Many beekeepers make a wax press, or apiary press, with their own hands, since they take into account the volume of honey that their apiary produces. There are several types of equipment, but they all have the same operating principle. The wax press is simple to use and is an important element in every apiary. It allows you to simplify honey procurement and increase profits.

What it is

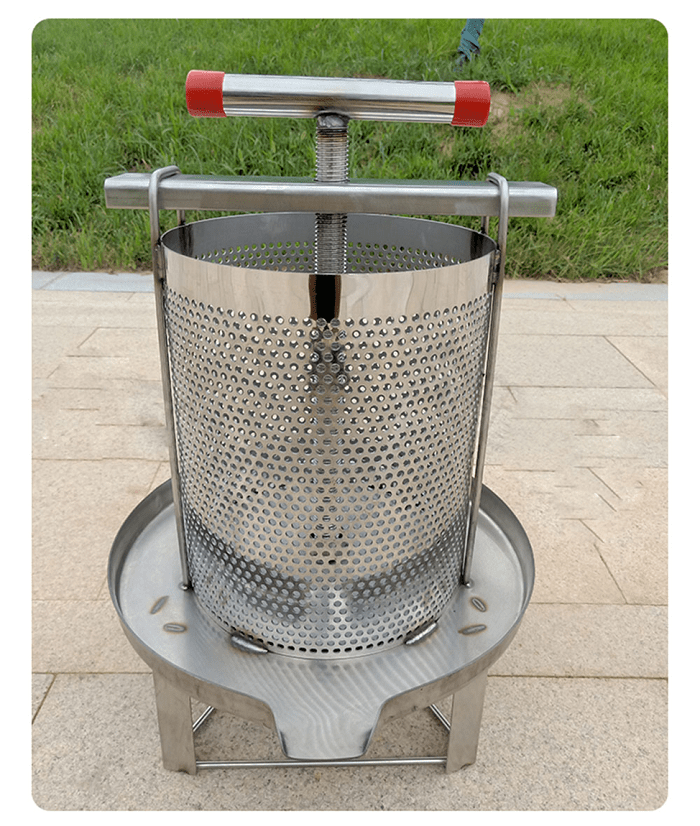

A wax press is a device used to squeeze wax out of honeycombs. The device allows for spinning for subsequent processing and sale. In this case, the wax comes out clean, without foreign impurities.

A wax press for squeezing, regardless of the type of design, at the beginning of work brings the raw material to a certain temperature, after which it is immersed in a special compartment for subsequent pressing. Under the influence of a centrifuge, the liquid fraction of the feedstock is processed. Clean wax flows through a gutter or through holes into a prepared container.

After the procedure, the remaining components are removed from the equipment. The mechanism parts must be thoroughly washed and dried.

Advantages and disadvantages

Using a press made by yourself for squeezing is completely justified due to the following advantages:

- high performance;

- obtaining a pure product of excellent quality;

- cost savings;

- lightness and compactness of the device;

- simplicity during operation.

There are also possible disadvantages, which beekeepers include the laboriousness of the heating process. They note that it is not easy to withstand high temperatures in a mortar. In addition, not everyone can make equipment. You need to have the necessary skills and understand a little about drawings. It is also necessary to purchase structural parts.

Types and models

There are several types of device:

- Kulakov's apparatus. The design is a cross between a manual device and an industrial one. It can be used at home.

- Manual device. It is appreciated by owners of small apiaries and novice beekeepers. It is small in size, up to 40 liters in volume, and the cost is low. Disadvantages include manual heating and not very high-quality cleaning.

- Industrial type device. It is not possible to make such a device at home.

To make a wax press yourself, use drawings of a hand-held device or a Kulakov apparatus.

Required tools and materials

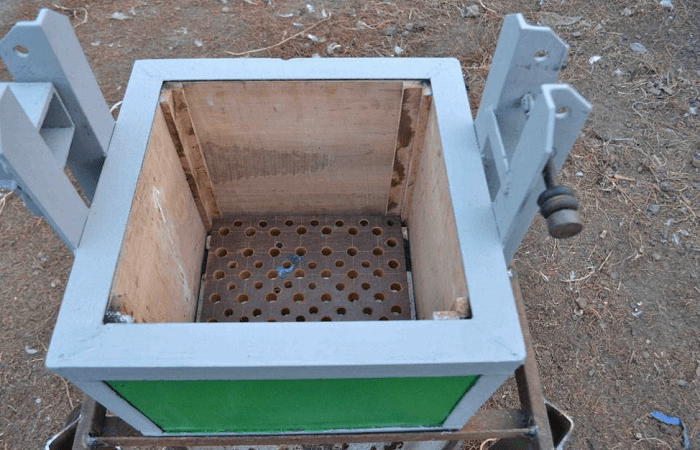

To make your own wax press, you need to prepare materials and tools in advance. First of all, you need to find a large capacity container. Many people use a washing machine drum or other metal structure. It is durable and reliable, unlike a wooden barrel, which is often used by beekeepers. It is difficult to clean, but the main thing is that the barrel swells due to constant temperature changes and high humidity.

The extraction process requires a screw and a steam piston. It is advisable to make the filter from a material that is denser in strength than linen. Sometimes beekeepers prefer to choose burlap for this purpose, as well as gauze folded in several layers.

A non-standard solution is a wax press from a gas cylinder. To retain heat, it is wrapped in wood or foam. The bottom is pre-cut. Stability is imparted with the help of pipes; in addition, it is necessary to provide a drain hole.

For self-production you will need:

- hammer;

- metal saw or grinder;

- grinding and inverter apparatus;

- electrodes.

How to make a wax press with your own hands

A homemade wax press is usually made from scrap materials. It is based on a drum from a machine, cans or a gas cylinder. Two metal containers, one of which will serve as a stupa. It must be sealed.

How to use

The raw materials are placed in a wax press in a durable bag. Under the influence of the screw, the liquid fraction is gradually squeezed out. The cleaned wax comes out through the holes into a pre-prepared container. The waste remains in the fabric.

When working with a manual wax press, it is important to tighten the bag tightly. The tighter it is twisted, the more refined wax is obtained as a result. The wax produced is of good quality, but it cannot be completely squeezed out.