The main task of beekeepers is to timely extract finished honey from the hives. If in small apiaries this procedure is carried out manually, then in large beekeeping farms the process is automated with honey extractors. The most common type of honey extractor is called rotary, and the electric drive for such equipment can be made with your own hands. We will look into the details below to see what is needed to make the equipment.

Principle of operation

Pumping out ripe nectar from honeycomb frames is a long and labor-intensive process.If honey extraction is carried out manually, then each frame has to be printed on both sides with a special knife or fork, and only then the sweet bee product is drained from it. When using special equipment, the process of pumping honey is greatly facilitated and reduced in time.

At its core, a honey extractor is a metal tank into which frames filled with honey are placed. Next, the centrifuge spins, the honeycombs are unsealed under the influence of centrifugal force, and honey flows freely from them.

Honey extractors vary depending on the number of honeycombs placed in them. To fully automate the process of pumping out honey, an electric drive with an additional unit that regulates the rotation speed of the centrifuge is installed to operate the honey extractor.

Interesting! Honey pumped out of honeycomb frames using a honey extractor is called centrifugal.

Varieties

An electric drive for a centrifuge can be purchased at specialized stores or made independently. The task of such equipment is to create a torque sufficient to bring the honey extractor into working condition.

The main part of the drive is the motor, which can vary in power and design. The following designs are suitable for the manufacture of the drive:

- motor from car wipers;

- washing machine motor;

- motor from an electric bicycle;

- power tools;

- generator or batteries.

Advantages of using an electric drive for honey extractors:

- full control of the centrifuge rotation speed;

- rotation direction switch;

- control of honey extractor rotation time;

- significant reduction in time and labor costs when pumping out honey;

- with automated pumping of nectar, its quantity increases and the quality of the beekeeping product improves.

Important! All types of presented engines operate from electrical networks with a load of 220 volts, 12 volt batteries or solar panels.

Manufacturing

When manufacturing a drive for a centrifuge, care must be taken, because the work is carried out using electrical voltage.

- When choosing parts for the unit, it is necessary to purchase only high-quality materials, first inspecting them for damage.

- The drive assembly is carried out strictly according to the instructions; if possible, it is better to get help and support from a specialist.

- Work on assembling the structure is carried out in a place away from children and pets.

Once the motor for the centrifuge has been selected, you can begin manufacturing the drive.

- The main design detail is a properly selected engine.

- Next, it is connected to the gearbox; for this, a special part in the form of a board is used.

- The half-coupling is used to connect the drive to the gear axle.

- The rotating parts are connected by a clutch to the drive axle.

- One side is rigidly attached to the axle, the other is connected to the main axis of the motor.

Advice! For proper operation of the drive, it is best to use a translator that generates a normal 220 volt network load.

Materials and tools

To make an electric drive for a honey extractor you will need:

- a belt made of elastic, stretchy material, you can use a part from washing machines;

- generator type G108 or G21;

- pulleys;

- fastenings;

- switch with timer;

- pliers;

- hammer;

- triangular and round files;

- electric drill;

- adjustable wrench

- wrenches of different sizes;

- spring of appropriate size for the electric drive.

Important! If you have the necessary tools and diagrams, even a novice beekeeper can handle making an electric drive for a honey extractor.

Scheme

Assembling an electric honey extractor with your own hands is not difficult if you carry out the work according to the following scheme:

- remove the lid from the tank;

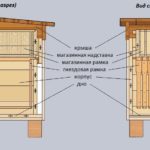

- using a tool, a tank with a removable lid and two bearings is made;

- a thread and groove are cut on the axis located next to the bearing;

- at the other end of the bearing there is a bushing that is fastened to the rotor;

- to secure the bearing to the container lid, use a metal plate;

- Next, the selected and prepared motor is attached to the honey extractor body with clamps.

Inside the honey extractor body there is a centrifuge and a drum with cassettes for placing honeycomb frames.

Assembly

To assemble and start the electric drive for the centrifuge, you must perform the following steps:

- remove the existing drive from the structure;

- in the large pulley it is necessary to drill a hole corresponding to the main shaft of the centrifuge;

- Install the finished pulley on the upper part of the shaft;

- a suitable pin must be secured to the top plate with the gearbox;

- then install the generator;

- a hole is made in a small pulley corresponding to the diameter of the shaft and secured to the generator;

- the assembled generator is securely mounted on a prepared stud and connected to a voltage of 12 volts;

- using a round file, make a groove on the pulley no more than 8 mm deep;

- then use a triangular file and bring the groove into a wedge shape;

- the elastic belt is placed over the pulleys and tensioned using a spring;

- ground and the corresponding motor terminal are connected to the timer switch; to optimize operation, one of the motor terminals is connected, skipping one of the sections of the resistance block.

Important! You can adjust the direction of movement of the honey extractor using a belt. If you remove it and put it back in a figure eight, the direction of movement of the centrifuge will change to the opposite.

Ready solutions

In specialized stores you can purchase honey extractors of various designs and power with an electric control unit. Such designs are created specifically for operation in difficult conditions and are characterized by reliability, high performance and resistance to various climatic and weather conditions.

If purchasing a honey extractor is not part of the beekeeper’s plans, you can purchase a separate electric drive and install it on a homemade structure.

Usage

To pump out healing and tasty nectar from bee frames, an electric honey extractor takes 3 to 5 minutes. To easily drain the nectar, the unit is installed on a wooden cross, and after finishing the work, open the tap and pour the honey into the prepared container.