Every farmer would like to know how to correctly calculate the materials for a barn for 10 adult animals with calves. You first need to determine what will be required for future construction. Choose the option and materials that suit you best. On a cattle farm, it is necessary to provide the animals with comfortable living conditions. And provide for all the little things. Then the barn will last a long time and will be beneficial.

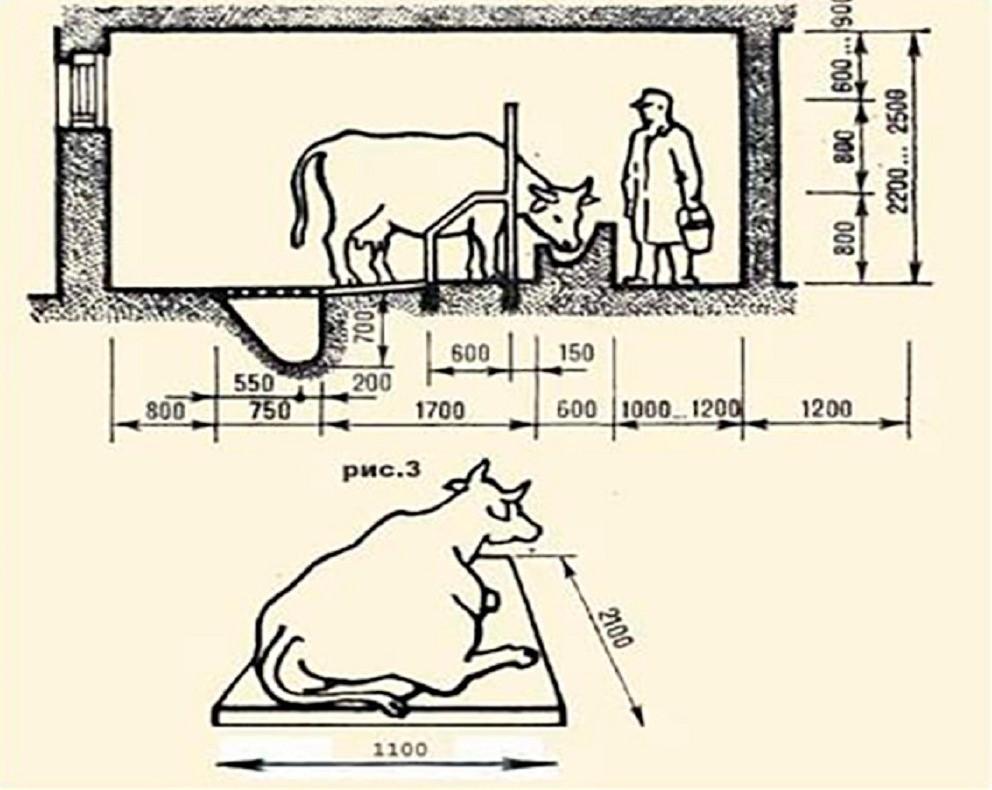

Drawings and dimensions

The dimensions and construction site of the barn are preliminarily determined, and the necessary calculations are made. The time spent on creating a farm project will pay off handsomely, saving a lot of effort, materials and money. The idea for the farm and materials can be your own or borrowed from the Internet. For example, like in the video:

