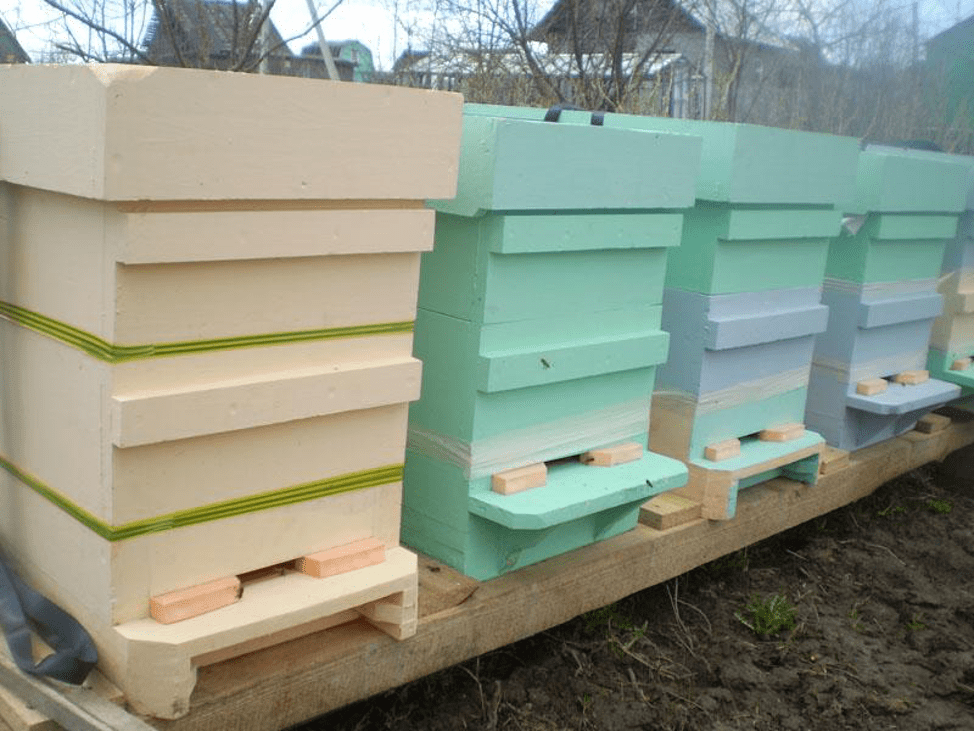

About 30 years ago, beekeepers began using various synthetic materials to build bee houses. There is no consensus on the advisability of using artificial blocks among beekeepers, so beginners are advised to independently study the advantages and disadvantages of such structures. Hives made of polystyrene foam are found quite often in modern apiaries.

Pros and cons of using polystyrene foam

The positive aspects of bee houses made of penoplex are as follows:

- the material weighs a little, which makes transportation and assembly of buildings easier;

- Expanded polystyrene is inexpensive, which significantly reduces the cost of honey production and caring for bee families;

- The material is quite durable (compared to others).

Attention! One of the main advantages is that the houses have high ventilation, soundproofing and thermal insulation properties. Inside the bees are warm, dry, not noisy - comfortable.

The buildings are easy to repair, the parts are quickly assembled and disassembled, and are interchangeable. The dwellings are durable and have a long service life. The disadvantages include the following points:

- hives must be protected from rodents and birds;

- the surface is not easy to clean from propolis;

- in some cases, condensation begins to accumulate at the bottom (you need to monitor this moment).

In addition, bee homes are not easy to disinfect. It is necessary to monitor the condition of the bee colony, possible diseases and infection with mites or viruses. More details about hives in the video.

