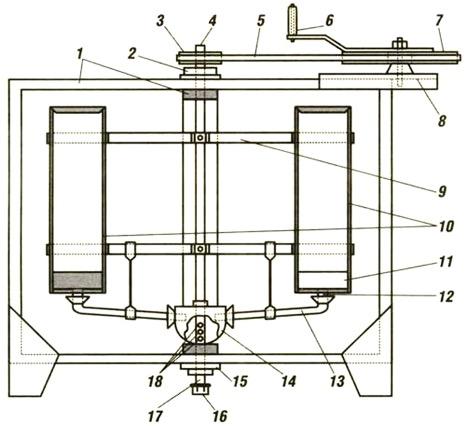

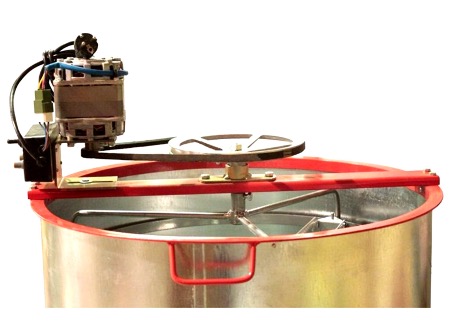

Here is a basic set of tools. It can be supplemented or trimmed. The materials you will need are steel plates, rods, as well as equipment consumables (cutting wheels, electrodes, drills, solder). An approximate view of a finished honey extractor with an electric drive and a control unit is shown in the figure.

And the videos will help you understand the operating principle and structure of the unit:

Drawings and dimensions

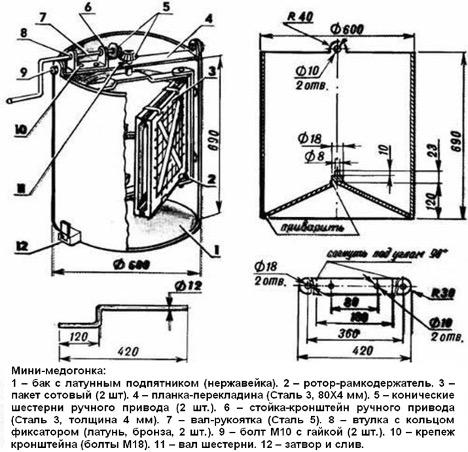

The following are the typical dimensions of a homemade honey extractor. The drawings show approximate dimensions, which can be adjusted to suit the manufacturer's needs.

The following drawing shows the detailed structure of the unit, indicating the components.

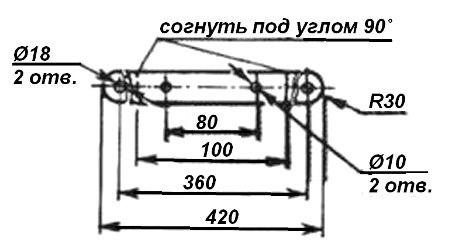

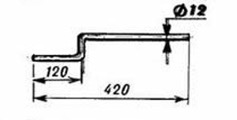

Detail drawings show enlarged views of individual components.

Crossbars

Rotor bars

Now you almost know how to make a honey extractor. There are a few details left, a description, and tips for making a unit from an old washing machine. The age-old question: whether to choose a manual or electrified design remains open. Both options have certain advantages. Well, and the disadvantages, as without them.

Manual drive is simpler and more reliable. Allows you to adjust the spin speed. The electrified solution provides greater productivity. This means the yield of the final product, honey. The complicated design involves the installation of a control unit. This unit provides spin adjustment and eliminates the need to control the process.

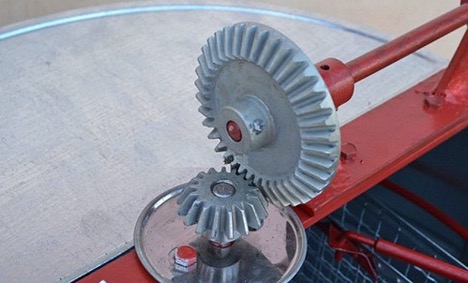

And these are bevel gears

Making a honey extractor from a washing machine

Creating a unit from improvised means at minimal cost is an excellent solution for a novice beekeeper. And making a honey extractor with your own hands is not so difficult. You need a non-working (unnecessary) washing machine with a ready-made tank of a suitable size. Models “Siberia”, “Alma-Ata”, etc. are suitable. The age of the “semi-finished product”, the washing machine, does not matter.

The tank of the machine has fairly thick walls and is almost not subject to wear. It remains to modify the capacity. Close all unused openings so that they do not leak. Brew (you need a welding machine), seal with plugs, linings, and solder.

Understanding the design of a honey extractor is not difficult. Anyone who has at least a secondary education and knows how to work with metal can do this.

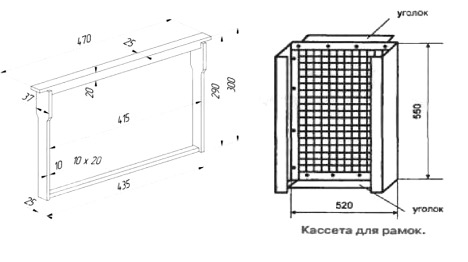

Cassette

Standard, generally accepted sizes of cassettes depend on the hives used. That is, it needs to be adjusted locally. The typical aspect ratio is 435x300 mm.

Typically, finished cabinet frames are slightly smaller. When making cassettes manually, it is advisable to use stainless steel. This is an inert material that cannot be oxidized and does not affect the quality of honey. Which assembly method to use - welding, bolting - is up to you. Stainless steel is not a widely available material. But it’s worth trying to ensure everything is as it should be. Replacing with “rust” or ordinary steel is not advisable.

The figure shows a structure made from a corner and tensioned wire.

Drive unit

The issue of the presence of a drive in the design is a subject of debate among beekeepers. On the one hand, the manual method determines the spin speed.And not so traumatic for the frames. After all, they are always reused. On the other hand, the electric motor frees you from the need to constantly monitor the process. Waste time.

If you choose the electric option, you should get a motor. Modern engines provide high speeds, are compact, and efficient. But you need to adjust the speed. For this, a simple belt drive is used, plus a pair of pulleys of different diameters. A smaller disk is mounted on the motor axis. On the axis of the tank - larger. In the manual version it’s the other way around. The diameter ratio is selected experimentally. Automation, the control unit will allow you to control the speed within acceptable limits, making honey extraction a common thing.

Stand for honey extractor

To decouple the unit from the base, a stand is needed. It will ensure stable operation of the honey extractor and reduce the noise level. In addition, the installation must be located at some elevation so that a container can be placed to drain the product.

The best option is to make 3 legs around the perimeter of the honey extractor. They can be attached by welding or bolting. The main thing is that the seal is not broken. And the honey did not flow out of the container and was not wasted. A welded stand or frame made to the dimensions of the device is suitable.

The issue of painting remains controversial. The finished product must not contain any impurities. And under no circumstances be dangerous to humans.However, external surfaces can be coated with modern, safe, non-toxic paints and varnishes.