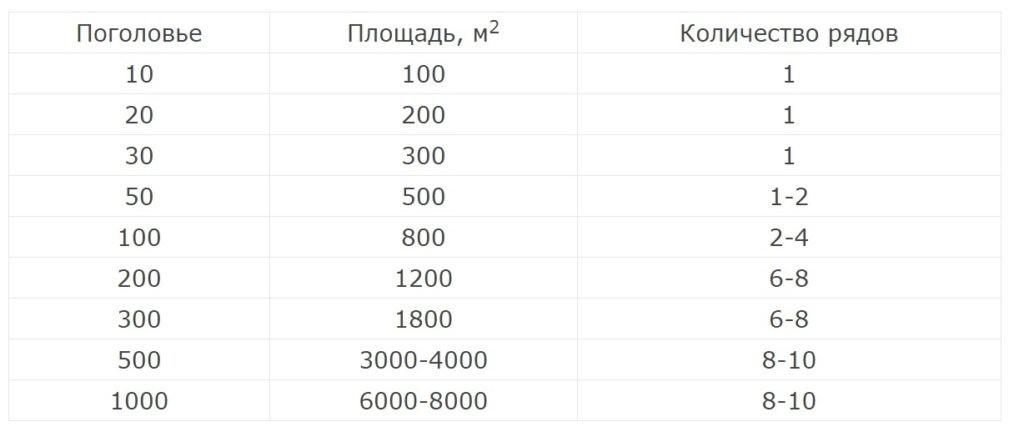

The ratio between the number of animals and the occupied area of the farm must be taken into account (reference data is given in the table):

