Creating cowsheds in a village or suburb with your own hands, on your own, requires care and careful calculation. Their productivity depends on how well the requirements are taken into account and the conditions for keeping animals are met. It doesn’t matter whether you plan to build a barn for 2 heads or 10. It is imperative to follow sanitary standards and general construction rules.

Types of barns

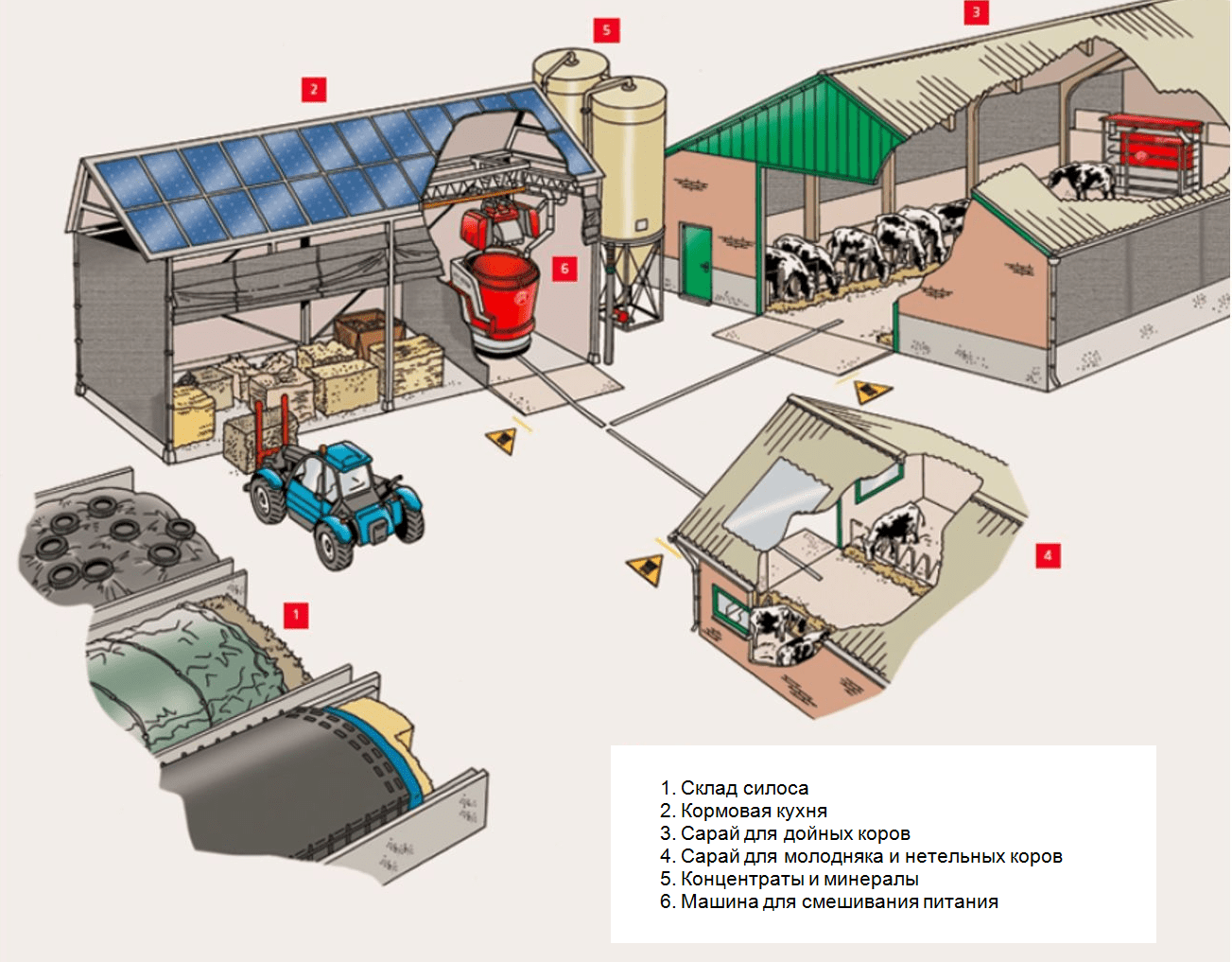

Cowsheds, as free-standing buildings, are classified according to several criteria. First of all, this is the number of animals kept there. There are mini-farms for 3 heads, 10, 20 and more. Large barns can house up to hundreds of animals at a time. It is allowed to combine several functional areas in a building under one roof: for feeding, walking, milking.