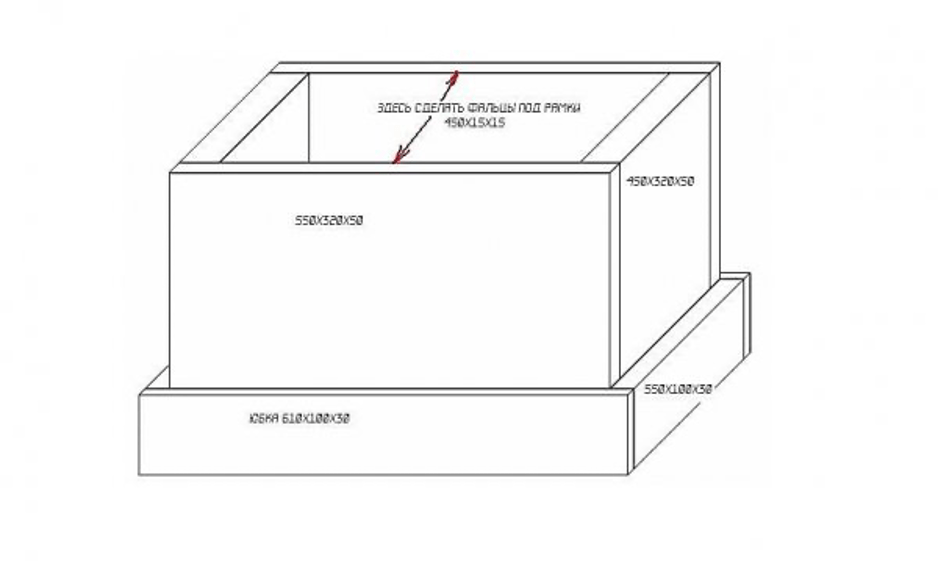

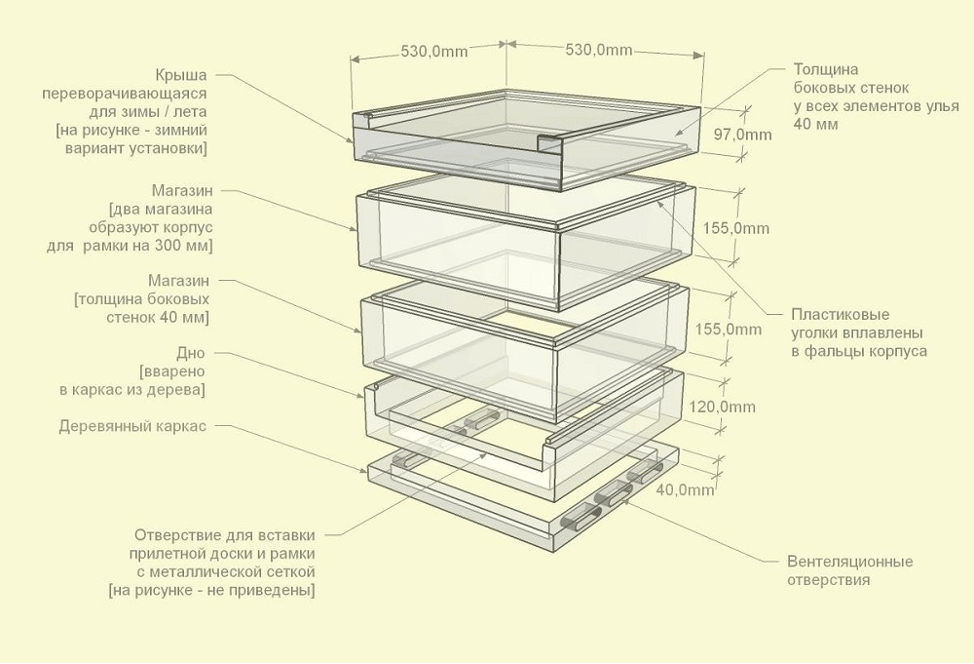

Drawings and dimensions

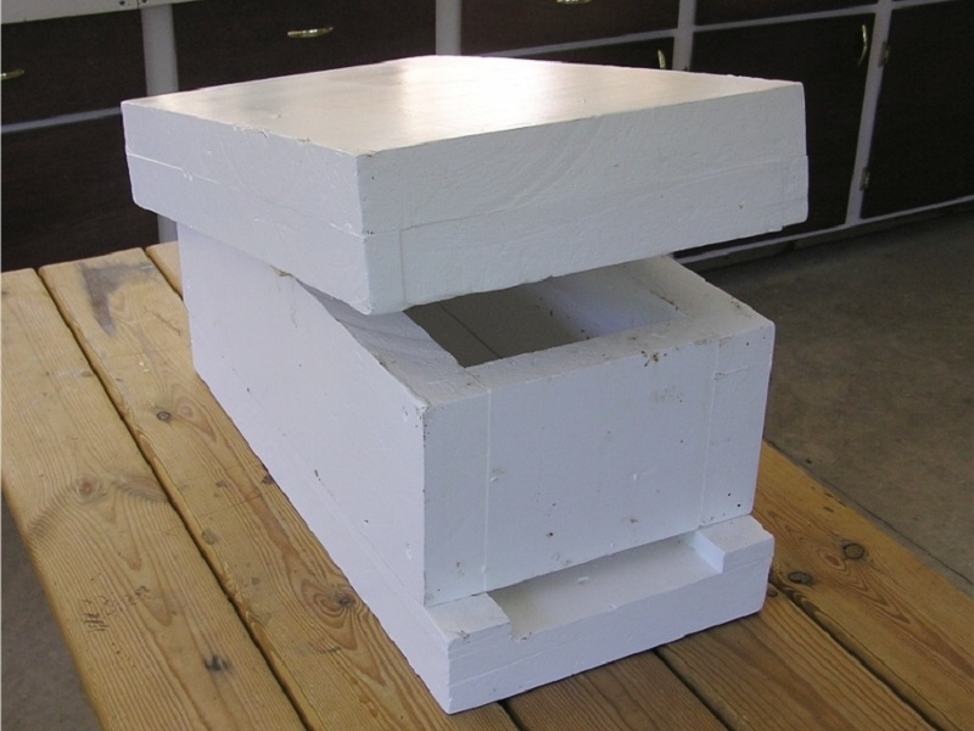

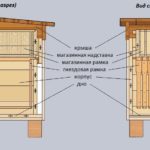

The parameters of the buildings depend on what format of bee care was chosen by the beekeeper. The 10-frame Dadan hive is usually built according to the following dimensions:

- side parts – 32 cm by 37.5 cm;

- walls (including front and back) - 32 cm by 55 cm;

- lower part – 47.5 cm by 10 cm by 3 cm;

- internal – 45 cm.

For frames, folds of 1.5 cm by 1.5 cm must be provided. The standard width of the Dadanovsky profile is 43.5 cm. The following parameters are suitable for a medium-sized beehive:

- body – 50 cm by 58 cm by 108 cm;

- standard number of frames – 24 pieces;

- frame dimensions – 43.5 cm by 30 cm.

Attention! Dadan beds and hives are used in Russia more often than others.Easy care and a familiar design allow novice beekeepers to quickly navigate the process of keeping bee families. But you can use other options.

Making a hive with your own hands

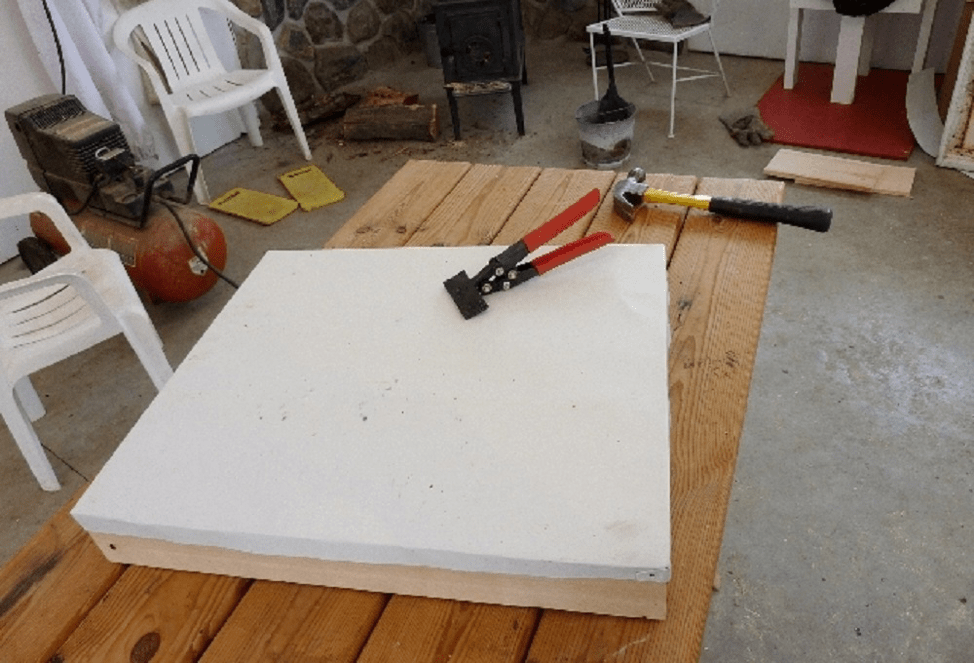

In order to independently assemble a hive from PPS - a collapsible 10-frame hive - you need to prepare the tools and materials according to the list:

- expanded polystyrene - medium sheets, 120 cm by 55 cm by 5 cm;

- paint (water-based, usually white, but other colors are also possible);

- machine for cutting PPS;

- glue, tape measure, stationery knife, marker, wood screws;

- metal mesh with a cell of 3.5 mm;

- plastic corners (1 cm by 1 cm, 2 cm by 2 cm);

- wooden blocks;

- screwdriver and electric jigsaw.

Tools are prepared in advance and checked for functionality. For assembly you will need a large, clean workbench.

Attention! Some experience will be required to operate power tools. It is important to follow safety rules when handling - devices must be in good working order.