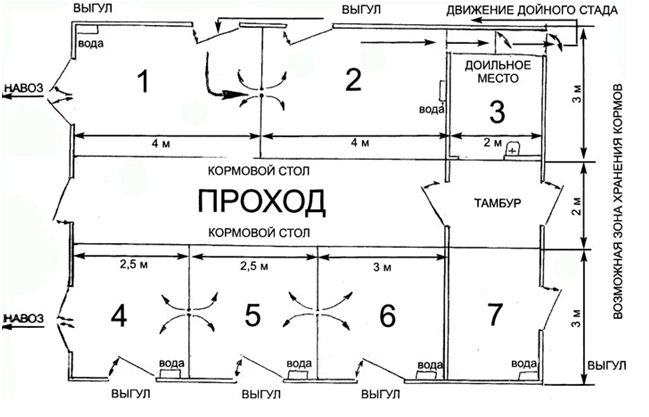

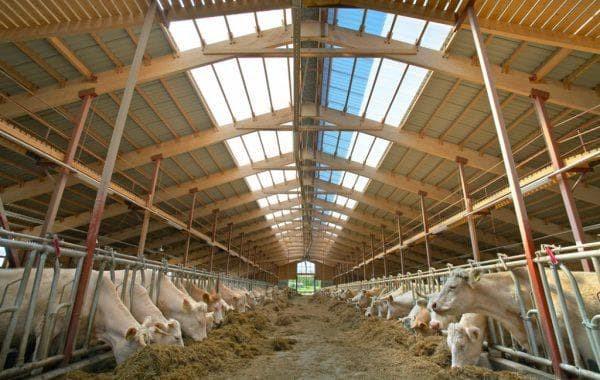

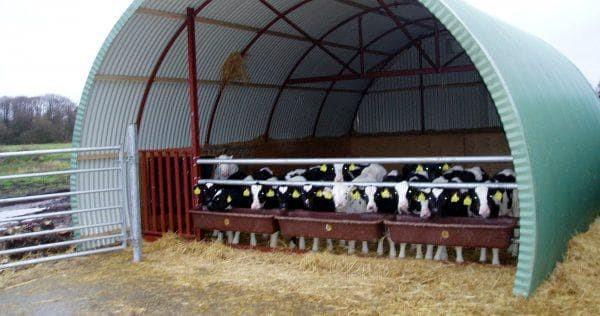

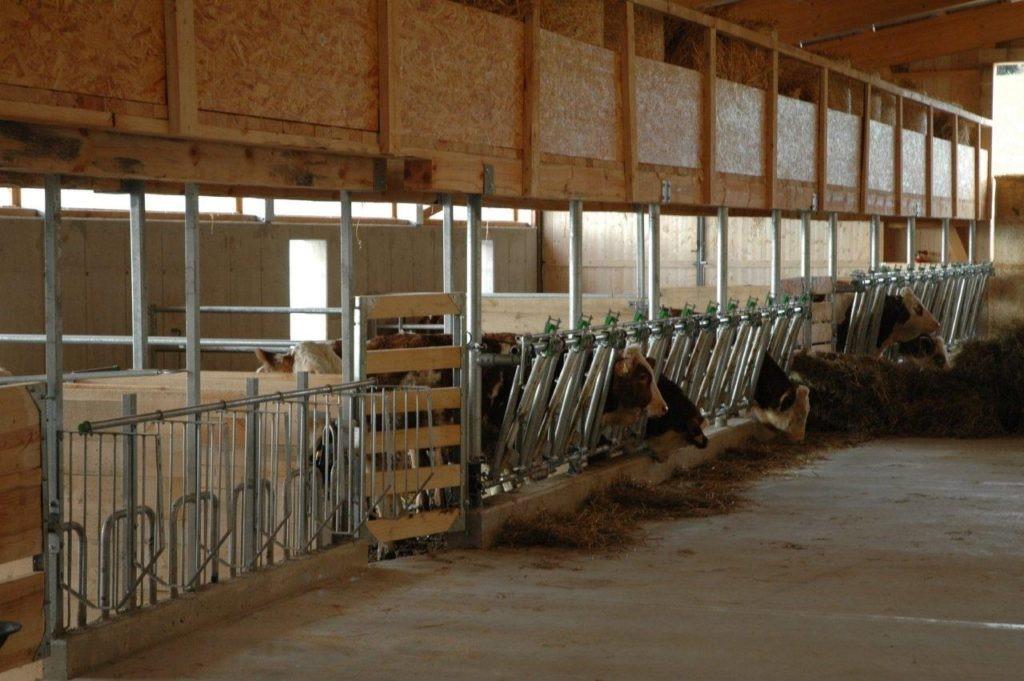

A certain layout of areas for walking, milking, and feeding cows on the farm is used. For example, like this:

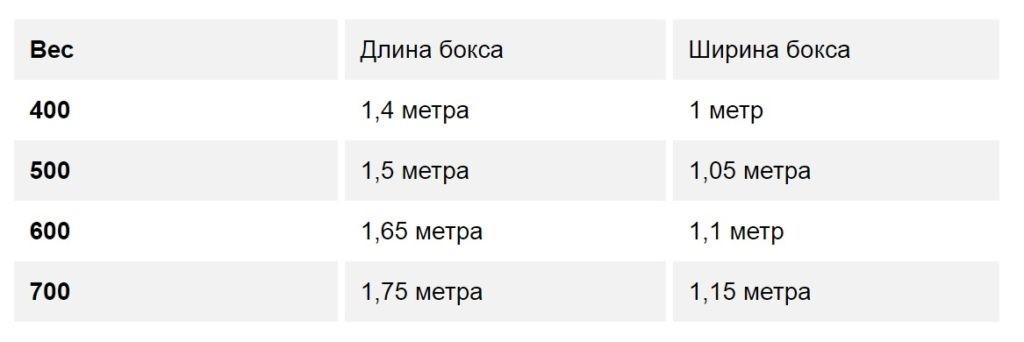

When designing a barn, the basic area and established housing standards are taken into account depending on the weight of the animals:

The more thoroughly it is worked out barn project, the fewer problems will arise during the construction process, arrangement of premises and installation of equipment in the farm pens. Using ready-made solutions is a profitable way to reduce labor costs, without “reinventing the wheel” where it makes no sense.

Moreover, in the tested options barns have already taken into account the required dimensions, communications, layout of window and door openings, including sewerage. All that remains is to select a barn for the required number of animals and begin implementation.

Requirements for a barn

Any building will be this barn for adult bulls or a mini-farm for keeping young animals, must meet specific requirements. This means that there are places in the barn for lying down, feeding, and milking. In summer, the barn protects animals from heat, in winter – from cold and drafts. Cows are sensitive to temperature changes and easily get sick if proper conditions are not provided.

Dividing the barn into separate compartments is a mandatory requirement.Undoubtedly, it is worthwhile to provide separate entrances and exits from each block on the farm, as well as an independent entrance for people. The barn will become for the animals their permanent habitat outside the pasture. Therefore, it is not worth saving on comfort and equipment.

With careful care of the cow, the young animals will begin to gain weight and produce milk and meat. That is, to fulfill the goals that the owners pursued when creating the farm. When choosing a barn design, take into account the capabilities and availability of materials for building a barn. The barn wall material must not only be warm for the winter season, but also have sufficient rigidity and strength. Withstand contact with animals without damage or loss of load-bearing capacity.

When creating small barns, the following materials are most often used:

- slag blocks;

- foam concrete;

- tree;

- brick;

- adobe.

The design of the barn and the material of the walls are selected in advance, at the design stage. Possible replacements and alterations will entail an inevitable increase in the cost of the object.