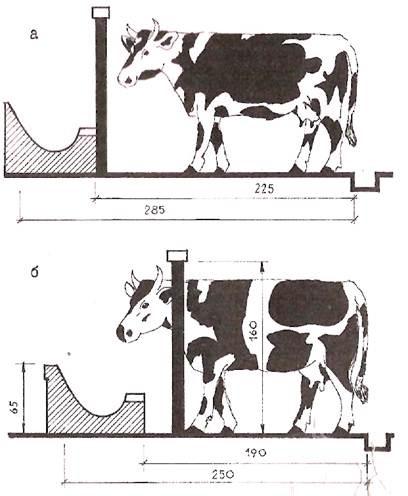

The more animals, the larger the space they occupy. One cow requires 2.3-2.4 square meters (laying area), sometimes up to 6 square meters are indicated. This is the minimum “comfort zone” of cattle on the farm. Standards for building area can be obtained from veterinary reference books; the information is in the public domain.

An example of a barn is shown in the video:

The second factor influencing the configuration of the farm is the direct purpose of the building. It is preferable to separate heifers and bulls, growing and already mature young animals on the farm. Each animal in the barn should have a separate stall, physically fenced off from other areas.

The third criterion relates to the type of barn and climate zone. In warm areas, it is possible to limit yourself to creating a light enclosure with protection from precipitation. In cold areas, you will need to build a full-fledged farm with insulated walls, a vestibule, and a heating system. Separate creation of seasonal barns (light summer and major winter) is justified if large-scale breeding of animals for milk and meat is planned.

In a mini-farm for 3-5 heads, there is no point in building buildings for each season.

Choosing a site for construction

Cowshed with equipped cow stall must be located in certain conditions and terrain.This includes sanitary, geological, and veterinary standards for keeping animals on the farm. It is better if it is a separate building, remote from residential buildings.

It is not allowed to build a barn in lowlands, in wetlands, or close to industrial facilities, factories or workshops. It is forbidden to erect a farm building on the site of former cattle burial grounds, waste disposal sites, or landfills.

The barn should not be located near water sources, wells, pipelines, canals, or wells. The permissible distance from the building is 20-25 meters. Electricity, water supply and sewerage are installed separately to the farm. It is best to choose an elevated, level place for building a barn, with good transport links.

The route for driving cows to pasture, transporting young animals to the barn or taking them to slaughter is also calculated. To do this, a plan for the future construction of the barn is created, where all the “little things” that influence the choice of location are indicated. If it is not possible to build a barn on a separate area, the farm building is integrated into the existing infrastructure, taking into account all the above requirements.

What tools and materials will be needed

Budget options involve construction with minimal consumption of expensive materials, on a reduced-cost strip foundation, using human physical strength (rather than mechanisms or construction equipment).

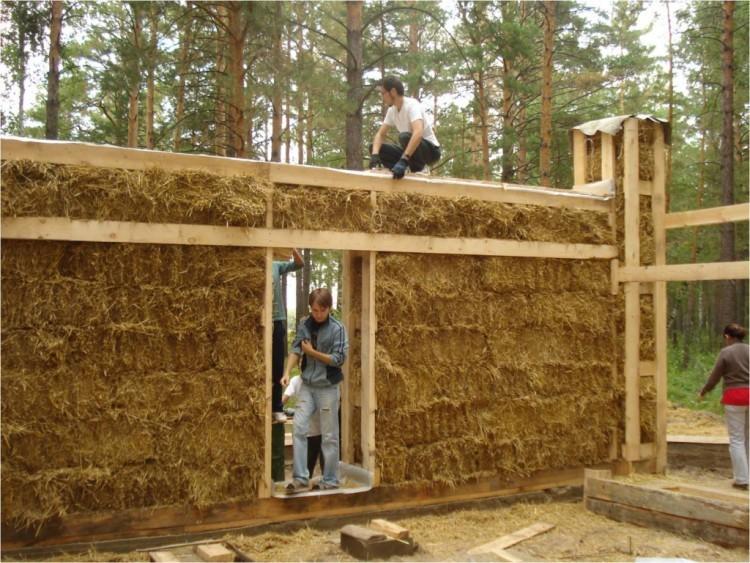

Most often, pine is used to build a farm in the form of boards, timber, relatively inexpensive, affordable and easy-to-use lumber.

