Greenhouses are widely used for growing various crops. In such structures, plants are protected from dust, precipitation and sudden temperature changes. As a result, this can significantly increase the yield and quality of plantings. A do-it-yourself tomato greenhouse is the optimal solution to this issue. Of course, if you wish, you can buy ready-made designs on the market, which are presented in a wide range.

What requirements must a greenhouse meet?

Regardless of whether a ready-made structure will be installed or constructed with your own hands, it must meet certain requirements:

- The greenhouse for tomatoes should be warm. This will allow the earth to quickly warm up under the influence of sunlight.

- The structure must be of sufficient size for convenient planting and harvesting.

- To prevent the structure from coming into contact with the ground, it is better to install it on a foundation. This will avoid corrosion and rotting of greenhouse elements.

- Since classic greenhouses do not have doors, it is necessary to build a removable top part.

- The height can be slightly more than 1 m. As for the other sizes, it all depends on the preferences and capabilities of the owner, as well as the characteristics of the crop being grown.

A homemade greenhouse often consists of a metal or wooden frame, which is finished with film, glass, polycarbonate and other materials.

How to make a greenhouse for tomatoes

It’s quite simple to build a greenhouse or hothouse for tomatoes at your summer cottage. There is no need for large financial expenditures. Of course, the exception is large-scale buildings. In such cases, it is better to use the services of professionals who will solve any problem efficiently and in a short time.

The basis of the greenhouse is a frame that has any shape. It can be triangular, arc-shaped or rectangular. To construct the base, wooden beams, metal corners, fittings, pipes and other materials that have sufficient performance properties are used.

Frame structures

Classic greenhouses are made from identical frames. Their sizes depend on the dimensions of the future greenhouse. Frames are made from wooden blocks or metal corners.The construction of a greenhouse is carried out in several stages:

- A brick foundation is laid along the perimeter of the future building. This will give the greenhouse stability and protect it from contact with the ground.

- The timber and boards are treated with mastic, which will protect the wood from negative environmental factors.

- A timber is placed around the perimeter of the finished foundation. Prepared boards are attached to it using self-tapping screws.

- Boards are attached to the racks on top. After this, the construction of the rafter system is carried out. This implementation will simplify the drainage of condensate.

At the final stage, the frames are attached to the frame. One of them should open, which will allow entry into the building.

Metal buildings

Greenhouses made of metal have a presentable appearance. To construct the frame, a steel angle or pipes of a certain diameter are used. Assembly is carried out using welded or prefabricated methods. This determines whether the building will be temporary or permanent. Thick film or polycarbonate is used as a coating. Metal greenhouses are optimal for growing seedlings and adult plants.

Metal buildings have different shapes. Arc-shaped designs are very popular. But, nevertheless, rectangular greenhouses are considered more comfortable. They can make the most efficient use of every meter of land.

Greenhouse-bread bin: design features

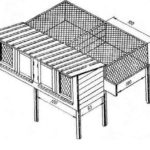

Greenhouses are presented on the market in a wide range. Small designs in the form of a bread box are very popular.

They have many advantages. Caring for plants in such buildings is very easy.This is due to the fact that the constructed greenhouse is equipped with drop-down walls.

Advantages and disadvantages of the product

The advantages of a greenhouse in the form of a bread bin include:

- compactness, which allows the structure to be installed anywhere on the site;

- light weight allows you to easily rearrange the greenhouse if the need arises;

- despite its small size, such a greenhouse can accommodate many seedlings;

- the presence of rising doors makes it easier to care for plants;

- ease of installation;

- relatively low cost.

As for the disadvantages of a greenhouse-breadbox, here are:

- tall plants cannot be grown in such a structure;

- the hinges that ensure the movement of the sash are periodically lubricated;

- Installation of a bulky structure cannot be carried out independently.

It is worth noting that the height of a greenhouse for tomatoes is no more than 1.5 m. Higher buildings are classified as greenhouses. As for the bread box, it is optimal for growing tomato seedlings and other crops.

Classic arched greenhouse

Arched greenhouses are used for growing various crops for a long time. Their popularity lies in the presence of many advantages, among which are:

- ease of construction;

- minimal cash costs;

- versatility and practicality.

You can easily build an arched structure with your own hands. It is worth considering some features:

- The building should be placed so that the end side faces north. This way, the plants will be illuminated throughout the day. And in the midday heat they will be hidden behind the end wall.

- During construction, it is worth considering the width and height of the steam room, which will allow you to choose the right length of materials.

- The length of the steam room can be any, but given the small height, it should not be more than 4 m.

- The arcs should be located at a distance of no more than a meter. This is done in order to give the structure strength.

By following these rules, you can create a strong and durable greenhouse that is suitable for growing not only tomatoes, but also other vegetables.

Greenhouse construction

The construction of a greenhouse on a summer cottage begins with the construction of a foundation. The best option here would be a wooden board or beam. Before use, the material is treated with an antiseptic, which will protect it from rotting. Shields are made from boards and assembled into a box. Its dimensions must correspond to the size of the greenhouse. Self-tapping screws, corners and nails are used for fastening.

Today, greenhouses made of PVC pipes are very popular. After the box is constructed, they begin to install the fittings on which the pipes will be placed in the future. The reinforcement sticks tightly into the ground. The rods should be located opposite each other. To make the process easier, you need to make marks on the box.

The next step is to install the pipes. They are carefully placed on the reinforcement, after which they are attached to the base with plates. At the final stage, the frame is covered with film. It is carefully attached to the box using a construction stapler.

Thus, you can build a simple arched greenhouse for tomatoes with your own hands. Depending on the height, different varieties of tomatoes can be grown in it.