The foam concrete material has approximately the same properties: it is used to fill wall openings in civil construction, due to its lightness, strength and ease of use. But in rural areas, getting both these materials can be a problem. Just like the widespread brick.

For hot areas with relatively warm winters, adobe may be recommended for the barn. An environmentally friendly material obtained by natural drying of clay mixed with straw, cast into special molds.The disadvantages of adobe are as follows: it cracks in the sun, requires protection from the effects of precipitation, and before starting construction, it is necessary to prepare enough “bricks”.

Wood seems to be a good material option for constructing agricultural buildings. Lightweight, relatively cheap and durable, but not without flaws. Wood is susceptible to rotting, exposure to fungi and pests, hygroscopic, and flammable. Treatment of the material with special compounds will help solve these problems.

The main advantage of wood is the low weight of structures. You can do it with manual labor without using expensive, energy-intensive mechanisms to create a barn. In combination with effective modern insulation, wood will allow you to build a barn quickly, efficiently and not very expensively.

The requirements for the future “cow house” are based on officially approved regulations and veterinary rules. It will not be possible to give up on these circumstances or ignore them: Rosselkhoznadzor will certainly visit future farmers more than once or twice to make sure that the conditions for keeping bulls, cows, and young animals comply with the established rules.

Do not forget what profile the farm under construction will be - meat, dairy or mixed. This circumstance will affect the layout, the number of pens of the barn, and their type. The barn should be located so that it is convenient for transport to approach (the existing road is taken into account or a new one is laid).

You cannot build a barn building in a lowland, where groundwater lies close to the surface. You should not place the farm close to residential buildings: smells and noise will disturb people. And the proximity of the barn to industrial facilities will disturb the cows themselves.According to sanitary standards, the farm cannot be located near water pipes, wells, or reservoirs closer than 20 meters. If a farm expansion is planned in the future, this fact is taken into account in advance. On average, each animal requires about 2.2 square meters of barn space.

Tools and materials

To build a farm or a cattle barn according to all the rules, you will need materials and tools. These include:

- shovels;

- hacksaws for wood;

- hammer;

- drill or screwdriver;

- electric circular saw;

- trowel;

- buckets;

- trough;

- sand;

- crushed stone;

- cement;

- wooden beams, boards;

- nails;

- screws;

- liquid waterproofing;

- impregnation for wood;

- insulation;

- roofing materials.

It is preferable to build a barn for 10 heads from wood. In this case, it is permissible to get by with a minimum of materials and tools. And if you cut the beams and boards to size in advance, there will be no need for a hacksaw or power saw. The construction of stone farm walls will require the construction of a powerful foundation to distribute the load from the above-ground part to the ground.

Wooden truss walls weigh less, allowing you to use a simplified design. The amount of materials is determined not “by eye”, but in accordance with calculations. The standards give the approximate consumption of nails, boards, sand, crushed stone or cement. The material must be taken with a reserve, so that later you do not have to buy more of it or look for a replacement.

Rules for making a barn for 10 heads

To avoid typical mistakes and miscalculations, you should draw up a detailed plan for the construction of a barn, broken down into stages. It will look like this:

- Cycle of earthworks. Planning the construction site, digging a pit.

- Foundation construction. Waterproofing, laying communications (sewerage).

- Walling. Stone masonry or wooden beam structure.

- Creating a slab. Installation of ventilation, wiring, water supply, roof structures.

- Installation of insulation, final finishing, finishing, glazing of windows and hanging doors/gates.

- It is important when carrying out work not to violate the technology, to be guided by the setting time of cement/concrete, and not to proceed to the next stage until the current one is completely completed. Wooden structures are impregnated with compounds against rotting and fire immediately or after completion of work.

If the barn is not built on its own, but by contract, the organization is obliged to provide the customer with all the necessary documents and draw up an acceptance certificate for the object.

Laying the foundation

Building a barn with your own hands begins with laying the foundation. Markings are made at the site of the future farm: pegs are driven into the corners, onto which the cord is pulled. This is how the boundaries of the walls of the building and the outline of the foundation are indicated. The depth and width at the base are determined by calculation depending on the region and terrain conditions. Or they are accepted as standard.