An important argument in favor of choosing wood is the fact that it is relatively easy to process by hand. It is not difficult to cut into measured lengths (or order at a sawmill) of the required dimensions and quantities. The wooden parts of the barn are fastened with nails driven in with a hammer, or with screws, metal brackets, or corners.

Both do not pose a problem, unlike assembling a barn from metal structures, where you will definitely need power tools for cutting, stripping, and special equipment for welding. And calculating the metal frame of a barn is technically more complex and requires special knowledge (involving professional designers).

The lumber itself can be taken to the farm not first-class, but with minor defects, knots, or substandard. A small barn for 3-5 animals can be built using a minimum of tools. You will need wood saws (preferably 2-3), a nail puller, and a pair of medium-weight metalworking hammers.

If the foundation pit for the farm will be dug manually, you will need several shovels - bayonet and shovel. Excavation work is one of the most labor-intensive. In addition, before digging, you need to make a breakdown of the area and draw a diagram of the layout of the building’s contours. It is more expedient to create the foundation of the barn from concrete, a practical and durable material. Therefore, you will need crushed stone, sand, cement and reinforcement.

An example of a wooden barn is shown in the video:

When building a large farm, you cannot do without mechanization. Trenches for laying the tape are dug with an excavator. Their depth is determined by the soil freezing parameter. In difficult geological conditions, on subsiding soils, in seismically hazardous areas, it will be necessary to build a pile foundation for a barn.

The soil under the bored piles is selected using a hand drill. You can make it yourself or purchase it. For cold areas, walls and truss ceilings are insulated with some synthetic material (foam plastic, glass wool, roll insulation). There must be a positive temperature inside the barn in winter.

The truss covering must provide protection from precipitation and retain precious heat during the cold season. In the southern regions this may be polycarbonate fixed to the arches. In this case, the barn itself looks like a light pen. For the middle zone and colder regions, the roof of the farm is made of asbestos-cement sheets, metal tiles, and corrugated sheets.

The consumption of materials for the barn is determined by calculation or according to established standards. You can order this part of the project along with drawings and diagrams, and calculate it yourself using special programs.

In addition to the standard set of tools, you will definitely need measuring instruments - a tape measure (folding or electronic), a construction meter, as well as a plumb line and level. They will help you maintain the dimensions of the building and control the parameters.

Drawings and dimensions

It is best to borrow a ready-made diagram of the future barn rather than create it yourself. It must take into account all sizes, dimensions, location of gates, doors, windows. Don’t forget about farm communications: there are strict rules for their installation.

All that remains is to choose a project that suits your own needs, corresponding to the planned livestock, and download the drawings of the barn. It is important to detail the farm building in the form of plans, sections, and individual components. This information will allow you to avoid critical mistakes and complete the construction of the farm efficiently and on time.