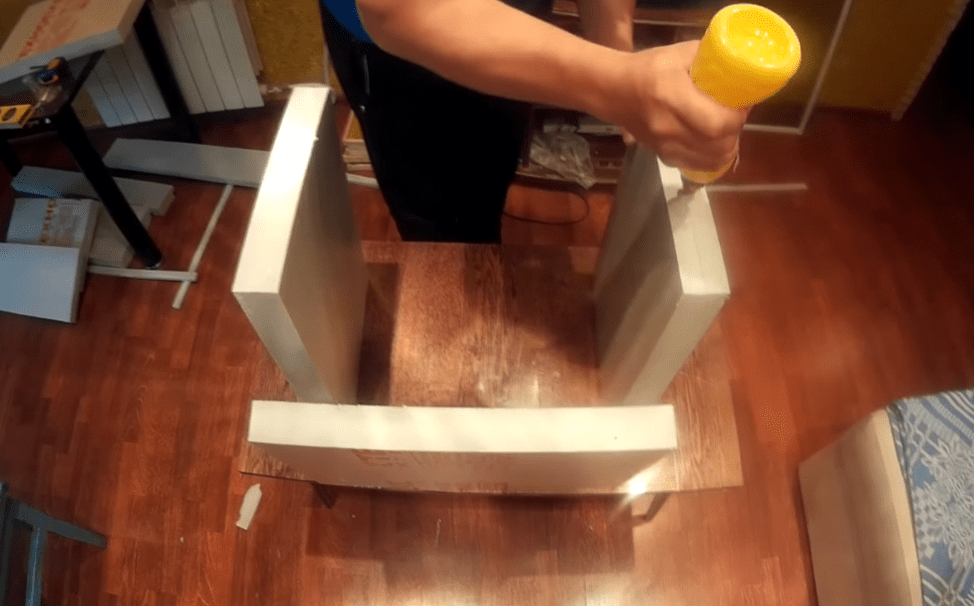

Assembly is carried out according to the instructions given:

- select suitable drawings;

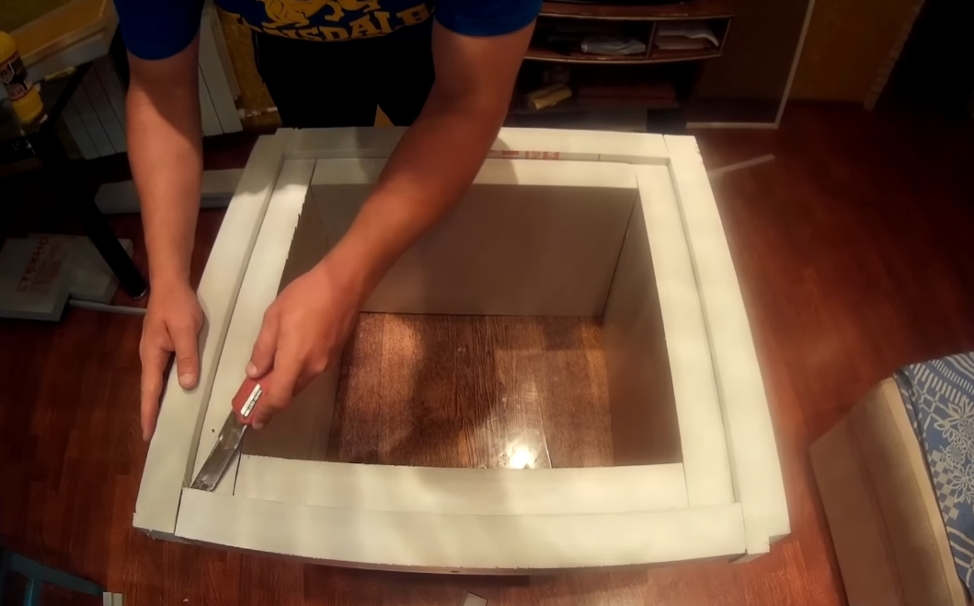

- Apply markings on the PPS using a ruler and marker;

- After cutting, start assembling. Attention! It is important to apply glue liberally to the edges of the parts. After cutting, the sides turn out to be uneven, in order to reduce the number of cracks and drafts, they are smoothed by applying an adhesive mass;

- additionally, the parts need to be fastened with self-tapping screws;

- assemble the “skirt” of the bee house;

- secure the plastic corners;

- cut openings on the sides for carrying (not all the way through).

Before cutting elements, it is necessary to double-check the dimensions and their compliance with the drawings. Using a building level will help you assemble a level, stable structure.Learn more about the assembly nuances in the video.

Tips for use

Keeping bees in PPS hives has some features:

- it is necessary to make the structures heavier (especially if the houses are left to spend the winter outside);

- Condensation may accumulate inside, which can cause mold to develop on the walls of the building;

- In some cases, disinfection can be carried out with a blowtorch;

- It is necessary to leave holes for ventilation so that the air inside does not stagnate, but also does not freeze.

In addition, you need to take into account the peculiarities of keeping the selected breed of insects. Beekeepers note that in houses made of PPS, bees do not gather in a ball in winter, but continue to move.

Beekeepers use different materials to build hives. Expanded polystyrene is inexpensive, easy to handle, and accessible. Beekeepers can assemble different designs from PPS, taking into account standard sizes. It is worth studying the features of assembling and caring for bees in advance.