An adjustable apiary trolley is a necessary design for an apiary. Every beekeeper knows how hard it is to care for bees. To increase the productivity of the apiary and reduce labor costs, you should make a small cart for transporting hives. Its design is simple and looks like a metal frame. Having the drawings, the beekeeper will be able to make it himself.

What are bee carts?

A trolley for transporting hives is a small-sized metal lift.It should be light, but withstand the heavy weight of the hives. As a rule, the design consists of the following parts:

- two frames (one of them must be stationary);

- two wheels;

- fork;

- cable;

- lever arm;

- adjusting screw;

- installation holes;

- clamp bracket.

The operating principle is simple enough for the beekeeper to easily operate the wheelbarrow. To load, you need to drive the cart with the lever raised to the hive.

The bracket with the screw should be moved to a position in which the distance between it and the hive is no more than 5 mm. Next, the handle must be lowered down, then the hive will be clamped. The load is lifted to the required height using a winch.

Types of trolley lifts

There are two main types of trolleys - mechanical and manual. The choice depends on the size of the apiary, as well as on the daily workload of the beekeeper. The manual drive is suitable for a small apiary and small hives. They are generally not heavy, so raising or lowering the hive will require some effort.

If the apiary area is vast, then it makes sense to get a mechanically driven trolley, since it will reduce the physical load on the beekeeper. This design will ensure the transportation of hives with significant dimensions.

Requirements and standard drawings

Standard trolleys have certain requirements:

- maximum cargo weight: 120 kg;

- the ability to transport hives up to 1100 mm high;

- stainless steel frame;

- wheels with high-quality all-terrain tires;

- strong, securely fortified platform;

- clamps on top and bottom.

When choosing a trolley model in a specialized store or making it yourself according to drawings, it is important to carefully consider every detail.The cart must be strong and reliable, because, most likely, the hives will have to be transported over rough terrain.

Everything must be done to eliminate the slightest possibility of the bee colony falling.

Required tools and materials

If your plans include building a cart yourself, you should prepare the necessary materials and tools in advance. You need to take care of the following materials:

- square pipes for professional use;

- wheels;

- stainless steel rod;

- two types of bolts;

- nuts for fastening;

- durable cable;

- winding reel;

- roller and bearings;

- spring.

You will need some tools, for example, a drill, a screwdriver, a tape measure, a hammer, and metal cutters. You also need to prepare a welding machine and protective gloves with special glasses.

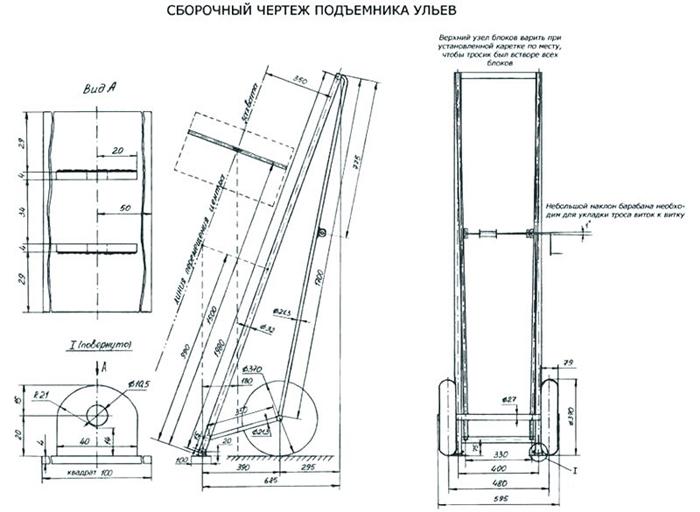

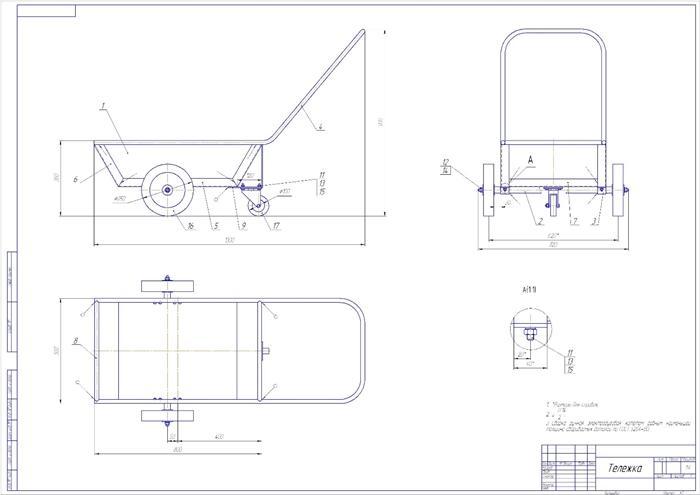

Step-by-step assembly instructions

The trolley should be assembled sequentially, focusing on the drawings. Do not neglect minor details, as they affect the strength and stability of the structure. Before starting work, you need to double check the materials and tools.

Frame assembly

You need to start with the frame, because this is the simplest design. First you need to take measurements. Then proceed in the following sequence:

- The frame is made from square pipes. The result should be four cross beams that are butt welded.

- Weld the lowest beam to the sidewalls. For the top and bottom beams, use the same size pipe as for the frame. Medium beams will require a smaller pipe.

- Fix the second beam on top at a distance of 50 cm from the top one. Weld the second beam from the bottom at a distance of 38 cm from the bottom.

- Make a cut along the entire length of the posts from the outside to move the bearing. 2 cm will be enough. In this cut, install M6 bolts at the top and bottom. They will prevent the bearing from flying out of the groove.

- On the third beam, on both sides, make side holes for attaching wheels. Weld the handles at a distance of 20 cm from the top edge of the frame to the side pipes.

Next, you can proceed to installing the lifting mechanism.

Installing the reel, lifting mechanism and wheels

The installation algorithm is as follows:

- Attach a bearing with a lock to the front part of the upper tube, which will prevent the cable from falling out. Place the cable in the ditch. Secure the free upper end on the left side.

- Attach the coil to the second beam. When the carriage is lifted, the cable will be wound onto the reel. Install the axle in the bearing. Weld the lever on the opposite side.

- Connect the lever handle with a cable to a metal tongue and a spring. The tongue will act as a fuse.

The wheel axles should be secured with brackets and secured with nuts on the outside.

Mounting the carriage, fork and clamps

The lifting part of the trolley, or carriage, is the most complex part. First you need to make the frame of the carriage, leaving space for the clamps. They will be held in place by hinges. When the hinge tilts under the influence of traction, the square begins to warp, which pulls the side hinge tube along with it.

The tilt of the hinge is adjusted by a bolt with a spring. The degree of compression of the clamps depends on the deflection of the hinges. Clamps are also made from pipe. It is important to provide clamp forks for gripping.

A block for the cable is welded in the center of the lower transverse pipe of the lifting part. The movement of the carriage along the frame is possible due to four bearings, which are located on the side posts of the lifting structure.

At the bottom of the carriage, it is important to secure the pipe sections on both sides with M6 bolts, into which the forks are then inserted. To achieve compression of the carriage mechanism, it is necessary to actuate it using a lever with a rod.