Before installing the slab, it is backfilled with crushed stone, then a sand cushion is installed. These measures are necessary to ensure the stability of the foundation and avoid subsidence. Waterproofing is carried out by coating or pasting. Now water-soluble bitumen mastics are produced, which are convenient to use and easy to apply.

The horizontality of surfaces is controlled by geodetic instruments and the building level. The strength of the strip foundation and resistance to load will be higher if reinforcement with steel rods is used. Their number, diameter and arrangement are determined by calculation.

The formwork for the foundation is assembled from boards. Concrete for pouring is mixed from crushed stone, sand and cement.A concrete mixer or trough of suitable size is used. Until the solution hardens (approximately 72 hours), you cannot proceed to the next step. All concrete work is carried out at above-zero temperatures. Failure to comply with this requirement will lead to poor quality of the foundation, the appearance of cracks and cavities.

Floor installation

The floors are laid when the work of the zero cycle is completed and the foundation is completely set. Of all the possible options, the most preferable seems to be the construction of floors on the farm from wooden boards. Cement and self-leveling ones are not suitable because they are cold and will cause discomfort to the cows. Before work begins, sewerage systems are planned and completed, including drainage trays.

Walling

Before the construction of the farm walls begins, beacons are installed and cords are pulled to determine the verticality and contour of the walls. Compliance with the parameters is periodically monitored - plumb and level.

It is possible to build a barn using a frame method: first the columns are erected, and then the openings are sewn up with boards. The type of farm foundation must strictly correspond to the adopted design and wall material. If replaced, it will be impossible to redo it.

The stage is completed by installing a stiffening belt in the upper level and tying the walls of the truss (supports) with beams. Openings for doors and windows are calculated in advance and placed in strictly designated areas.

One example of barns is shown in the video:

Installation of roof, doors and windows

The design of windows and truss doors depends on the wishes of the customer.The main condition is reliability, the presence of constipation, the absence of gaps and cracks. It is allowed to use finished products manufactured (purchased) in advance, according to current dimensions.

The roof of the farm can be pitched or flat. Type of covering – corrugated sheets, tiles, shingles. It is also determined at the design stage; the required materials are ordered for it. The ceiling between the barn and the roof is insulated to provide comfortable conditions for the animals.

The fastening of the covering (slate, tiles, corrugated sheets) must withstand gusts of wind and perform its main function. Suggested options are nails, screws. For optimal placement of the covering along the beams of the truss, a sheathing is created taking into account the pitch of the elements (sheets, tiles).

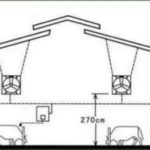

Ventilation

Ventilation is needed not only to get rid of specific odors, but also for aeration and air movement inside the barn. It can be natural, forced, supply and exhaust. They vary in installation complexity and cost. It is built in full accordance with the original design of the barn.

Manure removal system

Cows are herbivores, which produce quite a lot of feces and manure during their life. It is necessary to provide a system of trays embedded in the floor so that the paddock and barn can be easily and quickly cleaned. The installation of complex manure removal complexes, as on large farms, seems impractical.

It will be more effective to build a central trough along the entire length of the barn. It is possible to organize a separate pit for each animal on the farm, but this will require large cleaning costs. The manure storage facility is located outside, in a place equipped with transport access to the farm with the possibility of pumping out.

Lighting

Standard openings in the walls of the barn are constructed at a level of 1200-1500 millimeters from the floor. When installing windows, farms are guided by the rule: 10% of the total area of the barn. It is possible to open for ventilation and washing. Most often, polycarbonate tape and PVC bindings are used.

It is recommended to adhere to the following standards:

- farm stall – 50 lux;

- feeding area – 75 lux.

Cows on the farm need bright light from 4 a.m. to 8 a.m. From about 4 p.m., its intensity is gradually reduced.

Water pipes

Water in the barn is necessary both for domestic needs and for watering animals. The number of drinking bowls and sinks is determined by calculation and the needs of the farm. In winter, the water supply on the farm should not freeze; for this purpose, the pipes are insulated. The diameter is taken such as to provide pressure and throughput. You can get ideas for the farm in the video: