Bees collect honey on special frames installed in hives. Beekeepers make them for them from wooden blocks. For a home apiary, having a conductor for assembling frames will allow you to make them in the required quantity in a short time. Let's look at the types of construction sets, how to assemble them with your own hands at home, what materials and tools are needed.

Why do you need a conductor for collecting frames?

This is a special device, simple in design, which greatly simplifies and speeds up the assembly of standard frames.This is because they are assembled in several copies at once, creating a kind of conveyor belt. As a result, a person spends less time and effort collecting products necessary for beekeeping.

For a small apiary, it is enough to have 1-2 devices on the farm. The standard one is designed for approximately 10 copies. It can be used many times. You can purchase a ready-made conductor or make it yourself.

Types of machines

The conductor can be made of square metal tubes or wooden blocks. The design of the device is simple and reliable, it can be adjusted to produce frames of various types. Usually these are the universally used frames “Dadan”, “Rue” and “Shop”.

Drawings and dimensions

The height of the jig is adjusted depending on the size of the frames being knocked down on it. For “Dadanovsky” ones the height will be 300 mm, for “Rutovsky” ones – 230 mm and “magazine” ones – 15 mm. The designer can be disassembled and folded into separate parts if you need to move or transport it somewhere.

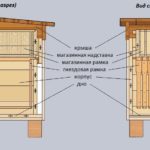

The constructor consists of four tubes or bars, fastened together in the shape of a square. The height of the wall of the structure is 130 mm. For 10 products, the internal space should be like this:

- length 435 mm;

- width 373 mm (the width of each strip is 37 mm and 3 mm should be left for a gap that will ensure the free fit of products).

In the side walls of the structure there are wooden grooves into which holder bars are inserted.

The distance between them and the walls of the structure should be equal to the thickness of the side frame walls. Ten such grooves must be made from wooden blanks and installed on opposite sides of the conductor. They must be installed tightly so that they do not dangle.

Preparation of tools and materials

You will need a metal tube or wooden blocks, depending on which conductor you need to assemble.

How to make a jig for assembling frames with your own hands

The procedure for manufacturing a metal conductor:

- Prepare metal profile parts, cut to the dimensions indicated above.

- Weld the strips at the joints.

- On both sides in the lower part, weld stops at the bottom, also cut from a pipe, which will align the wooden planks during assembly.

- At the corners from the outside, screw the bolts that will adjust the length of the frames.

The wooden jig is assembled in the same way. Wooden planks are attached with screws along the edges. You need to make grooves in two opposite sides of the device. Like a metal one, a wooden construction set can be adjusted depending on the dimensions of the products. It can produce, on average, a dozen blanks at a time. Due to the fact that the frame slats that are knocked down are level, when finished they turn out to be the same size. They are easy to install in beehives and honey extractors.

Assembling blanks on the jig is just as easy:

- You need to place it on a flat surface.

- Place the sides of the frames vertically on both sides.

- Secure them at the bottom with clamping spacers.

- Spread the sidewalls along the end with glue, place the top strips so that they connect the sidewalls on opposite sides of the jig. Secure the joints with nails, small screws or a stapler.

- To continue working and assemble the remaining parts of the frames, you need to turn the jig over with the top strips down.

- Install supporting side panels on the fixing parts of the conductor. Apply glue to the ends of the side panels again.

- Lay out the planks sequentially and also secure them with a stapler or nails in the corners.

- Remove clamp spacers, support strips and clamps.

You can remove finished products from the structure. Assembly time is 10-20 minutes, which is significantly less than if you assemble each frame separately.

If the farm has a jig for frames, they can always be quickly assembled from wooden planks of a suitable size. The device is simple, easy to use, and saves time and effort.