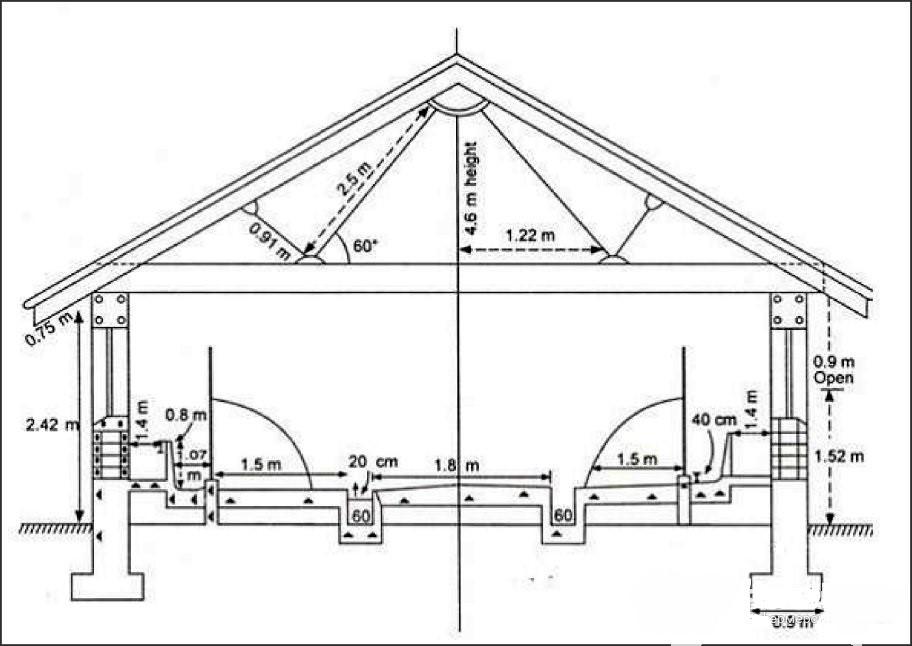

The dimensions of the building are directly related to the number of animals contained in it and its purpose. For large facilities, designed for 50 or more heads, separate stalls are created on both sides of the room, with a central aisle in the middle. (1.2-1.5 meters).

With fewer cows, the through passage in the barn can be made from the side, left or right.

It’s not bad if the building has a utility room designed for people and equipment storage. The width of the farm gate is chosen in such a way that animals can enter and exit freely and without crowding. People use a separate entrance provided. The size of the window openings provides a sufficient level of illumination. Creating a lantern at the top of the barn roof creates an additional source of lighting.

It is convenient that ready-made projects often indicate the approximate consumption of materials. This will eliminate the need to recalculate the standards yourself, manually.

Step by step construction

Professional builders break down the entire construction of a building into stages. This allows you to control every operation, improve the quality of work and reduce labor costs.

It looks like this:

- Layout of the site.

- Foundation.

- Floor, sewerage.

- Walls.

- Roof.

- Filling openings (windows, doors).

- Ventilation, electricity, plumbing.

Step-by-step implementation of procedures greatly simplifies the process itself and speeds it up.

Step 1. The construction of a barn begins with the selection of a site and its layout. Next, the building site is broken down. This may require a specialized tool (if the object is large). For compact barns, a tape measure will be sufficient.

Pegs are driven into the corners of the future building, onto which a white cord (sold in hardware stores) is pulled.Then they move on to the next stage - the zero cycle.

Step 2. Digging a solid pit for a farm is impractical because it increases labor costs and requires the use of machinery.

It is allowed to make trenches in the locations of the strip foundation under the main (load-bearing) walls of the barn, while controlling the depth of the pit. The choice of foundation design depends on the soil and the scale of the building. Strip or pile foundation options are used.

Step 3. When the concrete has set, they begin to build a drainage ditch - it is needed to eliminate the waste generated during the raising of cows. Then the farm floors are laid.

Step 4. When installing truss wall structures, regardless of their type (wooden, brick, on a metal frame), verticality and compliance with the design dimensions are controlled.

Step 5. After completing the walls of the barn, they move on to the ceiling (covering). This is the part of the building that provides rigidity in the horizontal plane. It is possible to create an attic or technical floor where the required communications, including ventilation, will be located.

The choice of building roof design affects the materials used and their consumption. For a gable roof, you will need to construct purlins and maintain the slope. In small barns, a flat roof at a slight angle to allow rain to drain off is sufficient.

Step 6. When the “box” is completely finished, you can begin to arrange window and door openings and lay communications. This completes the construction of the farm.

Foundation

It is impossible to build a barn building without a foundation. This is against building codes and is also unsafe. If it is possible to use a tape structure as it is cheaper, it should be used.The depth of placement is determined according to regulatory documentation and is tied to the climatic region.

The amount of reinforcement, its pitch and profile are determined by calculation. As a last resort, they are taken from a standard project. It is impossible to do without reinforcement; this reduces the bearing capacity of concrete several times. Before pouring, the locations for laying sewers and drains are marked. Then the formwork is installed in the prepared trench and the reinforced frame is laid.

The poured concrete mixture gains 30% strength after 72 hours. This indicator depends on the brand of cement, temperature and humidity. After the specified period has expired, you can proceed to the next stage.

Floor and gutter

Wooden floors are preferable to others because they can be made independently, with a minimum of cost and experience. Logs are laid in front of the flooring. These are wide boards or even cuttings of the upper part of the logs (slabs) to which the floorboards will be attached. There must be an air gap between the joists and the ground so that the wood does not rot.

Don’t forget to impregnate the wood, so the structures will last longer. The gutter is installed directly in the floor with its walls lined with metal, brick or cement mortar. This measure is necessary to avoid seepage of wastewater into the ground.

The outlet of the ditch ends outside the building, in a cesspool or manure pit. A slope should be provided so that feces from the farm flows into the container by gravity.

Walls

Before building a barn or barn, choose the design of the walls. It is easier than others to build structures made of wood.

It doesn’t matter whether it’s solid wooden panels or cladding along the frame of the truss, verticality and compliance of the dimensions with the design ones must be controlled.

Openings for windows and doors of the barn are constructed in strictly designated places. If you miss this circumstance when constructing the walls of the farm, you will have to interrupt the work later to eliminate the error.

The method of fastening barn structures must provide the required rigidity and stability. There is no need to skimp on nails, screws, or corners.

Roof

The installation of the covering completes the construction of a wooden barn, not counting the installation of communications and filling of openings. Beams connect the walls of the building together, forming a single structure. Depending on the chosen option, a pitched, flat roof or with a skylight is constructed.

Each type requires specific calculations, so it is selected in advance. The roof is laid directly on top of the load-bearing structures of the truss covering. For sheets, metal tiles, slate, you will have to make a lathing - this way you can secure the material and connect it to the building’s covering.

Windows and doors

The number of windows in the barn is determined by calculating the illumination. The number and size of doors depends on the number of livestock and the needs of the owners. The design of window sashes in a farm building should provide the possibility of ventilation and opening.

The main requirements for doors in a barn are strength, reliability, and the presence of locks. The hinges must be able to easily support the weight of gates and leaves. The most popular materials are wood and PVC.

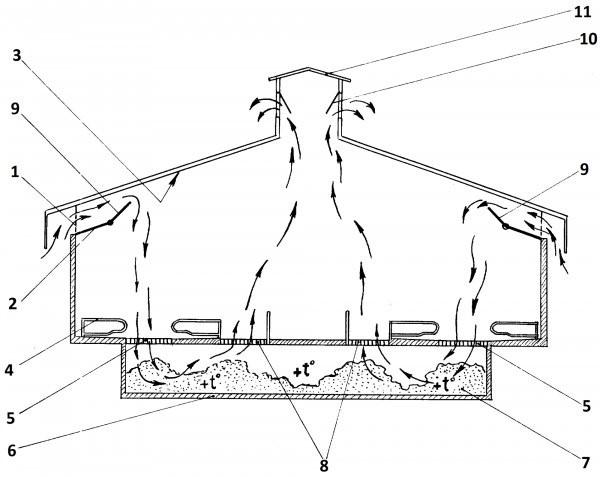

Ventilation

Regardless of the size or type of barn building, it needs ventilation. According to a simplified scheme, the inflow (supply) of air occurs from vents or special intakes, the outflow through the fungus in the roof of the farm (forced by a fan).

This solution will ensure sufficient aeration and animal health.

Communications

The installation of the required communications in the barn is carried out in accordance with the needs of the animals and owners. There should be minimal lighting, water, electricity and heating.

They are laid down at the design stage. For large farms, provision should be made for equipped connection points for milking machines, electric heaters, cleaners and other equipment.

Tips and tricks

When choosing wood as the main material, the following are taken into account in advance: the number of “tenants”, the pitch of the racks in the frame, which depends on this parameter, the height of the barn, the cross-section of the load-bearing elements. It is allowed to use laminated veneer lumber, splicing beams or crossbars.

Bored piles in the foundation of a farm are more economically profitable in relation to driven ones. The depth of their placement is related to the load from the walls, their type (wooden, brick, blocks). The use of wooden piles in a barn is undesirable for the reason that a tree immersed in the ground will relatively quickly become unusable and rot.

If it is planned to simultaneously keep a large number of animals in the barn, additional functional premises of the farm should be provided. For example, such as an isolation ward for sick cows. If there are young animals in the barn, as well as recently calved animals with cubs, they are also allocated a separate area.